FeSi 72%&75% With Chinese Origin Export

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

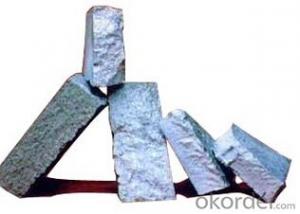

Ferro Silicon 72% & 75%.It is used extensively in the steel-making, casting non-ferrous metals and other industrial production.I

1, Features:

The appearance of Ferro Silicon is the grey lumpish solid. It has very strong stabilities and does not place any chemical reaction in the dry air.

2, Application:

It is used extensively in the steel-making, casting non-ferrous metals and other industrial production.It is the good deoxidizer and most steel kind use the Ferro Silicon for deoxidization;

In steel smelting, it is used to sedimentary accretion and expanding deoxidizing.It is used to prove the strength, hardness and elasticity of steel greatly in steel casting.

Grade | Chemicals Composition(%) | ||||

Si | Al | C | S | P | |

%(min) | %(max) | ||||

FeSi 75% FeSi 75% FeSi 72% | 75 | 0.5-1.0 | 0.15 | 0.02 | 0.04 |

75 | 1.5-2.0 | 0.20 | 0.02 | 0.04 | |

72 | 1.5-2.0 | 0.20 | 0.02 | 0.04 | |

FeSi 70% | 70 | 1.5-2.0 | 0.20 | 0.02 | 0.04 |

Lump size | 10-50 mm, 50-100 mm,10-100 mm, 50-150mm: 90%min, or at customer’s option; | ||||

Packing | In jumbo bag about 1MT/bag | ||||

FACTORY:

- Q:How to solve the severe wear of the flank of the carbide blade during machining?

- 2. Contact the company or log on to the company's website for communication.Carbide inserts are made of hard alloy, an alloy made from refractory metals, hard compounds, and bonded metals by powder metallurgy.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.

- Q:What are the main items of cemented carbide production process and finished products inspection, as well as the price of testing equipment, equipment and equipment?!! Please experts advice and answer, the younger brother will be grateful!!!!!!

- The school's equipment, the majority of the real carbide testing equipment used to study and learn from students, is not equipped with what you see,If you want the most common words, use the following set of scenarios1, magnetic, magnetic saturation instrument, there are also Hunan Normal University2 domestic Hengping density meter3 Ji'nan test the strength of machine4 Rockwell hardness can be used in Shanghai material factory5 Shanghai 5 optical microscope can also plant or lightMetallographic sample preparation equipment can be used in Shandong, Laizhou6 carbon oxygen equipment can be used by Beijing ng7 Scott velocity loose can only buy Beigang HospitalIf you want a mid-range or advanced point, you can add me to chat, and rest assured that I am not selling equipment, and in this line I have been doing it for 10 years

- Q:Several hard alloy cutter lathe with?

- YG car, pig iron and so on, YT, steel and the like, high temperature resistant, YW car alloy steel, the highest strength.

- Q:What are the types and specifications of carbide cutters?

- Classification and grade of common cemented carbide (example)Tungsten cobalt carbideThe main ingredients are tungsten carbide (WC) and binder cobalt (Co)The brand is from "YG" ("hard cobalt" Pinyin prefix) composition and percentage of average cobalt content.For example, YG8 is a tungsten cobalt carbide that represents an average WCo = 8% and the remainder is tungsten carbideTungsten, titanium and cobalt carbide

- Q:Use of waste cemented carbide

- Two, crushing methodFor hard alloy containing drilling is not high, because the hardness is relatively low, can use manual or mechanical means broken to a certain fineness in wet grinding mill for a period of time, to reach a certain size for reproduction of hard alloy. This force is a method has the advantages of simple process, short process, low energy consumption, no pollution to the environment, but often in the manual crushing hard alloy, metallic materials due to debris into the tools have broken material pollution, in addition, due to the hard alloy drill containing high amount of easily broken, mechanical crushing method is very limited; cemented carbide complex material by this method is also very difficult to ensure the quality of recycled products. Process method: artificial crushing is broken, crushed into powder 200 mesh or using bulk of hard alloy ball mill for crushing strikes the ball, then add in the bjm alcohol in wet grinding, and then enter the remanufacturing process of hard alloy.Some companies use cooling method: first crushing waste hard alloy in a muffle furnace heated to 80 above this immediately into the water quench, resulting in hard alloy cracking, and then enter the mechanical crushing process. This force is a method in the last century in 90s in Hebei Province Qinghe to gain popularity, there were dozens of county size ranging from recycling plant using the recycled and processed hard alloy, hard alloy processed over a thousand tons of annual production, the total output value of 300 million yuan, becoming one of the local pillar industry. At present, there is still a certain space for development of the crushing method, and the crushing method still needs to be improved by adopting more advanced and clean crushing equipment or by means of the force method which does not destroy the microstructure of cemented carbide with high efficiency.

- Q:What type of carbide is the most ductile?

- Cemented carbide material with tungsten and cobalt carbide toughness is better, at present the carbide grade in the most toughness of YG15. The relation between cobalt content and toughness is shown below. It can be seen that cobalt content and 13%-16% toughness are the best. In this interval, only YG15 cobalt content is 15%.

- Q:belong to raw material? After buying instockroom directly under the workshop to account for 5The company is small, no warehouse, do not fill in a single storage, the parts purchased directly to use, how to do?It's so complicated. Is there a simple way to do it?

- The key depends on what product you produce, because it will determine the results of your accounting process. In the case of production machinery, the rest of the line will go directly to the manufacturing cost unless the wire is used for raw material handling; otherwise, it depends on the specific circumstances. It's not demanding, anyway

- Q:How are cemented carbides separated from the cutting tools?

- The hard alloy cutter head and the tool body junction part are heated to 600~800 degrees, and the solder can be melted, and the cutter head and the cutter body of the carbide cutter can be separated.Cemented carbide is a kind of alloy material made by powder metallurgy process of hard metal and bonding metal of refractory metal.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials.

- Q:Have seen many of the whole alloy cutting tool brand, I would like to ask, the global overall alloy cutting tool brand, which have quality and price advantage, I want to be a cheap brand regional agent!

- Haili toolsXixia villa brandXixia villa knives accounted for 30% of the national market, the most important city brand

- Q:Can ceramic tools process cemented carbides?

- No, ceramic cutters are usually used to process cast iron (high speed machining) and high hardness steel (Cui Huogang).Generally, the hardness of ceramic tools reaches HRA91-95, while the hard alloy can reach HRA93.The main components of ceramic tool materials are Al2O3 with high hardness and melting point. Si3N4 and other oxides and nitrides, and then added a small amount of metal carbide, oxide or pure metal additives, formed by pressing, sintering, and then a tool material. Its hardness can reach HRA91 ~ 95, and the hardness of HRA80 can still be kept at the cutting temperature of 1200 DEG C. In addition, the chemical inertia is large, the friction coefficient is small, and the wear resistance is good, and the service life of the processed steel pieces is 10~12 times of that of the hard alloy.Its major disadvantages are brittleness, low bending strength and low impact toughness. Therefore, it is mainly used for semi finishing and finishing, high hardness, high strength steel and chilled cast iron and other materials. Commonly used ceramic cutting tools are alumina ceramics, composite alumina ceramics and composite silica ceramics.Taiwan is hard gold metal carbide with high heat resistance and high wear resistance (WC tungsten carbide, titanium carbide, tantalum niobium carbide TiC TaC, NbC etc.) and metal binder (cobalt, nickel and molybdenum) powder metallurgy products under high temperature sintering. The hardness of HRA8 9 ~ 93, 850 ~ 1000 DEG C high temperature resistant, has good abrasion resistance, allowing the use of the cutting speed can reach 100 ~ 300m / min, can be a variety of materials including machining hardened steel, therefore it is widely available.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FeSi 72%&75% With Chinese Origin Export

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords