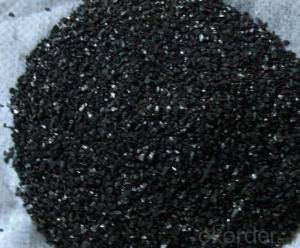

FC 94% MIN Calcined Anthracite Coal

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Professional Manufacturer,exporter of Calcined Anthracite Coal;

High quality with best price.

Calcined Anthracite Coal

• Calcined Anthracite Coal Feature:

All of our goods are made in the best quality with high carbon, low ash, low Sulphur, low moisture.

• Calcined Anthracite Coal Application:

Calcined anthracite coal/gas calcined anthracite coal/carbon raiser is mainly used in steelmaking in electrical stove, screening water, shipbuilding sandblast to remove rust. It can reduce the cost of steelmaking effectively by replacing the traditional petroleum coke of carburant. Also, it can improve the carbon content in steel melting and ductile iron foundry.

• Calcined Anthracite Coal Specifications:

Item | Fixed Carbon %(min) | Ash %(max) | Sulphur %(max) | Moisture %(max) | Volatile %(max) |

FQ-95 | 95 | 4.5 | 0.25 | 0.3 | 1.0 |

FQ-94 | 94 | 5.0 | 0.25 | 0.3 | 1.0 |

FQ-93 | 93 | 6.5 | 0.30 | 0.5 | 1.2 |

FQ-92 | 92 | 7.0 | 0.30 | 1.0 | 1.2 |

FQ-90 | 90 | 8.5 | 0.35 | 1.0 | 1.5 |

Size: 0.5-3mm, 1-4mm, 0.5-4mm, 1-3mm or as customers’ requests. | |||||

• Calcined Anthracite Coal Package:

In 25kgs or 50kgs small bag of single packing;

Or small bags onto pallet or Jumbo bag;

Or as customers’ requests.

- Q:One of my colleagues, do a mechanism charcoal processing plant. Less knowledge of the mechanism's role, uses, and sales channels.

- A charcoal mechanism widely applies to: 1, metallurgy (iron reducing agent, electrode, aluminum ingot thermal insulating agent; 2), chemical (for the production of carbon disulfide, calcium carbide, carbon tetrachloride, etc.); 3 buildings (concrete special filler, insulating material, refractory material, etc.);

- Q:How to calculate the investment of coal

- Upstairs two is not mining, do not mislead people ah!

- Q:Why is heating charcoal poisoning??

- 1 the use of charcoal stove in the house must open the window ventilation, to ensure the flow of air.2 in case of carbon monoxide poisoning, should temporarily leave the poisoning site, breathe fresh air, call someone to help.3 officers found poisoning, should immediately open the window, the patient carried away from the scene, loosen buttoned, maintain airway patency and warm.4 if vomiting should make the patient head to one side, and timely cleaning the nasal cavity secretions.5 people with hand pinch poisoning, Zusanli, Neiguan and other points in a timely manner oxygen, such as suffocation, immediately artificial respiration and chest compressions.6 rushed to hospital for treatment.

- Q:What is the specific coal chemical

- The process of converting coal into gas, liquid and solid fuels and chemicals from coal. Mainly including coal gasification, liquefaction, distillation, as well as tar processing and calcium carbide acetylene chemical

- Q:Bamboo charcoal bag placed in the room

- If you want to live in as soon as possible, there are several methods to help: 1 to half a catty Black Tea soaked with boiling water, the water drained, Black Tea will put a pot (that is, table container area comparison), placed in the room, or directly on the furniture inside, the surface of tea has strong adsorption capacity, can absorb indoor harmful gas as the size of the room, can get many pots. Place more than 24 hours, there will be significant improvement. More than and 2 some green plants, such as Chlorophytum, Sansevieria, ivy, also have the effect

- Q:We want to barbecue, but will not give birth to charcoal, tossing more than an hour did not point, please help my brother and sister, thank you ~!

- Set a small charcoal on the third floor, the flame from the carbon hole out.With the fan at the bottom of the fan, accelerate the burning of charcoal, charcoal will ignite after a few minutes.

- Q:Larch wood which do machine-made charcoal

- Again, look at the copper parts. Old mahogany furniture copper parts if it is original, should be hand over several decades or even centuries. The copper works including the page, hinge, hinge, handle, wrap angle, strip, locks and other materials, some good furniture will choose Cupronickel make, a long time will pan out faint silver, xiasi.

- Q:White melon seeds produced by the mechanism of carbon why taste

- Raw materials of ordinary charcoal is generally mixed, this is the original charcoal charcoal, more environmentally friendly, without any chemical additives, if used in the barbecue is a smoke-free non-toxic, combustion time in 1.5 hours; it is wood charcoal residue, peanut shell, straw who do, and binder. Toxic, burning time in 1-3 hours, but now some manufacturers production mechanism of carbon by high pressure pressing process, adhesive usage can be ignored; charcoal is the best on the market now binchotan, is growing at an altitude of 2000 meters above the tungsten oak trees in accordance with the Japanese side experts in the design of binchotan charcoal kiln from this, binchotan completely smoke-free non-toxic, combustion time in 5 hours, and 1100-1200 degrees in the fire, with far infrared function, you can make for a barbecue Our food is more delicious.

- Q:I was in the washing machine when accidentally dropped the activated carbon into the water that point, put it out. Pour a little bit of black particles found, but not careful to drink Know please say

- Drink only once is nothing, the body will be out of its metabolism, the body itself is not a carbon side effects, do not worry

- Q:There are several types of coal

- Bituminous concrete is divided into: lean coal, lean coal, lean coal, coking coal, fat coal and 1/3 coking coal, gas coal, gas coal, 1/ 2caking coal and weakly caking coal, non caking coal and long flame coal.Lignite is divided into:Brown coalBrown coal two

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FC 94% MIN Calcined Anthracite Coal

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches