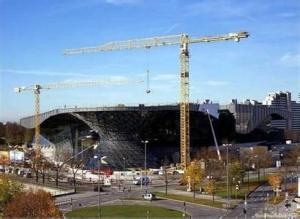

TOWER CRANE PT7023 with safety monitoring control system

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The flat top tower crane is more and more popular among customers with its beautiful appearance and quick and safe disassembly, and its application range is also expanded constantly. The PT series product is the new product with domestically advanced level and capability of international market competition, and the main models include PT5510-6t, PT7023-12t and PT7528-18t. |

1. The lifting boom and balance boom adopt cantilever boom structure, which reduces the hoisting modular and makes it more safe, convenient and flexible to install and uninstall, and reduces the requirements for hoisting equipment and the site.

2. Multiple special mounting brackets are available, which saves the installation time and ensures safe and quality installation.

3. The lifting boom adopts cantilever boom structure and variable cross-section materials, featuring more reasonable structural stress and long service life; and it is easier to make different combination of boom length.

4. It adopts standard sections (for models of over 12t) of piece assembly structure, split structure stock, and assembled platform, which meet the transport requirements for standard container.

5. The extra-long boom is designed with a rope-supporting trolley, and the speed of which is 1/2 of that of the luffing trolley, which can achieve the most optimum rope-supporting effect. The structure has applied for national patent.

6. The lifting mechanism adopts speed regulation by frequency control or by eddy current brake series resistance, featuring good lifting performance; The slewing system adopts frequency control by torque electric motor or by coil winding type electric motor with hydraulic coupler, featuring smooth operation and small slewing impact.

7. All kinds of safety devices are reliable and easy to adjust; both the safety monitoring control system and traditional safety system are available, the double system ensures safety operation of the tower crane; the hydraulic system adopts low/medium pressure design, featuring higher safety and reliability.

Model | Max.lifting capacity & work range | Max.work range & lifting capacity | Max.independent lifting height(m) | ||

Lifting capacity(t) | Work range(m) | Work range(m) | Lifting capacity(t) | ||

PT5510 | 6 | 12.7 | 55 | 1 | 40 |

PT7023 | 12 | 18.1 | 70 | 2.3 | 50 |

PT7528 | 18 | 16.8 | 75 | 2.8 | 60 |

- Q:I just seen pics of a crane fly and not sure if I see crane flies in my house or mosquitos now. And do crane flies bite?

- Really easy: A crane fly has no long piercing mouthpart: they feed mainly on nectar Female mosquitos have long piercing mouthparts, males are smaller and have shorter mouthparts for sucking nectar from flowers. Common crane flies are almost always bigger than a mosquitos.

- Q:I have this assignment to find out how a climbing crane is able to move up the building as construction continues.

- They add extra stages from the bottom. A tower crane is erected from a boom assembly, first and second tower sections of different cross section, and a base in a sequence of steps in which the boom assembly is mounted on a hollow climbing section dimensioned to be received in each of the larger second tower sections and defining a cavity dimensioned to receive each of the first tower sections. One of the latter is secured on a base in upright position, and the upright section is received in the cavity of the climbing section which is then raised relative to the first section and enveloped by one of the second sections. The enveloping section is secured to the base and the raised climbing section for supporting the climbing section whereupon the first tower section may be released from the base, raised, and secured to the second tower section. The climbing section may then be raised relative to the first tower section to permit the installation of another second section, and the procedure repeated, until all second or larger tower sections are superimposed on each other, the one first section being ultimately attached to the topmost second section. When the climbing section is raised relative to the attached first section, another first section may be superimposed on the one first section and the procedure repeated until the slimmer portion of the tower is assembled from superimposed first sections. Ultimately, the boom assembly is attached to the topmost first tower section, and the climbing section may be removed or stored for further use on the wider, lower tower portion.

- Q:don't its wheel provide the same amount of friction?

- the capacity of a travelling crane relates to its resistance to tipping, and is dependent upon wheelbase, which can be extended by use of the outriggers, and counterweight (the big boxy thing at the back of the crane). Every lift requires a firm and stable platform which is what the outriggers provide. For every lift (weight) and reach (how far from the slew point), there is a limiting capacity factor. This is required to be posted within the operator's cab. The actual load lifted may be monitored by a load cell on a running rope (or other location), and through a computer control, limit the actual capacity of the crane.

- Q:Or what style? ?

- I okorder / Gung Gee Fook Kuen: Taming The Tiger Fu Hok Sueng Ying Kuen: Tiger and Crane Double Form Tiet Sin Kuen: The Iron Thread

- Q:so yeah i know that cranes do the main work but i guess there are no such really toll cranes to do that with skyscrapers ?

- The cranes hook to the side of the building and climb the steel frame as it is being built. The crane can only reach a few stories so it has to climb each story's steel frame as it is finished.

- Q:Hello,I live in the St. Louis area of Missouri and during the summer, Crane Flies (I call them Mosquito Eaters) fly around all the time at night. I believe that it is normal for this type of bug to be nocturnal, but lately, I've seen them flying around, jumping around, and getting in the house DURING THE DAYTIME!! (AHH!!) :0 Is there any explanation for this? If so, is there anyway to reduce their population in and around my house? Thanks for reading.Ty

- Crane flies will probably be interested in the sunshine of the condo, so decreasing the light subsequent to the structure and what escapes from the home windows can help. They come from floor so it is rough to really do whatever to manipulate them.

- Q:The special equipment specified by the state is a periodical inspection cycle, wherein the crane is carried out every many years

- (two) small light lifting equipment, bridge crane, gantry crane, gantry crane, cable crane, crane mast, railway crane, jib crane, mechanical parking equipment every 2 years 1 times, the crane annual molten metal and hot metal 1.The rated load test, static load test and dynamic load test shall be carried out in the first test and the first periodic inspection, and the rated load test shall be carried out 1 times after each of the 1 inspection periods.The inspection process, the existence of major risks of hoisting machinery (such as special work environment, frequent accidents, etc.), inspection agencies approved by the provincial quality technical supervision department agree, can be appropriate to shorten the regular inspection period, but the short period of not less than 6 months.

- Q:where can i buy a cheap plush crane machine?

- Supplier of plush animals for skill crane and claw machines everywhere

- Q:I have a vessel 40 feet off the ground in a platform, and the crane can get to within 30 feet of it (from the side). I'm more curious of the process for sizing them though.

- All cranes have a lifting capacity that is based on the angle of the boom. The more vertical the boom, the more it can lift. With that in mind you select a crane based on the amount of weight being lifted and the angle the boom will have to have to reach the load. In some cases extra counter weights can be added to some crane to increase their lifting capacity. You should be using a contractor to supply the crane and the knowledge to provide the proper equipment and do the actual work safely.

- Q:please help me solve.. i really don't get itttt

- 1 horse power = 746 watt. So the work W done by the crane in 15 s is given by W = 8*746*15 J . So the distance, S through which the crane lifted 100 kg, presumably at constant speed is given by 100*9.81*S = 8*746*15 or S = [(8*746*15)/(100*9.81)] = 91.25 m

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

TOWER CRANE PT7023 with safety monitoring control system

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords