Factory supply decorative aluminum ceiling tiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

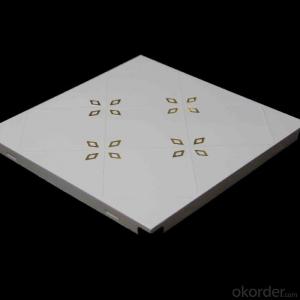

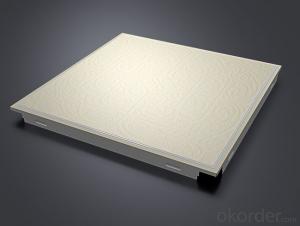

1) Our clip in aluminum ceiling:

Clip in square ceiling, widest applicable among all type of ceiling with outstanding advantages. Plain or pattern can be selected according to the actual requirement. Clip in system which is concealed, steady structure, flat surface, could be both used as ceiling and wall panel.

2) Specifications:

| Ceiling Type | Size(mm) | Height(mm) | Thickness(mm) | Edge Type |

| Clip In Ceiling | 300*300 | 18/20 | 0.45~0.56 | Beveled Edge/Square Edge |

| 600*600 | 20/24/28 | 0.45~0.7 | Beveled Edge/Square Edge | |

| 800*800 | 20/24/28 | 1.0 | Beveled Edge/Square Edge | |

| 300*1200 | 20/24/28 | 0.75~0.9 | Beveled Edge/Square Edge | |

| 600*1200 | 20/24/28 | 0.75~1.1 | Beveled Edge/Square Edge | |

| Lay In Ceiling | 275*275 (295*295) | 8 | 0.60~0.70 | Square Edge |

| 575*575 (595*595) | 8/12/18 | 0.60~0.70 | Beveled Edge/Square Edge | |

| 585*585 (595*595) | 10 | 0.60~0.70 | Square Edge | |

| 585*585(605*605) | 10 | 0.60~0.70 | Square Edge | |

| 595*1195*575*1175 | 8 | 0.60~0.70 | Square Edge | |

| 603*1210*585*1195 | 8 | 0.60~0.70 | Square Edge | |

| Ceiling Type | Open size(mm) | Width & Height(mm) | Thickness(mm) | Length(mm) |

| Open Cell Ceiling | 50*50 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 |

| 75*75 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

| 100*100 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

| 125*125 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

| 150*150 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

| 200*200 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

| Ceiling Type | Width(mm) | Length(mm) | Thickness(mm) | Edge Type |

| C-strip | C100/C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

| S-strip | C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

| H-strip | C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

| G-strip | C100 | 1000~6000 | 0.45~0.85 | Square Edge |

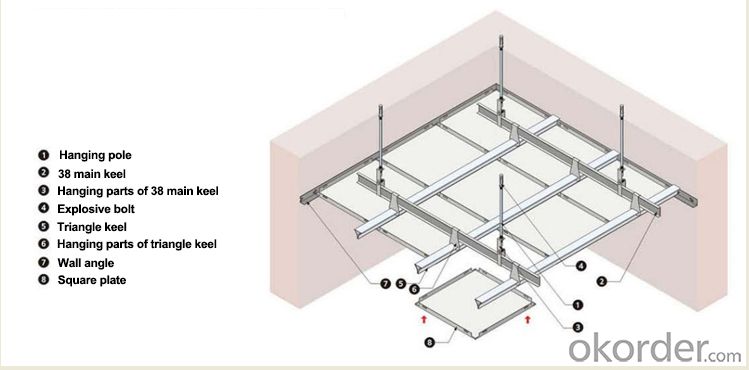

3.Installaiton & Accessories.

*Clip-In Panels are constructed of recycled aluminum

*Springs and clips are constructed of high performance steel

*Clip-In Panels integrate into and conceal 15/16” face HD/ID suspension grid

*Clip-In Panels for use in interior application

*Square edge design

*Standard sizes of 24” x 24”, 24” x 48” or custom size

*Clip-In Panels available in solid or perforated designs

*Clip-in placement allows for downward accessibility without special tools

*Easily incorporates air, fire, audio and other services

*Panels contain no organic compounds that support mold or microbial growth

*Factory applied, no-VOC powder coated paints and laminated finishes

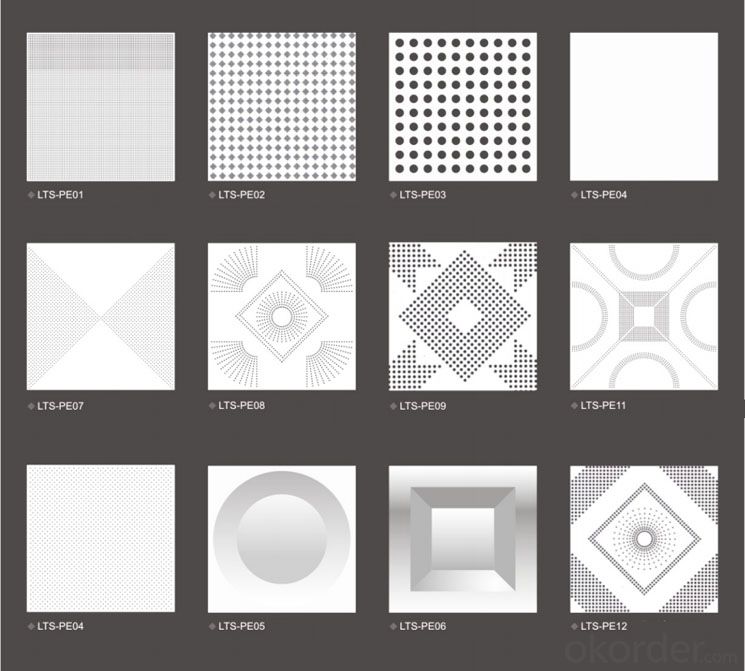

3) perforated pattern:

Perforation is a kind of processing technology for metal ceiling.Ceiling design beautiful patterns according to the arrangement of perforated holes with powerful sound absorbing and isolating effect. Rators possesses over 40 kinds of fixed perforated types, and could be customized according to client's requirements on patterns, sound absorbing to meet the actual situation.

4)Our Packing:

5)Installation Method:

The upper main keel and lower triangle keel are tightly connected with "cross" structure,therefore,it can assure the levelness of whole suspended system with more solid structure.

6)Sample Project:

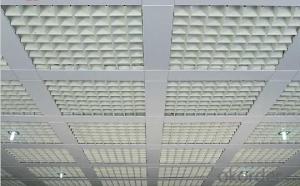

7)Application:

mainly used in project for big area with soundproof requirements, such as hotels,stores,office building, hospitals,railway stations,metro stations and so on.

8)Certificate:

ISO9001:2008, BV,TUV, Product Quality Certificate.

9)Factory Tour:

- Q:Lycra board ceiling price 60 square about how much money you need

- Aluminum plate commonly used specifications: ??? Common specifications are 300x300mm, 300x600mm, 400x400mm, 500x500mm, 600x600mm, 600x1200mm, 300x1200mm. How much money a square, probably in the 50-200 yuan / square. Mainly according to their choice of brand and quality is different, the price difference.

- Q:What is the depth of the hole in the ceiling to the ceiling?

- Aluminum plate hanging ceiling installation process seven basic steps: 1, elastic line 2, install the main keel 3, boom 4, the installation of the main dragon 5, the installation of sub-keel 6, the installation side of the aluminum 7, the installation of aluminum plate 8, installation of lamps and vents

- Q:Metal ceilings, including aluminum slabs and so on

- Ceiling ceiling is mainly used for airports, railway stations, office buildings, shopping malls, subway stations and residential and other places. The market has gypsum board, mineral wool board, PVC, aluminum slab plate and soft ceilings and so on. ?? The first generation of products for the gypsum board, mineral wool board; ?? Second generation of PVC; ?? The third generation is metal ceilings.

- Q:Mirror aluminum plate and nano-aluminum plate which is good

- One is to see what you want to hang in the location

- Q:600 × 600 aluminum slab plate production equipment how much money

- 600 × 600 of the project with the board, sub-machine and mold, the machine more than 30,000, more than 30,000 mold

- Q:600 * 600; 300 * 300; 300 * 600 specifications of the price of aluminum plate how much?

- Aluminum plate is made of aluminum alloy plate, through the open material, shear angle, molded, aluminum plate surface using a variety of different coating processing to get a variety of aluminum plate products, aluminum slab plate, the most important two Type, one is home improvement integrated Lvkou Ban, the other is the engineering Lvkou Ban, home-made aluminum slab board mainly to roll and frost the main series of two, with the development of home improvement integrated aluminum plate has been Variety of different processing technology are used to them, such as thermal transfer, glazed, ink printing, mirror, 3D and so on series is the most popular in recent years, home improvement integrated aluminum slab plate, home improvement integrated aluminum plate is Board surface fancy, service life, board advantage and so on to obtain market recognition, engineering aluminum slab board is commonly used roller coating, powder coating, film, scrub and other surface coating, the surface is relatively simple, the color is solid , Of which milky white is the most expensive to use aluminum slab plate, engineering aluminum plate to buy the most important depends on the coating, coating color protection is the primary consideration, the coating to maximize the life to ensure that the owners interest.

- Q:How to make the kitchen ceiling

- Aluminum buckle board paint, is possible. The key is to see what the paint, the knowledge is very deep, the average buyer is difficult to distinguish. Chinese people's high imitation ability is the strongest. The key lies in the quality of the paint equipment and its own paint

- Q:Bathroom and kitchen how to choose aluminum buckle ceiling?

- Kitchen ceiling to choose flat type ?????????? First, the choice of color can be more, make their own kitchen has a different kind of charm, give yourself a good mood; the second is a good clean, this is the most important. Kitchen, the inevitable fumes will be a lot, even if you cook the number of less, one or two years later will be clearly found the color of the kitchen a lot of bleak. When you want to clean, the ceiling is a very important part, almost 70 to 80% of the fumes on the ceiling.

- Q:Including: hook, triangular keel connection, nut, big hanging, income side, triangular keel, expansion screw, screw, the main keel (light steel keel) Should have 35 square meters, how much you need, the best price it!

- Add is 300 * 300 aluminum buckle board 1 square ratio: Board: 11 blocks Triangle keel: 1 Triangle keel hanging pieces: 3 Triangle keel interface: 1 50 Fu Long: 1 meter Main hanging: 3 Hexagon screw: 3 pcs Nuts 4 Corner: 4 meters Top burst one Steel row nails 1 box 1 piece of glass glue

- Q:Buy aluminum plate, need to pay attention to what

- Cabinet, Wei ceiling material is mainly aluminum plate and PVC, plastic steel or a strict PVC, but thicker some, essentially no difference, the aging of plastic things is inevitable, in the health of this humidity, Where the temperature is high or the aluminum plate is better. Decoration teams are generally recommended PVC, the real reason is the installation of trouble with aluminum gusset plate, they said that all the shortcomings of aluminum plate, often fabricated out. PVC ceiling is made of PVC, the material is very light, poor oxidation resistance, no moisture, no fire, easy to deformation, discoloration. At present in the big city PVC has been listed as out of products. With the improvement of the quality requirements of the decoration, and now home decoration has been basically used to do ceiling plate ceiling. Aluminum plate can be fire, moisture, anti-static, sound-absorbing sound insulation, and beautiful and practical, so it is most suitable for the use of more water and kitchen.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Factory supply decorative aluminum ceiling tiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords