Factory Galvanized Wire Galvanized Iron Wire Binding Wire 0.13mm to 4.0mm 0.2kg to 500kg/Roll

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Factory Galvanized Wire Galvanized Iron Wire Binding Wire 0.13mm to 4.0mm 0.2kg to 500kg/Roll Description:

Galvanized Iron Wire has the characteristics of thick zinc coating, good corrosion resistance, firm zinc coating, etc.

Galvanized Iron Wire mainly used in construction, express way fencing, binding of flowers and wire mesh weaving. Galvanized iron wire according to manufacturing technique, it includes hot-dipped galvanized iron wire and electro galvanized iron wire. Mainly telecommunication equipment and materials, medical equipment and device, weaving of wire mesh, steel rope, and filtration mesh, high-pressure pipe, construction, arts and crafts.

2.Main Features of Galvanized Iron Wire:

• Use widely

• Corrosion- resistant

• Durable

• Practical use

• Beauty Surface

• Versatile

3. Galvanized Iron Wire Images

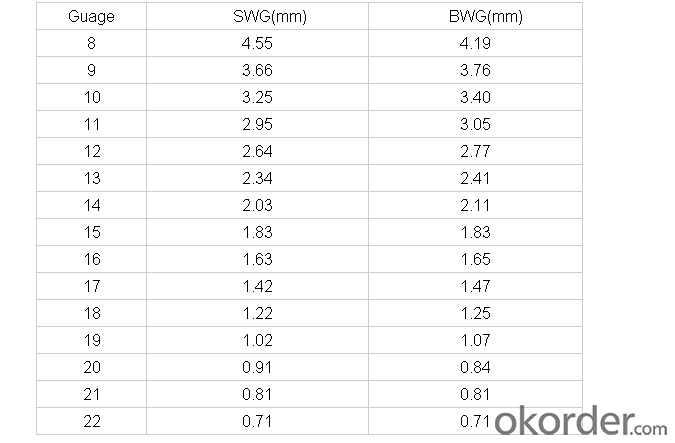

4.Galvanized Iron Wire Specification

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your products?

One of the most biggest manufacturer & supplier of wires and wire mesh,is a large-scale professional Galvanized Iron Wire factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world. Different kinds of wires and mesh are available according to customer’s requirements.

②What is your Technical Information of Galvanized Wire?

1).Material: super carbon steel

2).Processing by drawing, hot-dip zinc-plating

3).Standard wire gauge from 8# to 24#

4).Thick zinc-coating layer

5).Super in corrosion resistance

6).Firm coating layer

7).Custom size available

③How long can we receive the product after payment?

In the purchase of Galvanized Iron Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q:im installing a JVC raido in my 1990 nissan maxima and cant figure out how to properly conect the wires

- The easiest way to install the head unit is to buy the harness adapter that's for your car and match the colors of the harness adapter to the head unit wiring harness. An antenna adapter will also be needed for the new head unit. A dash kit will obvious will be needed to make the installation seamless.

- Q:friend i want litz wire in this wire consits of group of enamled coted copper wire(like machine winding wire with multi lead wire),so i want types different guages(that each lead in wiretotal wire guage) and no of leadds.my pupose is for project wire for with standing wire capcity of 20amp's. please give information............................

- www.okorder /

- Q:I am wiring a GFCI receptacle with two regular receptacles after it.So before the GFCI I have my 12/2 wire from where it will hook into the box (the line side), after it I have my wire going to the two other receptacles (the load side).Well the GFCI receptacle has screw terminals for the line HOT and WHITE wires as well as a GROUND. On the bottom it has screw terminals for the load side but ONLY the HOT and WHITE, no ground screw.Does this mean that I don't hook up the ground for the load wire or does it mean I have to pigtail the ground to the same screw the line ground is using?I didn't want to assume that I connect the line and load grounds out of fear I was circumventing the GFCI.

- i have an older home with metal boxes, so i attach the line ground to the ground screw in the box approximately in the middle of that wire. then i use the remainder of the wire as a pigtail and attach all of the remaining ground wires to the tail of that wire, plus a pig tail lead to the gfci outlet's ground terminal. if you have plastic boxes, you would skip the grounding of the box, and just join them all together, plus the lead for the outlets ground screw. you may find a picture of this in the instructions that came with the outlet, although they usually are kind of small and hard to read. good luck, hope this helped.

- Q:I am wiring a sony xplod amp up in my car and need to know what the skinny blue wire goes to. Any help would be appreciated.

- Run a fused (1 amp, 14 AWG) wire from a fuse in the fuse panel that only has power when the car is ON to one side of a switch. From the other side of the switch run the same sized wire to the REM (remote) connection on the amp. This allows for full control and you never have to worry about forgetting to turn off the amp. The switch is so you can turn off the amp at will so as not to give grandma a heart attack in the car. You can find fuse taps and in-line fuse holders at any autoparts store.

- Q:if a wire of initial length, and radius has a measured resistance of 1.0 ohms. the wire is drawn under tensile stress to a new uniform radius of 0.25r. what is the new resistance of the wire?

- assume the volume of the wire is constant cross sectional area = pi*R^2 A1 = PI * r^2 A2= PI * (.25*r)^2 = PI * .0625*(r)^2 = 16* A2 If volume stays constant, Length2 = 16* Length1 since resistance is proportional to length/area R2/R1= L2L1*A1/A2=16*16 = 256 The resistance now 256 times as great

- Q:But when I look closely (you can't see it in the picture unfortunately) there are some tiny wisps of the coiled copper wire that looks as if it could have been connected to the pulled wire. I'm not sure.How do I connect the wires to make the headsets work again?If you guys need more pictures, please tell me.Thanks in advance!

- If the twine is broken (open-circuit), rewiring it would artwork. the wonderful thank you to rewire it would be to strip the wires and solder them back at the same time. i might additionally attempt to untwist the twine as much as conceivable till now attempting this. in case you do not have get entry to the soldering kit, attempt twisting the wires back at the same time tightly and wrapping with electric tape. in case you ought to do it this style, it is going to probable no longer postpone for extremely long. reliable success!

- Q:Which is live and which is not, there is a black wire and a blue wire?

- That's it? A black wire and a blue wire? Hmm...I'd say that they are both hot if you have 240V single phase power. If it's multiphasic, they could be either delta to delta or delta to center tap. Didn't it come with a cord to plug it in? You are also overlooking a bonding screw used for grounding. Look for it, hook it up too. Tell us what the back plate says. (voltage, phases, watts, etc.)

- Q:is it safe to use twist on wire connector to connect my new stereo or should i crimp instead?

- I would suppose in this case there is a good better best way to do it. IMO I would never do twists on a stereo, at the very least, do butt connectors. Best way would be to solder each wire one by one and seal with heat shrink. That will give you a very clean look and you'll be proud of yourself :)

- Q:Am I able to do this? The wire burn the clay?

- if you're using a clay like the 3 main Sculpeys (original Sculpey, SuperSculpey, and Sculpey III), you will especially want to use wire inside them (or use other kinds of armatures) in any thin or projecting areas since those lines of polymer clay are brittle after curing in those kinds of areas

- Q:I have a carrier thermostat with red, green, yellow, white and blue wires. Bought a new honeywell, omly has red, green, yellow and white terminals. What do I do with the blue wire. Right now it is connected to rc with no jumper, but nothing works.

- This is an educated guess, even though we don't know how the furnace is wired. In many cases, the blue wire is used for C (common). Tape off or snip off the end of the blue wire and don't use it. Put the red wire on the RC terminal. Jump RC to R or RH if you have heat. Connect the other wires to their corresponding terminals. If blue is common, there's a good chance you blew the fuse on the control board (if your air handler has one) and/or you fried the transformer. That is, if you tried turning on the A/C.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Factory Galvanized Wire Galvanized Iron Wire Binding Wire 0.13mm to 4.0mm 0.2kg to 500kg/Roll

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords