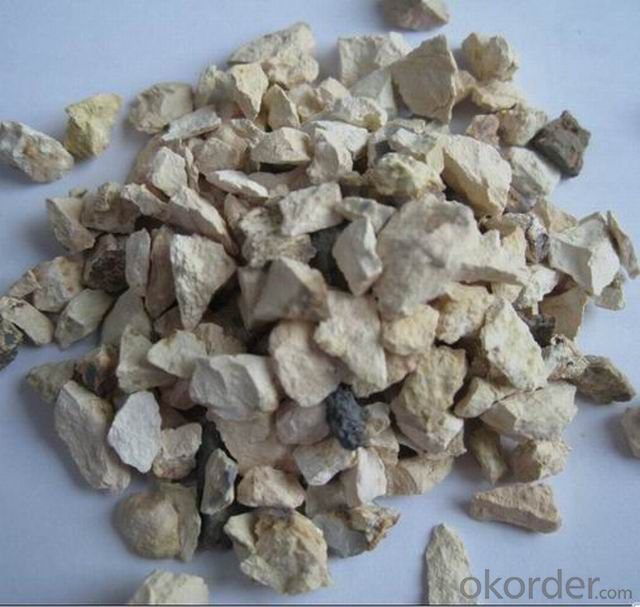

Factory Direct Supply Rotary Calcined Bauxite

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | ≤0.2 | Al2O3 Content (%): | ≥99 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° |

| Model Number: | TY-AKZ-99 | Brand Name: | CN | Size: | Any size |

Packaging & Delivery

| Packaging Details: | Wooden pallet and then polyethylene film is placed over it, finally the package is tied up with strips |

| Delivery Detail: | 2 months |

Specifications

Applications:

1.Lining of high temperature furnace

2.Thermal insulate of ultra-high temperature furnace

Physical and chemical index

Item | AKZ-85 | AKZ-90 | AKZ-99 | |

Chemical composition | Al2O3 | ≥85 | ≥90 | ≥99 |

SiO2 | ≤13 | ≤8 | ≤0.2 | |

Fe2O3 | ≤0.5 | ≤0.5 | ≤0.5 | |

Apparent Porosity% | 58-62 | 58-62 | 58-62 | |

Bulk Density g/cm3 | 1.4-1.7 | 1.4-1.7 | 1.4-1.7 | |

Cold Crushing Strength Mpa | ≥12 | ≥10 | ≥9 | |

0.1Mpa Refractoriness Under Load T0.6 °C | ≥1650 | ≥1700 | ≥1700 | |

Permanent Linear Change On Reheating (%)1500°CX2h | ±0.3 | ±0.3 | ±0.3 | |

20-1300°C Thermal Expansion % (x 10-6) | 0-7.8 | 0-8.0 | 0-8.6 | |

Thermal Conductivity(Average 800°C) W/(M.K) | ≤0.8 | ≤1.3 | ≤1.5 | |

Max Service Temperature °C | 1680 | 1700 | 1800 | |

- Q:Is the refractory reached British BS standard and used for cables in China at present ceramic silicone rubber?

- The texture should be designed according to the British relevant BS standard; crosslinked polyethylene or ethylene propylene rubber under 6600V to 19000 / 33000V is not necessarily ceramic silicone. The rated voltages of a small amount of smoke and corrosive gases from 3800 & # 47 when the BS 7835-2000 is affected by fire.

- Q:How to do environmental impact assessment for refractory Co., Ltd.

- Give you a list of data, you can refer to. List of required data for environmental impact assessment 1) name, type, specification and quantity of main process equipment. 2) the supply and consumption of raw and auxiliary materials (annual consumption and unit consumption of raw materials, ingredients, electricity, new water and recycled water). 3) public utilities: power supply system: need to build several substations? What is the size of the substation? Water supply system: fresh water consumption, circulating cooling water consumption, domestic water consumption, production water consumption, fire water consumption, respectively, how much? Heating system: if the project has a self heating system, the size of heating boilers, types, scale, fuel types, sources, annual consumption, the boiler's circulating water supply.

- Q:Does hardware construction materials contain refractory?

- refractory includes one kind of building materials. It is a special material and not commonly used.

- Q:Who can introduce the difference between galvanized fireproof?coatings and steel structure fireproof materials?

- There is no difference between them because they are the coating with the same texture. But generally galvanized treatment is not necessarily needed for brushing fireproof coating. Fireproof coating and galvanized surface have relatively poor bond strength. So it is advisable to bursh trasitional lacquer or micaceous iron on galvanized surface.

- Q:How to deiron refractory?

- Deironing refractory can take physical methods into consideration, such as magnetic?separation, reselection, etc. And it can also take chemical methods, such as flotation.

- Q:How much is the duration of fire resistance of the porous brick shale?

- It depends on its formula since the highest temperature varies from formula. For example, the temperature of common bricks is 900℃, if the lime in it accounts for most part, then the temperature could reach 1050℃; if coal ash accounts for over 40%--50%, then the temperature could amount 1050℃--1150℃.

- Q:What kind of refractory materials can withstand 1500℃ when processing briquette stove core and meanwhile cost less?

- Alkali resistant castables cost the least.

- Q:How to make fire resistant materials for building stoves

- Grand Theft Auto Vice City plus life code is what?

- Q:The classification of fire-resistant material

- Refractory material cna be divided into common and special fire proofing material. Common fire proofing material can be sub-divided in to acid fire proofing material, neutral fire proofing material. and alkaline fire proofing material according to chemical properties. Special fire proofing material can be divided into high temperature oxide refractory, refractory compounds and high temperature composite materials according to the composition. In addition, it also can be divided into common refractory products (1580 ~ 1770 ℃), high-grade refractory products (1770 ~ 1770 ℃) and super refractory products (above 2000 ℃) according to the strength . According to the shape, it can be divided into block (standard brick, special-shaped brick, etc.), special shape (crucible, sagger, pipe, etc.), fibrous (aluminum silicate, zirconia and boron carbide, etc.) and irregular shape (refractory clay, refractory castable, ramming material and so on). According to sintering process, it can be divided into sintered product, fused cast product and melting jetting product.

- Q:What do RH and DH stand for in refractories?

- DH :For human intelligence (diameter, board of directors). )

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Factory Direct Supply Rotary Calcined Bauxite

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords