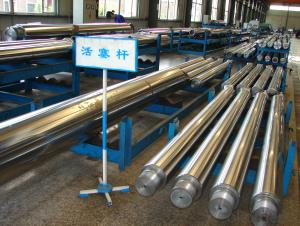

Factory Direct Custom Made Double Acting Hydraulic Ram Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q:The surface of the hydraulic rod is chromium, and it often causes strain, scratch, electric shock and so on. The routine method is slow to repair and the effect is not satisfactory. Don't want to play with copper, also do not want to use cold, patch method, because of poor adhesion, never long broken. Is there a better way to fix it?

- Although there are many kinds of electroplating, there are two main types that can be used for repair, namely, low temperature iron plating and thick chromium plating. Because the deposition rate is slow and the production efficiency is low, people often use the low temperature iron plating technology. In order to improve the corrosion resistance and wear resistance of the iron coating, the surface of the iron coating is usually plated with a thin layer of chromium.

- Q:Urgent, how, on the mechanical hydraulic buffer for a large amount? What mechanical pneumatic elements are used?

- The question is too general.Look for the same industry, large enterprises, in their website will be classified according to industry applications, check will be more convincing.

- Q:What is the cold drawn cylinder of a hydraulic cylinder? How about his quality? Master, help! Thank you

- What do you do with it, if it is hydraulic cylinder, then we usually use cold drawn seamless tube here

- Q:What is the pivot shaft in the cylinder?

- Suitable for welding of tool and mould, high-speed tool steel, hot work tool steel, steel, cast steel, T-1 steel, Nai Zhengang, vanadium steel, spring steel, martensitic stainless steel, austenitic stainless steel, ferritic stainless steel, and the unknown as well as between the various different types of steel welding etc.. Such as high pressure valves, broken bolt clearance, shaft transformation, etc., the effect is very satisfactory.

- Q:What is the basic working principle of the cushion device in the hydraulic cylinder?

- such as cylinder movement to the stroke switch, switch signal, cut or limit the flow of hydraulic oil into the cylinder, the cylinder movement slowed down, and ultimately by the buffer cylinder buffer. I hope to help you!

- Q:What does hydraulic cylinder type "HSG 80/60-1100" mean?

- The complete specifications are as follows:HSG* cylinder head linkage mode -D/d* pressure level - mounting mode * piston rod mounting mode * with buffer * oil port connection type * stroke * mounting distance

- Q:press the stroke 3CM, and then use the shearing machine as nitrogen cylinder return stroke, and then press down again 3CM.Consult you, 300 tons of hydraulic cylinder pressure, 28 MPa downward pressure stroke 3CM, and then use a shear plate as nitrogen cylinder return, and then press down again 3CM. 40 times per minute, OK? Is it feasible to do so?I would like to refer to the principle of shearing machine, to do a 3CM stroke 300 tons hydraulic press. Is that feasible? Since I need a very short stroke, I would like to use an ordinary larger cylinder instead of a fast cylinder. The return trip would also like to use nitrogen, which would make the hydraulic part the simplest, not knowing whether I was right or not

- Both pendulum shearing machine and gate shearing machine adopt single acting hydraulic cylinder! Jianhu Huabo hydraulic guillotine shears is accumulator return

- Q:We have to design a manual plunger water hydraulic pump, but the wall thickness of the cylinder will not be designed and checked. I follow the sigma delta is not less than PD/2[design is out of 10mm thick, but the teacher said 5mm can withstand the pressure of 150MPa, the material with corrosion resistant stainless steel can. Some of my parameters are the maximum cylinder pressure 140MPa, cylinder size d=18mm (can also be smaller), length 60 ~ 80mm, how can I design wall thickness? thank you very much indeed

- The maximum permissible bearing pressure in the thin-walled tube [P] formula: [P]] =2[sigma phi S (D / S) in the formula: [Sigma - material allowable stress; coefficient of weld - diameter, seamless tube, pipe wall thickness with =1; S-- d--; the inner diameter of the pipe.

- Q:What is it used for? What kind of factory is likely to be used in general?

- Hydraulic equipment, cylinders, cylinders are used in the principle of hydraulic transmission power, in particular, low aerodynamic pressure, hydraulic high. At the same time, the environment

- Q:What are the characteristics of a piston hydraulic cylinder? How many kinds are there? What are they used for?If anyone knows, just say something

- The hydraulic cylinder from the structure can be divided into the piston cylinder, piston cylinder and oscillating cylinder. The cylinder from the structure can be divided into the piston cylinder, pneumatic cylinder, telescopic cylinder hydraulic cylinder. The working principle is: as its principle I must first say 5 basic components, 1- and cylinder 2- cylinder piston and piston rod sealing device of 3- 4- buffer 5- exhaust device to work each cylinder is almost similar to the original, I took a manual jack is its original work, Jack is a simple cylinder. By manually pressurized straw (hydraulic manual pump) of the hydraulic the oil through a single valve into the cylinder, the hydraulic oil into the cylinder because the reasons for individual valve can not be returned back, forcing the cylinder rod upward, then work to continue to keep the hydraulic oil into the hydraulic cylinder continuously, thus increasing, hit when to drop Hydraulic valve, hydraulic oil back to tank. This is the most simple of the original work, others have improved on this basis, because of the time I would say the most simple principle. The advantages and disadvantages of the cylinder cylinder cylinder and the cylinder with almost I said the following 3 bit 1-- as the pneumatic system pressure is generally in the range of 0.2-1.0Mpa, so the cylinder is not bigger.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Factory Direct Custom Made Double Acting Hydraulic Ram Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products