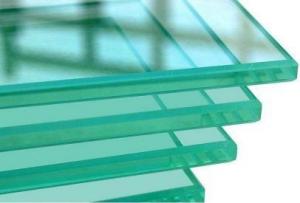

F Green Toughened glass8mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Provide QAIC/CN attestationProvide ISO 9001-2008 CCC attestation

Provide super quality and competitive price

Tempered, toughened glass is heated to the temperature that near soft point, the surface resulting from the rapid cooling homogeneity has powerful compressive stress, the glass is double increase in all mechanical performance indexes. The surface stress value for tempered glass is more than 90Mpa and 24-69Mpa for the semi-tempered or toughened glass.

The feature of tempered glass:

High intensity: The bending strength of tempered glass is 3-4 times than common glass and the shock strength is 6-7 times than common glass.

Heat stability: Tempered glass has good thermal stability can withstand a range in 300 ℃temperatures, which is 3 times than common glass.

Security: Because of the stress layer of tempered glass, thus has strong shock resistance, make its not easy to damage, and it will not cause greater harm to human body when the broken glass after obtuse angle formed by small particles.

Toughened glass is also called heat enhancement or tempered glass, its strength is 1.5 to 2 times of ordinary annealed glass, thermal stability is twice as common annealed glass, toughened glass of flatness is approach to ordinary annealed glass and far superior to toughened glass, its biggest advantage is that there is no explosive's ills, but once causing damage, it still produces larger pieces and after its damage easily hurt the body, but its security is better than ordinary annealed glass.

Maximum processing size: 11000 mm * 3000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 4 mm to 25 mm

Insulating Glazing

A. All glass can be processed before assembly

B. Glass transfer onto the glass loading machine

C. Edge coating removing of coated glass

D. Wash and clean strictly

E. Automatic bending for air spacer

F. Automatic molecular sieve filling

G. Automatic butyl rubber applying

H. Automatic framing

K. Automatic scanning positioning

L. Automatic double sealing

M. Transfer by sucking disc

N. Conner finishing

O. Glass on the shelves till solidification

P. Customized wooden cases according to the size of glass

Q. Transfer the glass into the specific wooden cases

R. Leading Time:10 days for an average area of 1000 square

meters tempered glass

S. Trade terms: FOB and CIF.

T. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

U. The container loading after the package checking

- Q:Will the frame glass curtain wall, each frame size 1615 * 965mm, the use of 6 PCT tempered glass is dangerous?

- According to the curtain wall in the coastal side, 1615 * 965mm specifications 6mm tempered glass stress calculated value is 31N / mm ^ 2, and its allowable value is 84N / mm ^ 2, the calculated deflection is 9mm, and its allowable value is short edge 1/60 (ie 965/60 = 16mm). So it is safe enough. Glass shop that glass is too thin, I guess the reason: ah: they give you the glass is not steel, Oh, so pay attention.

- Q:So it will look like the ferris bueller ferrari. If so how can that be done.

- Anything is possible when your talking about fiberglass and making kit car bodies. You have to have wood working tools - and auto tools - Among other things you will have to know the fiberglass methods And how to mix it right - dealing with 1 gallon + at a time. Lastly you better be good with a tape measure and know angles and such.

- Q:What is the introduction of new glass advertising slogan

- New glass is your first choice

- Q:Why do you need 3C certification for tempered glass?

- Automobile safety glass and railway vehicles with safety glass certification mark printing method can be used printing method, screen printing, etching or sandblasting and other methods, signs should be clear. Safety-related building glass can be used for temporary signs, or it can be permanent, temporary signs can be removed after installation of the glass. For some buildings on the glass body should not use the permanent signs or temporary signs, should be approved by the National CCC Certification Center issued by the management center in its minimum packaging and accompanying documents (such as certificate) used.

- Q:In addition to the service industry, what other work?

- What will you do? Everyone has his own specialty

- Q:What are the advantages of building a house entirely made of glass?(Any Type Of Glass)

- You can see outside? lol i can think of lots of disadvantages... like all the smudges to clean && the house could break! haha idk sorry i couldnt help

- Q:In the kitchen glass lid heating process, it is necessary to remove the heated glass cover from the heating furnace and transfer it to the conveyor belt in the specified direction for subsequent process. Currently rely on manual operation, due to high temperature radiation production conditions are bad, there is no alternative to artificial approach?

- Features and functions: ??????? 1) run the game can be configured to run smoothly to avoid mechanical resonance. 2) accurate positioning, running a continuous impact of small mechanical. 3) Simple and reliable operation, maintenance-free. 4) During the transit process, there is a 180 degree flip process action to facilitate the next step to work. 5) The transit time is maintained for 3 to 6 seconds, which is conducive to improving product quality. 6) on the edge of the glass cover to protect, to avoid the defective.

- Q:Benjamin Franklin built the Glass (H)Armonica in 1762 I want to know what it was made of and how.

- because okorder

- Q:Not man-made destruction of tempered glass why suddenly broken

- Tempered glass has bleed characteristics This is because the glass raw materials containing nickel sulfide crystals, is the world's existing manufacturing technology can not be completely avoided, only through the purity of raw materials and processing technology to control the risk of a little lower blew. On the concept of self-blasting rate, our country only on the external walls of the engineering glass has a national standard, I do not know whether the foreign industry for the use of tempered glass also has detailed provisions. One ton of glass raw materials, there are at least 3-4 nickel sulfide crystals, this one ton of glass made of several square meters of the size of the glass, which will have 3-4 tablets blew, which is blew the image depicting.

- Q:can i build a tank 2000x500x400mm with braces with 5mm thick glass?

- theoretically okorder /... visit these sites where you can find the safety factor with 5 mm but really 5mm is a nothing thickness as your width is 20 inch which is too much pressure on side glass

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

F Green Toughened glass8mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ /month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords