Extruded PP Corrugated Sheet made of 100% virgin PP material

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

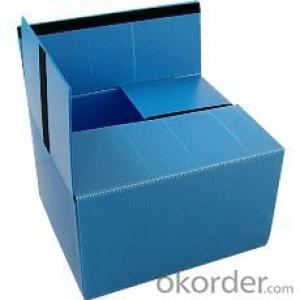

Extruded PP Corrugated Sheet is an extruded twin wall plastic sheet consisting of two flat walls connected by vertical ribs. Eco-friendly PP Plastic Hollow Sheet is mainly manufactured from a high impact co-polymer polypropylene (PP) or polyethylene (PE) resin, which can be recycling,washable,durable and reuseable etc.CMAX PP corrugated sheet, Plastic HollowSheets / Board / Signs has proved that it is suitable in the uses of packaging, advertising, construction, agriculture, industry and Pharmaceutical etc.

Specification:

1. Thickness: 2mm,3mm,4mm,5mm,6mm,7mm,8mm,10mm,12mm

2. Weight: From 250g/m2 to 3500g/m2

3. Standard Size: 2440mmx1220mm, 2000x1000mm, 1200x800mm, 1000x1000mm or as request

4. Grade:Corona Treated, Anti-Static, Conductive, UV Stabilized and Flame Retarded etc;

Feature:

PP corrugated sheet offers efficient solutions to a wide variety of applications. Compared to alternatives such as cardboard, metal or rigid plastic, Eco-friendly Twin Wall Corrugated Plastic Polypropylene PP Hollow Sheet offers the following unique advantages

1. Economical : both in use and purchase

2. Flexible : as a material and as application

3. Environmentally sound : recyclable

4. Water and moisture resistant

5. Approved for food packaging

6. Strong and durable

7. Lightweight

8. Good chemical resistance

9. Easy to print

- Q:What kind of wood is commonly used in wooden packing boxes?

- The frame wooden structure can be divided into class I (within the frame wooden box): frame member in the inner box board, suitable for general contents; class II (frame wooden box): frame structure in the outer box plate, applies in the length direction as a whole, and has sufficient rigidity to the contents. The basic provisions of its design consider the usual conditions of transportation, loading and unloading and storage.

- Q:What's the name of the material used in paper packing boxes?

- Honeycomb paperboard featuresThe honeycomb cardboard is made according to the principle of nature of the honeycomb structure, it is the connection of corrugated paper into numerous hollow three-dimensional hexagonal glue bonding method, form an overall stress - paper core, environmental protection and energy saving materials of a new type of sandwich structure and on the two sides of the adhesive paper. Honeycomb paperboard is mainly characterized by:(1) light quality, little material and low cost. Compared with other kinds of sheet structures, honeycomb sandwich structure has the largest strength / mass ratio, so its performance / price ratio is good, which is the key to the success of honeycomb paperboard.(2) high strength, smooth surface, not easy to deformation. Honeycomb sandwich structures are approximately isotropic, have good structural stability and are difficult to deform, and their outstanding compressive and flexural capacity are the most important characteristics required for box type packaging materials.(3) shock resistance and good cushioning. The honeycomb cardboard made of flexible paper core and made of paper, has good toughness and elasticity, honeycomb sandwich structure provides a unique buffer with excellent performance, with all the materials in the buffer unit volume of higher energy absorption value, high thickness of honeycomb paperboard can be EPS foam cushioning plastic pad has the extensive use of the alternative.(4) sound absorption and heat insulation. The interior of the honeycomb sandwich structure is a closed chamber filled with air, so the utility model has good sound insulation and heat insulation performance.(5) pollution-free, in line with the trend of modern environmental protection. The honeycomb paperboard is made entirely of recycled paper material and can be recycled and recycled in one hundred percent places after use.

- Q:How about a carpenter's packing case?

- First introduce the core board1, big core board is also called blockboard, is in the middle of the two pieces of wood veneer splicing board and clamp. The wood and wood veneers in the middle are made of adhesive glue, so the formaldehyde release of many large core boards is beyond standard.2, the purchase of large core board must buy regular manufacturers of E1 products.Choose to observe its appearance, see big core board surface is smooth, without warping, deformation, there is no bubble, depression, the best can be opened the article core observation internal is uniform and tidy, the smaller the gap, and should not have decayed, fracture, wormhole, knot etc..Buy Daxinban, businesses tend to have many piles of stacked Daixinban a picture, can choose new Duitou (ashLess, wood color new) put a few of its big core board up, fan about, smell the taste of the drift out, without stimulation, environmental protection is relatively good.

- Q:What are the requirements for product packaging?

- When the product quality in more than 50kg or packaging volume is above 1m3, must be in the corner of the box body file on the iron nail wrap angle for packaging end plate for the entire board and gratuitous file boxes, fiberboard box and power transmission control equipment, in the wooden box after sealing nail, must steel fastened around in wooden cases, wooden box at each end of a nail.From the date of shipment, under normal storage and transportation conditions, the protection period of the package is 1 years. In the meantime, the packaged product shall be intact.

- Q:Is it necessary to leave the packing cases for large household appliances?

- Best to stay for more than 7 days, because there is a problem is seven days replacement, replacement to the original box! Otherwise, do not change! Prescribed by the state! After the warranty is the manufacturer's problem! The manufacturer will engage in the houses!

- Q:Does the air conditioner packing box contain the connecting copper pipe and the outer machine bracket?

- Some, anyway, tens of dollars to pay, installation fees on the right, do not pay to buy other materials

- Q:Can the express company provide the computer's packing box?

- Some can, and some will not provide, specifically ask the courier company. It costs a lot of money to add a box... You'd better get the box to tell the truth, I suggest you host your own bag Kazakhstan is not too heavy that the flat display handled well, home for an LCD flat screen, or not good? Not expensive (second-hand) you ha go logistics account money, you have enough to buy a flat screen display.

- Q:Where do you use wood containers?

- Wood boxes can also be used in places where paper boxes are available, but where paper boxes are used, paper boxes may not be available. Wood packing box can impact more than paper packaging box, can load and compression, so expensive goods, fragile goods, require long-distance transport goods (especially to repeatedly Daoteng items) will choose the wooden packing box, a protective box in the article is not damaged is the objective choice of packaging cases.

- Q:What's the difference between wooden case packing and plywood packing?

- No, wooden cases packed in wooden cases should be fumigated or heat treated by IPPC. They will also be issued with relevant certificates (which are not used now). Plywood will not be used

- Q:What's the square of the packing box?

- The packing box is a cube, so you have to work out the area of its 6 sides. Plus the overlap of the upper and lower openings of the packing carton and an overlap area around it. You can see the carton fully unfolded.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Extruded PP Corrugated Sheet made of 100% virgin PP material

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products