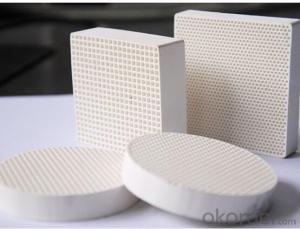

Extruded ceramic filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Extruded ceramic filter

Application: Grey iron, ductile iron, aluminum alloy and other non-ferrous alloys.

NINGXIN ECF filter can effectively remove inclusions and eliminate turbulence in the metal stream. Mullite-based ceramic material with a dense network of perfectly cells to withstand thermal shock and extreme pouring temperatures.The cellular design also provides an engineered balance between flow rate and strength.Our extruded ceramic filters have excellent properties of good thermal stability, high specific surface area and resistance to acid and alkali. They are applicable to wide and extensive foundry filtration applications and processes.

Product features:

-Decrease the impurity of molten metal

-Deduce the turbulence of molten metal

-Improve the castings mechanical properties

-Decrease machining cost and improve the cutting characteristics

-Improve casting quality and yield

Technique data:

Main material: Cordierite, Mullite.

Refractoriness: >1500℃

CSI (cells per square inch):100/200/300

Porosity(%): 35-60

Bulk Density(g/cm3): 0.8-1.2

Compression strength:>20MPa

Size:From 40mm to 150mm square, rectangle and round shape

Hole type: square, round, triangle

Common sizes:

37x37mm 43.5x43.5mm 49x49mm 55x55mm 66x66mm 81x81mm D50mm D55mm D66mm D70mm D81mm

37x37mm 43.5x43.5mm 49x49mm 55x55mm 66x66mm 81x81mm D50mm D55mm D66mm D70mm D81mm

Thickness:9.5mm 12.5mm 15mm

Advantages:

-High dimensional accuracy

-High strength,no broken or damaged in use and transport

-Higher filtration effectiveness than fabric or wire mesh filter

- Q:Beneficiation ceramic filter no problem, the technical parameters are normal, but filter out the concentrate water suddenly excessive, what is the reason?

- Beneficiation of ceramic filter, the technical parameters are normal, but the water will fill in groove is what reason

- Q:How can I avoid the backwash pressure in the production of ceramic filter?

- Recoil of the ceramic filter is on the clean water under certain pressure, from the inside out flushing blockage blockage in the ceramic filter plate on the internal pore water pressure, the recoil is generally less than 0.12MPa, the pressure is too small or no recoil recoil effect is not good.

- Q:Does the ceramic factory use hydrochloric acid?

- For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate. (do not recommend sulphuric acid)

- Q:The ultrasonic wave of ceramic filter is not good. What's going on?

- In ancient China, filtration technology was applied to produce paper made from plant fibers in 200 bc. The paper method was improved in AD 105. He wandered in dense in papermaking during plant fiber pulp fine bamboo. Water curtain gap filtration, a thin layer of wet pulp stay on the bamboo surface, after drying into paper.

- Q:What are the poor filtration effects of vacuum disc filters?

- Under normal circumstances, high vacuum, vacuum suction, high production capacity, filter cake moisture control is good. At present, some ceramic filters are equipped with two or multi-stage vacuum system to obtain almost absolute vacuum, and can reach 0.09 ~ 0.098MPa.

- Q:Can the plate filter press pass through the filter plate?

- There are many types of pumps to be used, such as screw pumps, slag pumps, rotary pumps, piston pumps, and diaphragm pumps.

- Q:How many degrees does the ceramic filter melt?

- Spinel is basically over 1600-1700. It's not too acid proof.There are other materials such as silicon nitride. Ceramics can be more than 1300 degrees in temperature. So the material you are using now is unlikely to melt and melt, and you can change it into one of the top materials. Baidu, this stuff is all over the street.

- Q:How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber board quality can be judged from the following aspects:1, appearance. The surface is flat and the cutting surface is well arranged, and vice versa.2 density. Press the hands, and the surface is soft and smooth.3, process. Vacuum suction and continuous production process.4, cross section, slag ball content is low.

- Q:Ceramic filter ceramic plate blockage, productivity reduction, how to clean, to achieve the best effect cleaning problems

- Selection of new ceramic filter plate:Because of the different size and characteristics of the pulp, different users need ceramic filter plates with different pore sizes (i.e., the average range of their surface pore size). In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q:Influence factors of ceramic filter

- On the other hand, as the spindle speed slows down, the thickness of the slurry is thickened, and the moisture of the concentrate is also affected. For viscous material, ceramic filter with ceramic plate to work as filter media, when the cake is formed gradually into the porous filter medium filter cake itself, and the cake is not easy to form a viscous material, forming a dry cake appearance does not slow, the spindle speed is easy to reduce the water content of concentrate. Similarly, the spindle speed is accelerated, the cake formation time in the vacuum zone is shortened, and the slurry thickness is reduced, and the material can be improved for the easy molding material. But the spindle speed is too fast to be cleaned after each cycle of the ceramic plate. As for the viscous material, the cake is difficult to form after the spindle speed increases, and it will affect the capacity. Therefore, the use of ceramic filter should focus on the inherent nature of the concentrate to explore the best spindle speed. Generally, the higher the temperature, the smaller the viscosity of the liquid, the more conducive to improve the filtration rate, reduce the cake or sediment water, while reducing the viscosity of the slurry, can improve the processing capacity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Extruded ceramic filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords