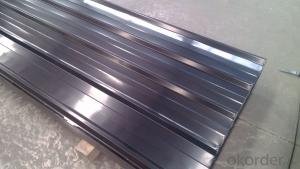

Extruded Aluminum Plate For Roofing Building Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Extruded Aluminum Plate For Roofing Building Application

Specifications

Alloy NO. | Thickness | Width | Length | Production line | Circulation size |

1050 1060 1100 3003 | 0.3-9.5mm | 800--2200mm | 1000--10000mm | DC,CC | 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm

|

5052 5083 5454 5754 5086 | 0.5-150mm | 800--2200mm | 1000--6000mm | DC | |

6061 | 5-150mm | 800--2200mm | 1000--10000mm | DC | |

7075 | 6-150mm | 800--2200mm | 1000--10000mm | DC | |

Packing | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | ||||

Application | decoration:ceilings,walls,furniture,cabinets,elevators,signs,name plate, transportation, cookware, household appliances:refrigerators,microwave ovens, machinery, mold making,aerospace and military aspects, auto, PP cap , construction etc | ||||

Standard | Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM | ||||

Mechanical Property: GB/T 3880.2-2012, JIS, EN, ASTM | |||||

MOQ | 5TONS | ||||

Kind attention | Specifications can be customized as the customer’s requirements | ||||

Application

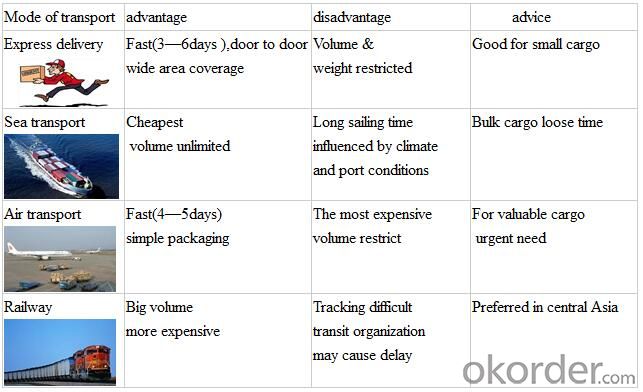

Shipment

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

- Q:Can aluminum sheets be bent without cracking?

- Indeed, aluminum sheets possess the remarkable quality of being bendable without succumbing to cracks. This is due to aluminum's exceptional malleability and ductility, enabling it to be effortlessly molded and reshaped without experiencing fractures. Nevertheless, the success of bending aluminum sheets without cracks hinges upon various factors, including the sheet's thickness, the type and grade of aluminum employed, and the particular bending method employed. To guarantee its integrity and prevent cracks, it is crucial to utilize appropriate tools and techniques when embarking upon the task of bending aluminum.

- Q:Are aluminum sheets suitable for soundproofing applications?

- Aluminum sheets are not typically suitable for soundproofing applications as they have low mass and do not effectively block or absorb sound waves.

- Q:What is the shear strength of 101 aluminum sheets?

- The shear strength of 101 aluminum sheets may differ based on different factors like sheet thickness, aluminum alloy composition, and manufacturing process employed. Typically, the shear strength of 101 aluminum sheets falls between 20,000 and 30,000 pounds per square inch (psi). Nevertheless, it should be emphasized that these values are approximate, and precise figures can vary. For precise information on the shear strength of 101 aluminum sheets, it is advisable to refer to the material's technical data sheet or contact the manufacturer directly.

- Q:Are the aluminum sheets suitable for aerospace applications?

- Yes, aluminum sheets are suitable for aerospace applications. Aluminum is widely used in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and high thermal conductivity. These properties make it an ideal material for manufacturing aircraft structures, such as fuselages, wings, and structural components. Additionally, aluminum can be easily machined and formed into complex shapes, allowing for the production of lightweight and aerodynamic structures. Furthermore, aluminum sheets can be easily joined using various techniques, including welding and riveting, ensuring the structural integrity of aerospace components. Overall, aluminum sheets are well-suited for aerospace applications and have been extensively utilized in the industry for many years.

- Q:What are the different methods of cutting aluminum sheets?

- To cut aluminum sheets, one can utilize various methods based on specific requirements and material thickness. Some commonly employed techniques include: 1. Shearing: By means of a shearing machine, straight lines can be cut in the aluminum sheet. The machine applies force to a blade, resulting in material separation. Shearing is a swift and efficient approach, especially suitable for thinner gauges. 2. Sawing: For cutting aluminum sheets, circular or bandsaws equipped with specialized metal-cutting blades are commonly employed. This method allows for greater precision and controlled cuts, making it ideal for thicker sheets. 3. Laser cutting: This highly precise and efficient technique employs a concentrated beam of light to melt and vaporize the aluminum, resulting in a clean and smooth cut. Laser cutting is particularly advantageous for intricate designs and complex shapes. 4. Waterjet cutting: This method involves the use of a high-pressure stream of water mixed with abrasive particles to cut through aluminum sheets. It is applicable to various thicknesses and allows for precise cuts without generating heat. Waterjet cutting is often preferred for thicker sheets or when high precision is required. 5. Plasma cutting: By employing a high-temperature plasma torch, aluminum sheets can be melted and cut. The torch generates an electric arc, ionizing the gas and creating a plasma state. Although versatile and capable of cutting through different thicknesses, plasma cutting may yield rougher edges in comparison to laser or waterjet cutting. When selecting the most suitable method for cutting aluminum sheets, it is crucial to consider project-specific requirements such as desired cut quality, speed, and complexity.

- Q:Are 101 aluminum sheets available in different finishes (e.g., brushed, polished)?

- There are different finishes available for 101 aluminum sheets, including brushed and polished. These finishes are obtained using various methods that create distinct textures and appearances on the surface of the sheets. To achieve a brushed finish, the sheet is brushed with an abrasive material, resulting in a pattern of fine lines. This finish is commonly used to give the sheet a matte look. On the other hand, a polished finish is achieved by polishing the sheet to create a high shine. This finish is often chosen to create a smooth and reflective surface. Therefore, depending on the desired aesthetic or functional requirements, one can opt for either a brushed or polished finish for 101 aluminum sheets.

- Q:What are the different methods of surface etching aluminum sheets?

- There are several different methods for surface etching aluminum sheets, each with its own advantages and specific applications. Some of the most common methods include chemical etching, laser etching, and mechanical etching. Chemical etching involves using a chemical solution to selectively remove the surface of the aluminum sheet. This method is highly precise and can achieve intricate designs or patterns. It is often used for decorative purposes, such as creating logos or artwork on aluminum signage or nameplates. Additionally, chemical etching can be used to create functional features, such as improving adhesion for paint or coatings. Laser etching, on the other hand, uses a high-powered laser to remove material from the surface of the aluminum sheet. This method is extremely precise and can create very fine details. It is commonly used for marking or engraving aluminum sheets, such as serial numbers, barcodes, or product identification. Laser etching is also a non-contact process, which means it does not cause any physical damage to the sheet. Mechanical etching, or abrasive blasting, involves using an abrasive material to physically remove the surface of the aluminum sheet. This method is typically used for larger-scale applications, such as creating a textured or matte finish on aluminum panels or sheets. Mechanical etching can also be used to remove any surface imperfections or contaminants, preparing the aluminum sheet for further processing or finishing. In summary, the different methods of surface etching aluminum sheets include chemical etching, laser etching, and mechanical etching. Each method offers unique advantages and is used for specific applications, ranging from decorative designs to functional markings or surface treatments.

- Q:Can the aluminum sheets be used for manufacturing heat sinks?

- Yes, aluminum sheets can be used for manufacturing heat sinks.

- Q:Are the aluminum sheets suitable for manufacturing food processing equipment?

- Yes, aluminum sheets are suitable for manufacturing food processing equipment. Aluminum is a highly versatile and durable material that is known for its corrosion resistance, lightweight nature, and ability to withstand high temperatures. These qualities make it ideal for use in the food processing industry, as it ensures the equipment is hygienic, easy to clean, and can withstand the demanding conditions of food production.

- Q:What are the different methods of cutting aluminum sheet?

- There are several methods of cutting aluminum sheet, each with its own advantages and applications. 1. Shearing: This is a straightforward method that involves using a sharp blade to cut through the aluminum sheet. It is a fast and efficient process, especially for straight cuts. However, it may not be suitable for complex or intricate designs. 2. Laser cutting: Laser cutting utilizes a high-powered laser beam to melt or vaporize the aluminum sheet, resulting in a precise and clean cut. This method is ideal for intricate designs, as it allows for detailed and accurate cuts. Laser cutting is also fast and can be automated, making it suitable for large-scale production. 3. Waterjet cutting: Waterjet cutting involves using a high-pressure stream of water mixed with abrasive materials to cut through the aluminum sheet. This method is versatile and can handle different materials and thicknesses. It produces a smooth and precise cut without generating heat, making it suitable for heat-sensitive materials. 4. Plasma cutting: Plasma cutting involves using a plasma torch to heat and melt the aluminum sheet, creating a cut. It is a fast and cost-effective method, especially for thicker sheets. However, the cut might not be as clean compared to laser or waterjet cutting. 5. CNC milling: Computer Numerical Control (CNC) milling involves using a rotating cutting tool to remove material from the aluminum sheet, creating a cut. This method is precise and can produce complex shapes and designs. It is commonly used for prototypes or small production runs. It is important to consider factors such as the desired cut quality, complexity of the design, material thickness, and production volume when choosing the appropriate method for cutting aluminum sheet.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Extruded Aluminum Plate For Roofing Building Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords