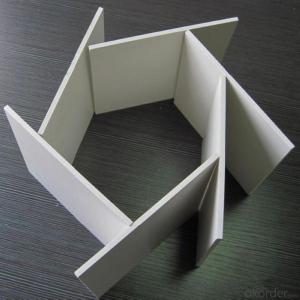

extrude PVC foam sheet in Plastic Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

1. Brief Introduction

There are two kinds of PVC Sheet: PVC Foam Sheet and PVC Rigid sheet, and each of them could be cataloged by different producing processes.

They could be used in furniture making such as bathroom and kitchen cabinet or wall cladding , advertising field such as sign board, printing board, indusry field such as the cushion for the heavy machine, etc.

2. Application

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

3. PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

4.FAQ

1. If the products have some quality problem ,how will you deal with it?

Answer : If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

2. Could you provide samples?

Answer : Yes, We provide free samples for customers, but customer shall bear the freight charges or negotiate about this.

5.pictures

- Q:Cabinet door environmental protection grade how to divide

- Cabinet door of the substrate if it is a density board, then its highest environmental rating is E1 level, and like the double-sided surface of this substrate is the particle board can reach the highest standards of Japan JIS four standard environmental standards

- Q:Ecological wood plate prices

- Ecological wood panels are mainly ecological wood plank, ecological wood sound-absorbing panels, ecological wood small round panels, ecological wood panels, etc., the price varies according to product models are different, and the indoor with the price of outdoor ecological wood is not the same , The specific can understand the Riling ecological wood

- Q:Is there a sheet with a flame retardant function?

- The market should still have a lot of, after all, now everyone's security awareness are put up. Before the concern of the wood industry's fire-retardant board seems to be doing this, you can see.

- Q:Because the family has children, do not worry ah ~ ~ ah! Is it possible to detect it?

- Whether the furniture is environmentally friendly is to see the amount of formaldehyde release if the house of the big taste, then you buy some plants placed at home diligent windows

- Q:I am in Changsha, saw my music cabinet, saying that their cabinet is the European E0 level is true?

- E1, E0-class plate, mainly refers to the finished sheet containing the amount of formaldehyde content. At present, the market use of the board environmental protection level mainly E2, E1, E0 level, which E0 level for the most advanced, the highest environmental index, with the least amount of formaldehyde, ≤ 0.5mg / L (belonging to the world's top standard); followed by E1 , ≤ 1.5mg / L (in line with European standards); E2 level ≤ 5.0mg / L (in line with domestic standards). In general, the average amount of formaldehyde emission is less than 0.5mg / L of the material belongs to the E0 standard, the average formaldehyde emission is less than 1.5mg / L of the material belongs to the E1 standard. The formaldehyde emission level is less than 0.5mg / The Now the domestic custom wardrobe in the very few E0-class plate, such as the top of such a first-line brand, only E1 grade plate, because the E0-class plate is the European standard, and E1-class plate is the national standard. Now many businesses boast their own wardrobe sheet is done with E0, which is actually in the use of consumers, we do not be cheated.

- Q:Is the PS board not an acrylic board?

- PS board and acrylic board is not a board. PS plastic components, poor transparency, Pan-blue, not wear-resistant, the price is low, does not apply to the word, you can do some of the appropriate splint painting. Acrylic board is extracted from the oil, high transparency, good wear resistance, the price may be higher, apply to do light boxes, crystal characters, transparent panels, cosmetics display stand, there is the company's LOGO wall are using acrylic To do it.

- Q:PCB aluminum plate plate an oily size is how much

- At present the conventional PCB aluminum substrate size of 400 * 1200mm, 500 * 1200,600 * 1200mm three

- Q:Bathroom and kitchen ceiling selection of what kind of plate is better?

- I just renovated in October, the kitchen and bathroom is used in nano-board. However, I chose the white, 300 * 600 specifications, four pieces together, the corner looks like a round, very nice to see. It is said that nano-board easy to care. However, I do not like cooking, and now not to the time of cleaning, can not tell. Just look, look at the bathroom and the kitchen more grade. I hope you can choose the style you like.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

extrude PVC foam sheet in Plastic Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords