Expanded Metal Mesh For The Constriction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

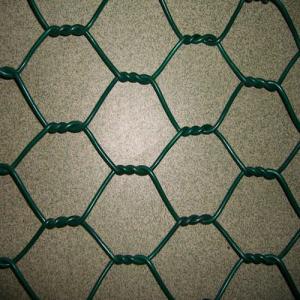

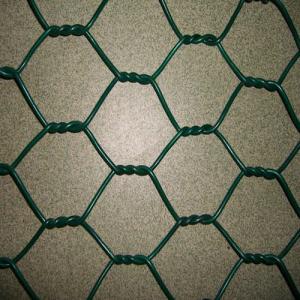

Expanded metal mesh can be used for security guarding and fences with its features of uniform structure, economic cost and great strength. Light type expanded metal is used in common fencing while heavy type expanded metal is used for security guarding.

Expanded metal mesh for common fences is diamond opening mesh. This kind of metal fence is popularly used in gardens, schools, general fencing for living area and industrial sites.

Technical terms:

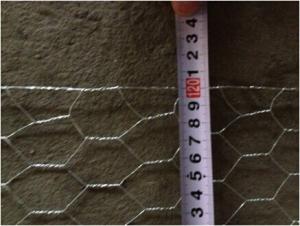

SWD: 2.5mm-50mm (Short Way of the Diamond), the distance from the middle of the bond on one side to the middle of the bond on the opposite side.

LWD: 3mm-100mm(Long Way of the Diamond) is the distance across the largest dimension of the diamond measured halfway between the diamonds.

Width: 0.5m-2.7m, Length:1m-3.6m

Thickness(gauge): Up to 8mm, Original thickness of metal before expanding.

Strand Width: 0.3mm to 8mm, Amount of metal between diamonds to produce one strand.

SWD, LWD Direction: Parallel to Length or Parallel to Width

- Q:Why do you want to shop a barbed wire?

- Brush the second time mortar, pay attention to the cement composition of the mortar than the first pass is low, and plastering the wall should do the treatment of water, the wall of the draft should be no less than 3cm depth, wiping the second pass Of the time, the first gray should have the necessary strength, so that after the wire hanging up there will not be cracks!

- Q:How does proe draw wire mesh?

- this curve you can draw their own equation can also be used to generate, I used here instead of sine curve example, sketched out a curve ,

- Q:How does the "jagged" on the back of the knife cut the barbed wire?

- There are a lot of landmines, and there are limitations in the mine warfare, but there are limitations,

- Q:This material of the barbed wire in the water I do not know how long?

- Protection and shielding effect of the outermost layer of glue is insulated, the role of fire inside some iron / copper layer, is the protection and shielding effect of the innermost copper wire, is the current effect, used for conductive transmission

- Q:Is the warm tube laid on top of the steel wire or below?

- and that the road is broken, then the loop must be replaced by all the warm pipe, which means that your room layout of the road to warm all the area to all Out of all to replace the new pipe to replace.

- Q:What is the mesh in the wire mesh specification?

- In countries and regions using imperial units of measurement, the mesh size is expressed in holes / inch or lines / inch. The mesh can generally indicate the degree of tightness between the wire and the wire of the screen.

- Q:Barbed wire fence is what the iron ring

- The wire rod is twisted by a fully automated barbed wire machine. Folk commonly known as Tribulus terrestris, barbed wire, thorn line. Type: single wire twist and double wire twist. Raw materials: high quality low carbon steel wire.

- Q:How is the wire mesh made

- First of all, the application of electrolytic pickling, high pressure flushing, card electric drying of the new technology successfully tested the continuous production of the wire drawing, the drawing process from the intermittent production into a continuous production, weakened the labor intensity and reduce the metal consumption.

- Q:In the chemical experiment, how does the wire mesh use? What are the effects?

- Increase the contact area. So that the reaction of iron to participate more intense (fast)

- Q:What is the effect of the wire mesh on the floor

- strong ground local load-bearing capacity: in the processing workshop, garage and other ground load larger room, to warm with wire mesh can improve the overall strength of the ground layer, to avoid ground cracking, collapse and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Expanded Metal Mesh For The Constriction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords