Excellent thermal resistance rock wool blanket with wire mesh Water repellent,asbestos fre

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

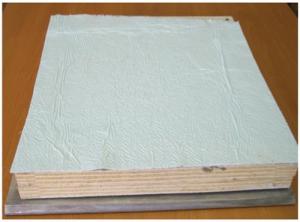

CNBM rock wool blanket with wire mesh Overview:

CNBM rock wool blanket with wire mesh is a robust insulation product stitched on one side with galvanized or stainless steel wire mesh and comes in various thickness and density.

CNBM rock wool blanket with wire mesh Product Specifications¼

Density(kg/m3) | Width(mm) | Thickness(mm) | Length(m) | Facing |

60-150 | 600 | 30-200 | 2.5 , 3 , 5 | wire mesh |

We can make special production according to your requirement.

Rock Wool Blanket With Wire Mesh Technical Parameters:

Item | Unit | Index | Standard |

Density | Kg/m3 | 60-200kg/m3 | GB5480.3 |

Average value of fiber | um | 4-7 | GB5480.4 |

Slag ball content (granule diameter) | % | 6 | GB5480.5 |

Volume water absorption | % | 2 | GB/GB16401-1996 |

Heat absorption | % | 1 | GB5480.7 |

Moisture resistivity | % | 98 | B10299-88 |

- Q:Where is the difference between glass fiber reinforced plastic cable tray and SMC cable trough?

- Process is differentRaw material is different.Product technical parameters are not the sameUse is not the sameThe price is different

- Q:What's the difference between a ductile iron well and a composite resin manhole cover?

- Composite manhole cover has the advantages of low cost, light weight, anti theft, the advantages of reducing the noise in city; corrosion protection, high performance composite resin covers SMC sheet products, acid, alkali and salt corrosion, rust and so on 50 or 150 DEG C for use in harsh conditions.

- Q:Composite manhole cover or cast iron well cover?

- Toward the color composite manhole cover is made of high temperature compression of SMC sheet, once formed, there is no recycling value, so it can be anti-theft

- Q:Where can I supply the SMC sheet machine set?

- Qingdao ultra Feng Plastic machinery, buy equipment also with technology and formula, after-sales service is very good

- Q:Why is unsaturated polyester resin used in sheet molding? Why don't short fiber moulding plastics use unsaturated polyester resins?

- Group materials and sheets are generally made without packaging and resin, but some of the other resins that are modified have thickening properties and molding requirements are also available.

- Q:How is glass fiber reinforced plastic water tank made?

- FRP hand lay up tank: made of resin glass cloth paste hand processing tank frame surface

- Q:What material is the resin composite manhole cover made of?

- Glass fiber yarn, filler, resin, curing agent, accelerator, mold, etc.

- Q:Why outdoor SMC table tennis table longer service life?

- SMC material is made up of fiber sheet material and is molded by high temperature. The water absorption rate is 0. SMC table tennis table chemical resistance performance is strong, anti climate strong, reasonable structure, enhance the stability in the premise of not reducing the performance of the products, and not easy to deform, paint film is more uniform, enhanced adhesion; surface crack. SMC table tennis table by forming a 1000T high temperature molding press, the table produced by the procedures of fine processing, table design and construction mechanics combined in surface stress with field type reinforcement reinforcement, and the material adding alkali silane reinforcing fibers.

- Q:What is polymer composite cable trench cover plate?

- From the point of view of cost performance, the general FRP grille grille cover is more economical and durable.This answer is recommended by the questioner

- Q:What are the raw materials for composite manhole covers?

- The composite manhole cover adopts high temperature and high pressure molding technology with high degree of polymerization, large density, good impact resistance and tensile strength, and has the advantages of wear resistance, corrosion resistance, no rust, no pollution, no maintenance, etc.. General composite manhole covers are also BMC composite cover and SMC composite manhole cover. SMC polymer composite manhole cover, Beijing Pan Asia Telecom's reliable, but also applied for the color of the patent

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Excellent thermal resistance rock wool blanket with wire mesh Water repellent,asbestos fre

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords