ERW Steel Pipe Welded Black ERW Steel Pipe ASTM A53

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Welded Black ERW Steel Pipe ASTM A53 :

Welded Black ERW Steel Pipe ASTM A53 is electric resistance welding, the abbreviation for ERW for transporting oil and natural gas vapor liquid objects, can meet the requirements of high and low pressure, the transport in the world with pipe sector accounted for a pivotal position.With sound reputation and high quality , we will offer clients a wonderful business experience.

2、Main Features of Welded Black ERW Steel Pipe ASTM A53 :

• High manufacturing accuracy

• Good visual effect

• Good view and appearance

• Good shape

• Reasonable price

• Strong heat dissipation ability

3、Welded Black ERW Steel Pipe ASTM A53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 1 - 33 mm |

Section Shape | Round |

Outer Diameter | 21 - 610mm |

Place of Origin | Tianjin, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Welded Black ERW Steel Pipe ASTM A53 :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

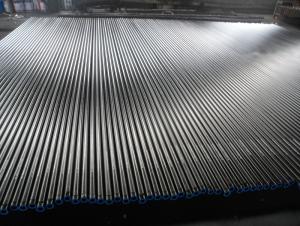

6、 Welded Black ERW Steel Pipe ASTM A53 Images:

- Q:How do steel pipes perform in high-altitude applications?

- Steel pipes perform well in high-altitude applications due to their strong structural integrity and resistance to extreme weather conditions. They can withstand the low temperatures and high winds commonly found at high altitudes without compromising their performance or durability. Additionally, steel pipes have excellent corrosion resistance, making them suitable for areas with high humidity or exposure to moisture. Overall, steel pipes are a reliable choice for high-altitude applications due to their strength, resilience, and ability to withstand harsh environmental factors.

- Q:Does seamless steel tube have a bend of 135 degrees?

- Other name: 90 degree elbow, right angle bend, love bend, punching elbow, pressing elbow, mechanism bend, welding elbow, etc..Usage: connect two pipes with same nominal diameter or different pipe, make the pipe bend at 90, 45, 180 degrees and various degrees.Bending radius is less than or equal to 1.5 times the diameter of the elbow. It is 1.5 times larger than the pipe diameter and belongs to the elbow

- Q:Are steel pipes resistant to ultraviolet (UV) radiation?

- Ultraviolet (UV) radiation poses a threat to steel pipes as they do not possess inherent resistance. This type of radiation has the potential to induce degradation and discoloration in various materials, including steel. However, the extent of harm inflicted depends on several factors, including steel type, duration and intensity of UV exposure, and the presence of protective coatings or finishes on the pipes. Generally, uncoated steel pipes are more vulnerable to UV damage compared to those treated with protective coatings or finishes. Coatings such as epoxy or polyethylene act as a shield against UV radiation, effectively preventing steel degradation and discoloration. Hence, it becomes crucial to consider the specific application and environment when selecting steel pipes and implementing suitable protective measures to ensure their durability and performance.

- Q:What are the different types of steel pipe connections for oil and gas pipelines?

- There are several types of steel pipe connections used for oil and gas pipelines, including threaded connections, welded connections, flanged connections, and grooved connections. Threaded connections involve screwing two pipe ends together using threads, providing a secure and leak-proof joint. Welded connections involve fusing pipe ends together using heat, creating a strong and durable joint. Flanged connections use a flange on each pipe end that is bolted together, providing a sturdy and easily removable joint. Grooved connections involve utilizing a groove on each pipe end, which is then locked together using a coupling, ensuring a reliable and flexible joint.

- Q:How do steel pipes withstand pressure?

- Steel pipes withstand pressure due to their inherent strength and resilience. The high tensile strength and durability of steel allow it to withstand the internal pressure exerted by fluids or gases flowing through the pipes. Additionally, the thick walls and cylindrical shape of the steel pipes distribute the pressure evenly, preventing any deformation or rupture. The seamless construction of steel pipes further enhances their ability to withstand pressure, making them a reliable choice for various applications in industries such as oil and gas, plumbing, and construction.

- Q:What are the different methods of testing steel pipes?

- There are several methods used for testing steel pipes, including visual inspection, ultrasonic testing, radiographic testing, magnetic particle testing, and hydrostatic testing. Visual inspection involves examining the pipes for any surface defects or abnormalities. Ultrasonic testing uses sound waves to detect flaws or inconsistencies within the pipes. Radiographic testing involves using X-rays or gamma rays to produce images of the pipes and identify any defects. Magnetic particle testing uses magnetic fields and magnetic particles to detect surface or near-surface defects in the pipes. Hydrostatic testing involves pressurizing the pipes with water to ensure they can withstand the specified pressure without leaks or failures.

- Q:What is the maximum bending radius for steel pipes?

- The maximum bending radius for steel pipes is determined by several factors, including the diameter of the pipe, the thickness of its walls, and the specific type of steel used. In general, pipes with larger diameters and thicker walls will have a greater maximum bending radius. However, it is crucial to adhere to industry standards and guidelines to ensure that the structural integrity of the pipe remains intact during the bending process. To obtain precise details regarding the maximum bending radius for steel pipes in various applications, it is recommended to consult the manufacturer's specifications or refer to relevant codes and standards, such as the American Society of Mechanical Engineers (ASME) B31.1 or B31.3.

- Q:How are steel pipes tested for leaks?

- Steel pipes are typically tested for leaks using various methods such as hydrostatic testing, pneumatic testing, or advanced technologies like ultrasonic testing. In hydrostatic testing, the pipe is filled with water or another liquid, and pressure is applied to check for any leaks. Pneumatic testing involves using compressed air or gas to pressurize the pipe and identify potential leaks. Ultrasonic testing employs high-frequency sound waves to detect any leaks or flaws in the steel pipes. These testing methods ensure the integrity and quality of steel pipes before they are put into use.

- Q:What are the different methods of pipe bending for steel pipes?

- There exists a variety of methods for bending steel pipes, each possessing its own advantages and limitations. 1. Manual Pipe Bending: The bending of steel pipes is achieved through the utilization of hand tools or a manual pipe bender. This method is best suited for small-scale projects or situations where only a few bends are necessary. However, it demands skill and precision to ensure accurate and consistent bends. 2. Rotary Draw Bending: This method involves the utilization of a mandrel, clamp die, and a bending die to bend the pipe around a stationary bend die. The mandrel serves to preserve the shape of the pipe and prevent wrinkling or collapsing during the bending process. Rotary draw bending is commonly employed to produce tight-radius bends with high accuracy and repeatability. 3. Induction Pipe Bending: In this method, a specific area of the steel pipe is heated using an induction coil, rendering it more malleable for bending. Once the desired temperature is attained, hydraulic or mechanical force is applied to bend the pipe. Induction bending is suitable for large-diameter pipes or situations requiring multiple bends in a single pipe. 4. Roll Bending: Also referred to as pyramid rolling, this method involves passing the steel pipe through three adjustable rolls that gradually shape the pipe into the desired form. Roll bending is suitable for generating large-radius bends and is frequently employed in the construction of spiral staircases, handrails, and structural applications. 5. Hot Bending: This method necessitates heating the steel pipe to elevated temperatures, typically accomplished using a furnace, in order to facilitate bending. Hot bending permits greater flexibility in shaping the pipe and is commonly used for large-diameter or thick-walled pipes. However, it demands specialized equipment and expertise to control the temperature and prevent distortion or damage to the pipe. When selecting the appropriate method of pipe bending for steel pipes, it is crucial to take into account factors such as the required bend radius, pipe diameter, wall thickness, and project specifications. Seeking the advice of an experienced pipe bending professional or engineer can assist in determining the most suitable method for a specific application.

- Q:How are steel pipes transported?

- Steel pipes can be transported through different means depending on their size, weight, and the distance they need to cover. The primary modes of transportation for steel pipes are trucks, trains, and ships. For shorter distances, trucks are often used to transport steel pipes. The pipes are loaded onto flatbed or specialized trailers designed to securely hold and transport them. Trucks are convenient for transporting steel pipes to nearby locations or construction sites, as they can easily navigate local roads and highways. For longer distances, trains are the preferred mode of transportation. Steel pipes are loaded onto flatcars, which are specifically designed to carry heavy loads. Trains offer a cost-effective and efficient means of transporting large quantities of steel pipes over long distances. They can accommodate pipes of various lengths and diameters, making them a versatile option. When it comes to international shipments or transportation over bodies of water, ships are commonly used. Steel pipes can be loaded into shipping containers or onto the deck of cargo ships. Shipping containers provide protection from weather conditions and ensure the pipes remain secure during transit. Specialized ships equipped with cranes can handle large and heavy pipes, making the transportation of oversized steel pipes possible. In certain cases, pipelines can be constructed to transport steel pipes directly from the manufacturing facility to the desired location. This method is commonly used for oil, gas, or water pipelines. By laying the pipes underground, the need for separate transportation is eliminated. Overall, the transportation of steel pipes involves a range of methods, including trucks, trains, ships, and pipelines. The choice of method depends on factors such as distance, quantity, and project requirements. Each method offers its own advantages and is selected based on considerations such as cost, efficiency, and logistics.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ERW Steel Pipe Welded Black ERW Steel Pipe ASTM A53

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords