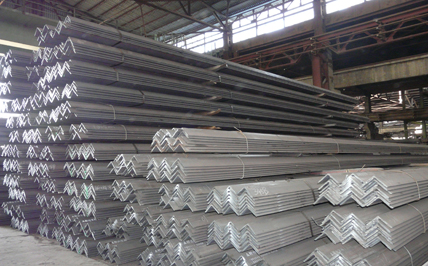

Equal / L Shaped / Unequal Mild Steel Angle Iron

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Equal / L Shaped / Unequal Mild Steel Angle Iron at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Equal / L Shaped / Unequal Mild Steel Angle Iron are ideal for structural applications and are widely used a variety of architectural and engineering structures, such as beams, bridges, ship; transmission tower, reaction tower; lifting transportation machinery; industrial furnace; container frame, warehouse goods shelves, etc

Product Advantages:

OKorder's Equal / L Shaped / Unequal Mild Steel Angle Iron are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q:Can steel angles be bolted together?

- Yes, steel angles can be bolted together. Steel angles are often used in construction and fabrication projects, and one common method of joining them is by using bolts. Bolting steel angles together provides a strong and secure connection that can withstand heavy loads and forces. The angles are typically drilled with holes at specific intervals, and bolts are inserted through these holes and tightened with nuts to hold the angles together. This method allows for easy disassembly and reassembly if needed, making it a versatile and practical choice for joining steel angles.

- Q:Can steel angles be used in construction?

- Yes, steel angles can be used in construction. Steel angles are commonly used structural elements in construction projects due to their versatility, strength, and cost-effectiveness. They are typically used for supporting and reinforcing various structural components, such as beams, columns, and walls. Steel angles are available in various sizes and thicknesses, making them suitable for a wide range of applications in construction. They can be easily welded, bolted, or fastened together, allowing for easy installation and customization on-site. One of the key advantages of using steel angles in construction is their high strength-to-weight ratio. This means that steel angles provide excellent load-bearing capacity while being relatively lightweight, making them ideal for structures that require strength without excessive weight. Additionally, steel angles offer excellent durability and resistance to environmental factors such as corrosion, fire, and pests. This ensures that structures built with steel angles have a longer lifespan and require less maintenance over time. Overall, steel angles are a versatile and reliable choice for construction projects, whether it be for residential, commercial, or industrial applications. Their strength, durability, and ease of installation make them a preferred choice among architects, engineers, and contractors.

- Q:How do you determine the appropriate thickness of a steel angle for a specific application?

- To determine the appropriate thickness of a steel angle for a specific application, several factors need to be considered. These factors include the load-bearing requirements, the length and span of the angle, and the structural design codes and standards applicable to the specific application. By evaluating these factors, engineers can calculate the required moment of inertia and bending capacity, allowing them to select the appropriate thickness of the steel angle that will provide sufficient strength and structural integrity for the intended use.

- Q:Can steel angles be used in the construction of parking garages?

- Yes, steel angles can be used in the construction of parking garages. Steel angles are commonly used as structural components in various construction applications, including parking garages. They provide strength, stability, and support for the overall structure and can be used for framing, bracing, and reinforcing. Steel angles are versatile and can be easily customized to meet the specific design requirements of parking garage construction.

- Q:Are steel angles suitable for rooftop installations?

- Yes, steel angles are suitable for rooftop installations. They are commonly used in construction for their strength and durability. Steel angles provide structural support and can be easily attached to rooftops to secure various installations such as solar panels, antennas, or HVAC equipment.

- Q:What are the different types of steel angles used in manufacturing?

- There are several different types of steel angles used in manufacturing, each with its own unique characteristics and applications. Some common types include: 1. Equal Angle: This type of steel angle has equal sides and angles, forming a 90-degree angle. It is commonly used for structural applications, such as framing and supports, where strength and stability are important. 2. Unequal Angle: As the name suggests, this type of steel angle has unequal sides and angles. It is often used for applications that require varying load-bearing capacities or to create different shapes in manufacturing processes. 3. L-Angle: Also known as L-shaped angles, this type of steel angle has a 90-degree bend with unequal sides. It is commonly used for reinforcing corners, as well as in construction and fabrication projects. 4. T-Angle: T-angles have a T-shaped cross-section, with one side extending vertically and the other extending horizontally. They are often used as structural supports or in applications where additional strength and rigidity are needed. 5. Flat Bar Angle: This type of steel angle has a flat surface on one side and a right-angle bend on the other. It is commonly used for bracing, supports, and framing in manufacturing and construction projects. 6. Slotted Angle: Slotted angles have holes or slots along their length, allowing for easy adjustment and customization. They are often used for shelving, racks, and storage systems in manufacturing and warehouse environments. These are just a few examples of the different types of steel angles used in manufacturing. The specific type of angle chosen will depend on the requirements of the project, including load-bearing capacity, structural integrity, and the desired shape or configuration.

- Q:How do steel angles compare to wooden beams?

- Steel angles and wooden beams possess distinct characteristics and abilities that render them suitable for diverse applications. Steel angles, being comprised of steel, demonstrate exceptional strength and longevity. They exhibit remarkable tensile strength and resist bending and warping even when subjected to substantial loads. This renders them an excellent choice for providing structural support in constructions such as buildings, bridges, and other similar projects. Moreover, steel angles possess the advantage of being non-combustible, thereby enhancing fire safety. Conversely, wooden beams offer their own set of advantages. As a natural material, wood is readily accessible and renewable, making it a more environmentally conscious option when compared to steel. Additionally, wooden beams possess an inherent aesthetic appeal, particularly in traditional or rustic designs. They can be effortlessly customized and shaped, enabling the creation of intricate and imaginative designs. Nevertheless, wooden beams do have certain limitations with regards to strength and durability. They do not exhibit the same level of robustness as steel angles and are susceptible to bending, warping, and rotting over time. Additionally, wood is combustible, which can pose safety concerns. In conclusion, both steel angles and wooden beams possess their own unique strengths and weaknesses. Steel angles excel in projects necessitating high strength and durability, while wooden beams offer a more natural and visually appealing option. Ultimately, the choice between the two depends on specific project requirements, budgetary considerations, and personal preferences.

- Q:Can steel angles be painted or coated after installation?

- Yes, steel angles can be painted or coated after installation. Painting or coating steel angles provides an added layer of protection against corrosion, enhances their aesthetic appeal, and can help them blend in with their surroundings.

- Q:Can steel angles be used in furniture manufacturing?

- Absolutely, steel angles are certainly applicable in the production of furniture. Steel angles are versatile structural components frequently utilized in a range of industries, including furniture manufacturing. They have the capability to function as supports, brackets, or reinforcements within furniture designs. Steel angles possess exceptional strength and stability, rendering them ideal for demanding applications. They can be joined together through welding, bolting, or screwing to form robust furniture frames or structures. Furthermore, steel angles are available in various sizes and shapes, thus enabling design flexibility and customization. All in all, steel angles offer longevity, stability, and adaptability, making them a highly favored option in the realm of furniture manufacturing.

- Q:What are the advantages of using steel angles in construction?

- Using steel angles in construction offers several advantages: 1. Strength and durability are key features of steel angles, making them an excellent option for construction projects that require structural support. They can withstand heavy loads and provide stability, ensuring the structure's longevity and safety. 2. Steel angles offer versatility due to their various sizes and dimensions, allowing for flexibility in design and construction. They can be easily cut, welded, and shaped to meet specific requirements, making them suitable for a wide range of applications. 3. Steel angles are cost-effective compared to other building materials like concrete or wood. They provide a cost-effective solution without compromising quality or structural integrity. 4. Steel angles have excellent fire resistance properties, making them a safer choice for construction. In the event of a fire, steel angles do not burn, warp, or emit toxic fumes, reducing the risk of structural collapse and providing more time for evacuation. 5. Using steel angles in construction promotes sustainability and reduces the demand for new steel production since steel is one of the most recycled materials in the world. Moreover, steel is 100% recyclable, ensuring minimal environmental impact. 6. Steel angles are lightweight and easily transported to the construction site, making them convenient for installation. Their ease of handling and quick assembly can help reduce construction time and labor costs. 7. Steel angles can be treated with protective coatings like galvanization to enhance their resistance to corrosion. This ensures that the structure remains durable and maintains its structural integrity even in harsh environmental conditions. In conclusion, the advantages of using steel angles in construction include their strength, versatility, cost-effectiveness, fire resistance, sustainability, easy installation, and resistance to corrosion. These qualities make steel angles a popular choice for various construction projects, ranging from residential buildings to large industrial structures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Equal / L Shaped / Unequal Mild Steel Angle Iron

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords