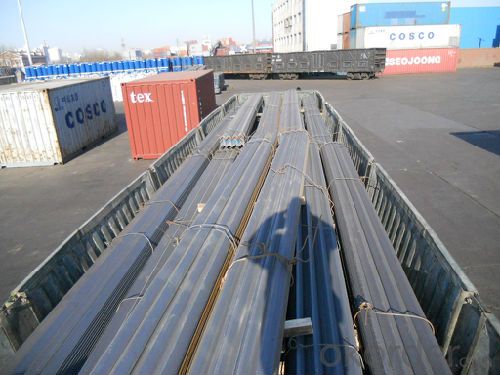

Equal Angle Steel Cold Rolled for Constraction Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Equal Angle Steel Cold Rolled for Constraction Application at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Equal Angle Steel Cold Rolled for Constraction Application are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Equal Angle Steel Cold Rolled for Constraction Application are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

304stainless steel angle bar

1.Short time delievry

2.Length:1-12M

3 New produced product, few rust

4 provide your Logo

Hot rolled 304stainless steel angle bar from China ShangHai

Hot rolled 304stainless steel angle bar from China ShangHai | |

| Size | 25mm*25mm-250mm*250mm (Customized size is acceptable, pls contact supplier for more details) |

Wall thickness | 3mm-20mm |

Length | 1m-12m ,Can follow customer’s requiremnts |

Internatioanal Standard | ISO 9001-2008 |

Standards |

ASTMA53/ASTM A573/ASTM A283/Gr.D/

BS1387-1985/

GB/T3091-2001,GB/T13793-92, ISO630/E235B/

JIS G3101/JIS G3131/JIS G3106/

|

Materials |

(We could offer Carbon, Alloy, Stainless steel) Q195,Q215,Q235B,Q345B,

S235JR/S235/S355JR/S355

SS440/SM400A/SM400B

MTC report will be offered together with the shipping document. |

Product Category | Metallurgy,Mineral &Energy |

Technique | Hot Rolled |

Packing | 1.Big OD:in bulk 2.Small OD:packed by steel strips 3.woven cloth with 7 slats 4.according to the requirements of customers |

Usage | Mechanical&manufacture,Steel strcuture, Shipbuilding,Bridging,Automobile chassis , Power tower, frame shef |

Main market | Middle East, Asia, Africa,Europe, America and Australia |

Country of origin | China |

Productivity | 15000 Metric Tons pet Month |

Remark | Payment terms :T/T ,L/C Terms of trade :FOB ,CFR,CIF ,DDP,EXW Minimum order : 10 tons Lead time: 3-15 working days (Can Fast delievery time because of the large stock size and well experience in the whole process of the international export business in this feild) |

Company Advantage

| 1, Fast response in reply 2, Good sales with reasonable price. 3, Good quality materials. 4, Fast lead time. 5, Rich experience in export business. 6, Well after sales service. 7, Flexible policy. |

Materials Workability | Easy to Weld, Cut, Form, and Machine |

Another Name | angle steel bar ,angle steel , steel angle , mild steel angle ,carbon steel bars, 304stainless steel angle bar |

Other processing service | Hot dipped Galvanized, pre-galvanized, coated, cutting, bending,punching as long as u could tell us the requirment. |

Shipment |

1, 1-10 tons it's ok to go by LCL

|

Other fittings

| Bolt with Anti-thift nut or any other required fittings (small amount order is acceptable) |

Contact

| TEL: +86-021-62153163 FAX: +86-021-62152536 (Good english speaking sales, welcome to call us if there has any questions. |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q:How do you calculate the torsional capacity of a steel angle?

- The torsional capacity of a steel angle can be calculated by determining the section modulus for torsion and multiplying it by the shear stress. The section modulus can be found using the dimensions of the angle, such as the width, height, and thickness. The shear stress is typically defined by the material's yield strength.

- Q:Can steel angles be galvanized or coated for additional protection?

- Yes, steel angles can be galvanized or coated for additional protection. Galvanizing or coating provides a protective layer that helps prevent corrosion and extends the lifespan of the steel angle.

- Q:What are the typical lengths of steel angles available in the market?

- The typical lengths of steel angles available in the market vary depending on the specific needs and requirements of the project. However, there are some common standard lengths that are readily available. These typically range from 20 feet to 40 feet, with incremental measurements such as 20 feet, 25 feet, 30 feet, 35 feet, and 40 feet. These lengths are commonly used in construction and industrial applications where steel angles are utilized for structural support, framing, and bracing purposes. It is important to note that customized lengths can also be obtained through special orders or fabrication, allowing for more flexibility in meeting specific project requirements.

- Q:Are steel angles suitable for manufacturing support brackets for pipes?

- Steel angles, indeed, are a fitting choice for fabricating support brackets for pipes. Renowned for their robustness and longevity, steel angles emerge as an optimal material for bolstering substantial loads, like pipes. They furnish exceptional structural reinforcement and exhibit the capacity to endure the weight and pressure exerted by pipes. Furthermore, steel angles boast resistance against corrosion, a crucial attribute when confronted with pipes that may encounter moisture or chemicals. Their adaptability permits an array of design alternatives, simplifying the customization of support brackets to accommodate specific pipe sizes and configurations. In conclusion, steel angles offer a dependable and pragmatic alternative for manufacturing support brackets for pipes.

- Q:Can steel angles be used in mining or quarrying machinery?

- Steel angles are indeed applicable in mining or quarrying machinery. They offer structural support and reinforcement to different machinery components used in these sectors. Frames, supports, and brackets for equipment like crushers, conveyors, and screens are often constructed using steel angles. Due to their high strength and durability, steel angles can withstand the heavy loads, vibrations, and harsh operating conditions commonly experienced in mining or quarrying operations. Moreover, steel angles can be easily fabricated and welded to meet specific design needs, making them a flexible option for machinery applications in these industries.

- Q:What are the considerations for selecting the appropriate steel angle length?

- When selecting the appropriate steel angle length, there are several considerations to keep in mind. Firstly, the intended application and usage of the steel angle should be considered. This includes factors such as the load-bearing capacity required, the structural design of the project, and any specific engineering or architectural requirements. Secondly, the dimensions and measurements of the project should be taken into account. This involves considering the overall size and shape of the structure, as well as the specific location and orientation where the steel angle will be installed. Additionally, the availability and cost of different steel angle lengths should be considered. It is important to assess the cost-effectiveness and availability of different lengths to ensure that the chosen length aligns with the project budget and timeframe. Lastly, it is crucial to consult industry standards and regulations when selecting the appropriate steel angle length. Adhering to specific guidelines and codes ensures the safety and compliance of the structure, and helps to avoid any potential issues or risks in the future. By considering these factors, one can make an informed decision when selecting the appropriate steel angle length for their specific project.

- Q:Can steel angles be used for manufacturing vehicle frames?

- Yes, steel angles can be used for manufacturing vehicle frames. Steel angles provide structural support and are commonly used in the construction of vehicle frames due to their strength, durability, and ability to withstand heavy loads.

- Q:How do steel angles contribute to sustainable construction?

- Steel angles contribute to sustainable construction in multiple ways. Firstly, steel is an incredibly durable and long-lasting material, which means that structures built using steel angles will have a longer lifespan compared to those made with other materials. This reduces the need for frequent repairs or replacements, thus minimizing waste and reducing the overall environmental impact of construction. Secondly, steel is a highly recyclable material. At the end of a structure's life cycle, steel angles can be easily recycled and repurposed for other construction projects. This reduces the demand for new steel production, which is energy-intensive and can result in significant carbon emissions. Additionally, steel angles offer design flexibility, allowing architects and engineers to create more efficient and innovative structures. This can lead to optimized building designs that require less energy for heating, cooling, and maintenance, contributing to energy savings and reduced greenhouse gas emissions. Moreover, steel angles are lightweight yet incredibly strong, resulting in less material usage and reduced transportation costs. As a result, the overall carbon footprint associated with steel construction is lower compared to other materials. Furthermore, steel angles have excellent fire resistance properties, making them a safer choice for construction. This increases the longevity of structures and reduces the risk of damage or destruction during fires. Consequently, the need for rebuilding or reconstructing is reduced, leading to less material waste and environmental impact. In conclusion, steel angles contribute to sustainable construction through their durability, recyclability, design flexibility, energy efficiency, lightweight nature, fire resistance, and overall reduced environmental impact. By incorporating steel angles into construction projects, we can create more sustainable and environmentally friendly structures that benefit both the present and future generations.

- Q:Can steel angles be used for manufacturing machinery?

- Yes, steel angles can be used for manufacturing machinery. Steel angles are commonly used in the construction industry as structural components due to their strength, durability, and cost-effectiveness. In machinery manufacturing, steel angles can be utilized for various purposes, such as framing, support structures, brackets, and mounting components. They provide stability and rigidity to the machinery, ensuring its structural integrity. Additionally, steel angles can be easily welded, bolted, or riveted, allowing for flexible and efficient fabrication processes. Overall, steel angles are a versatile and reliable choice for manufacturing machinery.

- Q:How can steel angles be cut to size?

- Steel angles can be cut to size using various methods such as sawing, shearing, or plasma cutting.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Equal Angle Steel Cold Rolled for Constraction Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords