EPS sandwich panel for roof hot sell from china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPS sandwich panel for roof hot sell from china

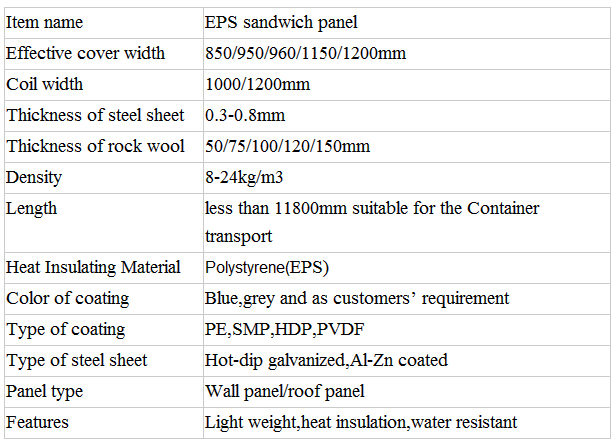

Description of EPS Sandwich panels:

Pictures of EPS sandwich panels

EPS Sandwich Panel advantages

1 High load bearing capacity at low weight, fast and economic construction

2 Effective and durable thermal insulation,signifcantly reduce the amount of energy required to keep building within a comfortbale temperature range.

3 Absolute water and vapour barrier,reduce air-leakage /infiltration rates

4 Air-tightness for controlled environment,eliminates thermal bridging

5 Long life,low maintenance,recyclable and reusable,most cost effective insulation material available,no need of external and internal decoration.

Shorter lead times and prompt delivery

- Q:The size of a standard sandwich panel is wide and wide

- Width is generally 1 meter, the length is not limited, because taking into account the transport, usually between the length of 3-18 meters. Sandwich is divided into polyurethane, rock wool, glass wool, polystyrene, and so on, the general thickness of 50mm.75mm.100mm, thicker can do.

- Q:Color steel sandwich panel wall too heavy how to install?

- Fixed the area surrounded by the house. And then wipe with a sandwich panel inside, remember to play the following rivet yo sandwich board on a piece of a piece of sandwich (the sandwich plate itself slot) corner of the seat to pull the window with aluminum is empty out, so you can save a little (Of course you can dig your own wall in the installation of the wall can also be empty) out of the window to be filled with trough aluminum in the installation of plastic windows can be a door on their own in a full version of the cut with the top of the aluminum roof with angle iron and The following wall panels are connected and screwed.

- Q:What is the polyurethane sandwich board material

- Double-sided color steel, the middle of the polyurethane sandwich composite panels Generally used in the roof of the building roof, the board has a good insulation, heat insulation, noise effects, and polyurethane does not help combustion, in line with fire safety. Upper and lower board plus the common role of polyurethane, with high strength and stiffness, the lower plate smooth and smooth, clear lines, increase indoor aesthetics, flatness. Easy installation, short duration, beautiful, is a new type of building materials.

- Q:Sandwich board insulation roof sets what the amount of

- The so-called sandwich panels, in fact, should be color steel insulation board, right? If you can, you can set the color steel roof, but under normal circumstances the color steel roof is a single layer of color plate, you are the insulation board, you only need to take color steel roof and then the quota inside the single layer of steel plate for color steel Insulation sandwich board so that the provinces and cities are not the same as the amount of fixed content, the specific depends on your local quota requirements.

- Q:Will the Yanmian sandwich color steel plate of the plant can reach the fire two grade requirements?

- Yanmian sandwich color of the core material is basalt and other natural ore as the main raw material, the high temperature melt into the fiber, adding the right amount of binder, curing and made. Is the same type (sandwich panel series) in the fire resistance of the strongest of a new type of fire board. Applicable to drying room, paint room, industrial equipment, construction, ship insulation, noise, etc., at the same time for electronic clean room, clean room, explosion-proof fire shop ceiling, partition and so on. Fire time is 80 minutes. Some information on "with 600 ℃ fire resistance, fire rating to A level."

- Q:Lightweight insulation color steel sandwich board clip what the core

- Color steel plate sandwich material is divided into foam color steel plate (chemical name for the polystyrene color plate), rock wool color plate, polyurethane color plate, paper honeycomb sandwich panels, glass wool color plate.

- Q:We want to build the activities of the board room is used as a dormitory, what materials used sandwich board good? What is the price of polystyrene board and rock wool board? As a dormitory board room in the height of the national standard? How high should it be?

- Mainly to see the use of activities, fire or rock wool sandwich board is good

- Q:What is the name of the board?

- Where there are ghostboard (anti-board), the BUG has long been TL closed. In the board room, mainly two kinds of boards, red plate and seconds board. Seconds board need to have the ability to support, the ability is less than seconds. The so-called red plate is to run one step, and then take off scratch board, the most suitable for PF.

- Q:Color steel plate wall how many meters a general support, corrugated color plate non-sandwich panels

- Is there any angle between the top and bottom of the color plate? If not, the two panels at the junction should be set up a support point. If there is, 2-3 sets of color board can be set up to support, depending on the size of the project area average annual wind. We usually set up a 2 support.

- Q:What are the varieties of foam sandwich panels? what is the price?

- Foam sandwich panel is made of OKorder Wang Teng Color Steel Co., Ltd. is made of advanced technology, foam sandwich panel Product performance: color plate thickness 0.2mm ~ 1.0mm Core thickness: 50mm ~ 250mm Effective height: 1000mm, 1200mm Applicable scope: workshop, office cabinet wall, steel structure exterior wall maintenance, decorative building materials, activities, office buildings and other fire rating: B3 (flame retardant: melting) moisture absorption: 3.9 (%) foam sandwich panels Features: It has a wide range of applications, especially for temporary facilities such as offices, warehouses and fences for construction sites. It is a wide range of applications, such as office buildings, warehouses, fences. And so on, but also reflects the modern construction site of civilized construction, especially in the rapid installation and put into use, can be equipped with removable, material turnover index, there are obvious advantages, a substantial reduction in temporary construction site costs, Is indispensable for new lightweight building materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPS sandwich panel for roof hot sell from china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords