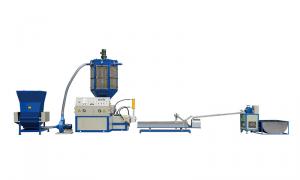

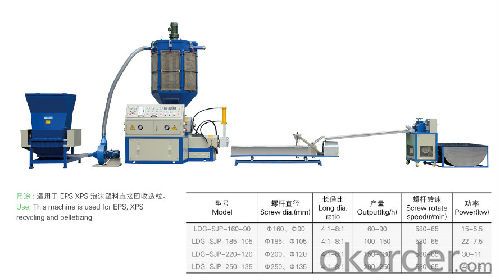

EPS Foam Recycling And Pelletizing Line LDG-SJP-160-90

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Use of EPS Foam Recycling And Pelletizing Line LDG-SJP-160-90

This machine is used for EPS ,XPS recycling and pelletizing, especially for sorting materials and transform rubbish into treasure. It is an ideal choice for environmental protection of the supermarket and the utility areas.

Features of EPS Foam Recycling And Pelletizing Line LDG-SJP-160-90

The machine adopt the fast compact , fast melting , extruding with filter , whole line design to recycling the material into the granules.The hole diameter of stamped sieve plate can be custom-made according the user's requirements.motor:15kw output:60-90kg/h

Packaging & Delivery

| Packaging Details: | Packed in wooden case,side screw force feeder pelletizing line |

|---|---|

| Delivery Detail: | Delivery Within 30-45 Working Days,side screw force feeder pelle |

Kindly feel free to contact with me if you need more detail informations.

And if convenience for you,welcome to visit our factory to know more about our machine.

- Q:We are 6mm diameter pipe cutting hole, pipe material for the PVC material, and the nasal oxygen tube hole is almost empty, elliptical small, short axis 2.5, 4.5 axis machining tool lathe is oval, circular edges, and then pressed into elliptical shape blade fixture, cutting blade is very sharp cutting requirements, good toughness what is the most suitable, wear-resistant, steel processing, help master pointing, high reward

- The D512 electrode is the core of steel, you find several of these electrodes to knock coating, with 4mm of the right. If I can't find it, I can send you some to try.

- Q:What is the best way to cut POM plastic?

- Band sawing machine processing of POM is generally not heated and melted, speed, high efficiency, and with coolant function (the cooling water pump), hand or electric saw might be added in cooling.

- Q:An electric tool for cutting plastic pipes: saw PVC hard polythene tubing 50-200

- Large caliber profile cutting machine, metal saw blade. Portable angle saw is also a metal saw. Saber saw can.

- Q:Cut PVC plastic, what saw blade?

- Should be able to use large right aluminum alloy saw blade 405x2.8x25.4x160THow much do the specific size, you can ask the Chi Xinhang tool can cut effective solution for Aluminum Alloy saw blade grinding machine at.

- Q:Do you have any experience in cutting plastic products at high speed, especially PP products?;

- Electromagnetic heating can improve the efficiency of energy utilization, increase the heating speed and improve the temperature control accuracy;Light industry, canned and other plastic packaging sealing, etc.The electromagnetic characteristics of the boiler by fast heating boiler industry, to abandon the traditional boiler heating mode, only the heating process in the boiler outlet, the water is heated in the flow, fast heating speed, save space.

- Q:How do you cut plastics?

- This can see you to the plastic, can be used for plastic nature of softer soluble properties at high temperature.

- Q:I want to cut this piece of plastic into four pieces and cut it out of place. What tools do you use?. Because the quantity is not much, so must be fast. A machine or a knife will do.Come and study it! Give me the answer as soon as possible!

- I choose the angle mill for cutting sheet can be used but will be some danger in the cutting process the cutting sheet if broken easily hurt yourself when used to wear protective gloves for eye mask tool friction angle can be polished

- Q:the next surface count, specific how to operate? FivePlastic die cutting oblique top, the drawings require the upper surface number and drawing requirements, the next surface count, specific how to operate? Please write the detailed steps, master generous with your criticism, run this program!!If the scheme is feasible, offer a reward

- Is taken, or by height from line position to count.

- Q:For this point, what is cut into the plastic membrane shape?

- This should be manufactured by stamping die, metal stamping and custom principle is similar to the shape of the mold punching and blanking.

- Q:Wire cutting machine tools can be processed ABS and other engineering plastics?

- No, the cutting element must be a conductor. ABS in addition to injection molding, it is also convenient to use CNC.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPS Foam Recycling And Pelletizing Line LDG-SJP-160-90

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords