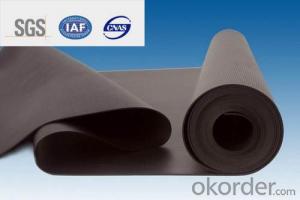

EPDM Waterproofing Roofing Membrane with 1.5mm 2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of EPDM Rubber Waterproof Membrane:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:Can waterproofing membranes be used in cold climates?

- Yes, waterproofing membranes can be used in cold climates. In fact, they are specifically designed to provide protection against moisture and water infiltration in various weather conditions, including cold temperatures. These membranes are typically made from durable, flexible materials that can withstand freezing temperatures without cracking or deteriorating. Additionally, some waterproofing membranes come with added features like thermal insulation, which helps to prevent heat loss and maintain a comfortable indoor environment in cold climates. Overall, waterproofing membranes are an effective solution for ensuring the integrity and longevity of structures in cold weather conditions.

- Q:Can a waterproofing membrane be used in areas with seismic activity?

- Yes, a waterproofing membrane can be used in areas with seismic activity. Waterproofing membranes are designed to provide a protective barrier against water infiltration, and they can be applied to various surfaces including those in seismic-prone regions. However, it is important to consider the specific requirements and recommendations of the manufacturer and consult with structural engineers to ensure that the membrane and its installation are suitable and compliant with seismic design considerations.

- Q:Polyurethane and SBS membrane waterproof

- SBS membrane, also known as modified asphalt waterproofing membrane, asphalt waterproof material; ?Polyurethane is rubber and plastic mine waterproof material;

- Q:Are there any environmental considerations when using a waterproofing membrane?

- Yes, there are several environmental considerations when using a waterproofing membrane. Firstly, the production and disposal of these membranes can have a negative impact on the environment due to the energy and resources required. Additionally, the chemicals used in some waterproofing membranes can be harmful to the environment and may leach into the soil or water systems. It is important to choose eco-friendly and sustainable options, such as those made from recycled materials or natural alternatives, to minimize the environmental impact. Regular maintenance and proper disposal of the membrane at the end of its life cycle are also crucial to ensure minimal harm to the environment.

- Q:Is a waterproofing membrane resistant to root penetration?

- Yes, a waterproofing membrane is typically resistant to root penetration.

- Q:Can a waterproofing membrane be used for planter boxes?

- Yes, a waterproofing membrane can be used for planter boxes to prevent water leakage and protect the surrounding surfaces from moisture damage.

- Q:Can a waterproofing membrane be used for a parking garage deck protection?

- Yes, a waterproofing membrane can be used for parking garage deck protection. A waterproofing membrane is specifically designed to prevent water infiltration and protect the underlying structure from moisture damage. In the case of a parking garage deck, where constant exposure to water, vehicular traffic, and potential chemical spills can occur, a waterproofing membrane can provide an effective barrier against these elements. By applying a waterproofing membrane to the parking garage deck, you can prevent water from seeping through the concrete and reaching the underlying steel reinforcement. This helps to avoid corrosion and deterioration of the structure, extending its lifespan and reducing the need for costly repairs or replacements. Furthermore, a waterproofing membrane can also protect the deck from other potential sources of damage, such as oil or chemical spills from vehicles. It creates a barrier that prevents these substances from penetrating the concrete and causing stains or deterioration. Additionally, a waterproofing membrane can enhance the overall durability and strength of the parking garage deck. It can help to minimize cracking, spalling, and other forms of concrete damage that can occur due to freeze-thaw cycles, temperature fluctuations, or heavy loads. Overall, using a waterproofing membrane for parking garage deck protection is a highly recommended solution to ensure the longevity and structural integrity of the parking facility. It provides a reliable defense against water infiltration, chemical spills, and other potential sources of damage, ultimately reducing maintenance costs and extending the lifespan of the parking garage deck.

- Q:Can a waterproofing membrane be used on tunnels with water drainage systems?

- Yes, a waterproofing membrane can be used on tunnels with water drainage systems. A waterproofing membrane is designed to provide a protective barrier against water penetration and can effectively prevent water leakage into the tunnel. However, it is important to ensure that the waterproofing membrane is compatible with the specific water drainage system in place. The membrane should be installed in such a way that it does not obstruct or interfere with the functioning of the drainage system. Additionally, proper consideration should be given to the design and installation of the drainage system to ensure efficient water management and prevent any potential issues that could compromise the effectiveness of the waterproofing membrane. Overall, with proper planning and installation, a waterproofing membrane can be successfully used in tunnels with water drainage systems to ensure the overall integrity and longevity of the structure.

- Q:Can a waterproofing membrane be used on aluminum surfaces?

- Indeed, aluminum surfaces can benefit from the application of a waterproofing membrane. Such membranes possess great versatility, enabling their use on a wide range of surfaces, including aluminum. Their purpose is to create a safeguarding barrier against water and moisture, effectively preventing any potential leaks or water-related harm. By employing a waterproofing membrane on aluminum surfaces, the material's longevity can be significantly extended as it remains protected from the detrimental effects of corrosion and rust, which are often triggered by water exposure. Nevertheless, it is imperative to carefully select a waterproofing membrane that is both compatible with aluminum and suitable for the specific application in order to achieve the most optimal outcomes.

- Q:Can a waterproofing membrane be used on foam block surfaces?

- Foam block surfaces can benefit from the use of a waterproofing membrane. Foam blocks, like expanded polystyrene (EPS) or extruded polystyrene (XPS), are commonly utilized for insulation in buildings. However, they are not naturally waterproof and can absorb moisture if exposed. To safeguard against water infiltration and potential harm, the application of a waterproofing membrane is recommended. This membrane acts as a protective barrier, preventing water from penetrating the foam and safeguarding it against issues caused by moisture, such as mold, mildew, or degradation. Selecting a waterproofing membrane that is compatible with foam block surfaces is crucial, and it is essential to adhere to the manufacturer's instructions for proper application. It is also advisable to seek guidance from a professional or building engineer to ensure the correct waterproofing solution is chosen for the specific foam block application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPDM Waterproofing Roofing Membrane with 1.5mm 2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords