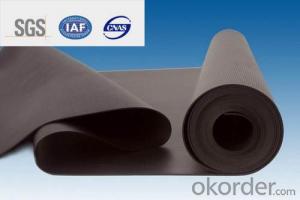

EPDM Waterproofing Roofing Membrane with 1.2mm 1.5mm 2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of EPDM Rubber Waterproof Membrane:

Waterproofing layer is imperfect: It’s hard to completely avoid weak points or breakages, which makes waterproofing layer with deficiencies or hidden defects more or less.

The main structure is with defects: It’s hard to completely avoid construction joint, deformation joint and small fissures in structure.

If there are weak points or breakage, water gets in and flude-channeling happens between the main structure and the waterproofing layer. In such cases, once the main structure is with defects, seepages would occur.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

| EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

| Property | Test Method | Units | Mininum ASTM | |

| D-7465 | ||||

| Sl | Eng | |||

| Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

| Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

| Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 +15/-10% | 0.04 +15/-10% |

| Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

| Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

| Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

| Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

| Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

| Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

| Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

| Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

| Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

| Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

| Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

| Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

| Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

| Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

| Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

| Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

| Chronic Toxicity Screening | EPA/600/4-89/001 ASTM E-729 | Method 1000.0 | Pass | Pass |

Applications of EPDM Rubber Waterproof Membrane:

Waterproofing, anti-seepage and moisture proof of side walls of basements, baseboards, head plates and roofs.

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:Can a waterproofing membrane be used in conjunction with a drainage system?

- Yes, a waterproofing membrane can be used in conjunction with a drainage system. In fact, it is often recommended to use both together for effective waterproofing and drainage in areas such as basements, roofs, and foundations. The waterproofing membrane acts as a barrier to prevent water from seeping through the surface, while the drainage system helps to remove any excess water that may accumulate. By combining these two systems, it ensures a comprehensive solution to protect the structure from potential water damage.

- Q:Can a waterproofing membrane be applied to vertical surfaces?

- Yes, a waterproofing membrane can be applied to vertical surfaces. In fact, waterproofing membranes are commonly used on vertical surfaces such as walls, foundations, and retaining walls to protect against water infiltration. These membranes are specifically designed to adhere to vertical surfaces and provide a protective barrier against water, preventing moisture from seeping into the structure. The application process typically involves cleaning and preparing the surface, applying a primer if necessary, and then installing the waterproofing membrane using a suitable adhesive or mechanical fastening system. This ensures that the membrane forms a continuous and secure seal, effectively preventing water penetration. Overall, waterproofing membranes offer an effective solution for waterproofing vertical surfaces and are widely used in construction and building maintenance projects.

- Q:Can a waterproofing membrane be applied to existing structures or is it only suitable for new construction?

- A waterproofing membrane has the capability to be applied to both existing structures and new construction. These membranes are specifically designed to create a barrier against water infiltration, making them suitable for preventing water damage in various areas such as roofs, basements, and foundations. Whether it is an aged building or a recently constructed one, the application of a waterproofing membrane can effectively maintain the dryness of the structure and prevent problems associated with moisture, such as leaks, seepage, and mold growth. However, when applying a waterproofing membrane to an existing structure, it may be necessary to undertake additional preparation and surface treatment in order to ensure proper adhesion and efficiency. It is strongly advised to seek the guidance of an experienced waterproofing contractor who can evaluate the specific requirements of the structure and provide suitable solutions.

- Q:Can a waterproofing membrane be used on brick walls?

- Brick walls, being porous, can absorb water and moisture, leading to damage and deterioration. To combat this, a waterproofing membrane can be applied. This membrane acts as a barrier, preventing water from entering the bricks while still allowing moisture to evaporate. By keeping the bricks dry, it reduces the risk of issues like efflorescence, mold, and mildew. Additionally, it improves the thermal insulation of the walls, reducing heat loss and enhancing energy efficiency. It is crucial to select a waterproofing membrane specifically made for masonry surfaces to ensure proper adhesion and long-lasting protection.

- Q:Can a waterproofing membrane be used in interior or exterior applications?

- Yes, a waterproofing membrane can be used in both interior and exterior applications. It is commonly used in basements, bathrooms, and other areas prone to moisture and water infiltration. Additionally, it can also be applied to exterior surfaces such as foundations, roofs, and balconies to prevent water damage and maintain the integrity of the structure.

- Q:Can a waterproofing membrane be used in areas with heavy foot traffic?

- Yes, a waterproofing membrane can be used in areas with heavy foot traffic. In fact, many waterproofing membranes are specifically designed to withstand heavy use and abuse, making them ideal for high-traffic areas such as walkways, balconies, and parking decks. These membranes are typically made from durable materials like rubber, PVC, or modified bitumen, which are resistant to wear and tear. Additionally, some membranes have a slip-resistant surface to improve safety in areas where people are walking. It's important to choose a waterproofing membrane that is suitable for the specific application and meets the required durability standards to ensure long-lasting protection in areas with heavy foot traffic.

- Q:Can a waterproofing membrane be applied to concrete surfaces?

- Indeed, concrete surfaces can have a waterproofing membrane applied to them. These membranes are specifically designed to establish a barrier against the infiltration of water and can be utilized on various types of surfaces, including concrete. To apply the membrane onto the concrete surface, one can employ different methods such as brushing, rolling, or spraying. The application of the membrane creates a protective layer that effectively obstructs water from permeating the concrete and causing harm. This is especially crucial in areas where water exposure is extensive, such as basements, swimming pools, or outdoor concrete surfaces. Through the application of a waterproofing membrane, not only can you significantly enhance the durability and lifespan of the concrete surface, but you can also shield it from issues related to moisture, such as cracks, mold growth, or degradation.

- Q:Can a waterproofing membrane be used in below-grade applications?

- In below-grade applications, such as basements or underground structures, it is crucial to utilize a waterproofing membrane. This membrane serves as a barrier, preventing water infiltration and the resulting structural damage or moisture-related issues. These areas are particularly vulnerable to moisture and water damage, making the use of a waterproofing membrane necessary. By preventing water from seeping through the walls or floors, the membrane keeps the below-grade areas dry, thus safeguarding the building's integrity and creating a safe and habitable environment. Waterproofing membranes designed for below-grade applications are made of durable materials that are resistant to water and possess high tensile strength to withstand ground pressure. Furthermore, they are specifically designed to adhere tightly and securely to various substrates, such as concrete. In summary, incorporating a waterproofing membrane into below-grade applications is essential for maintaining a moisture-free and structurally sound space.

- Q:Can a waterproofing membrane be applied to curved surfaces?

- Indeed, it is possible to apply a waterproofing membrane to surfaces that have curves. Specifically designed methods and products are accessible for adhering to and covering such surfaces. These membranes possess flexibility, allowing them to be molded or stretched in order to conform to the shape of the curved surface, guaranteeing a tight and secure seal. While the application process may demand additional care and attention to ensure appropriate adhesion and coverage, the effective waterproofing of curved surfaces is certainly achievable.

- Q:Can a waterproofing membrane be used for exterior foundation walls?

- Yes, a waterproofing membrane can be used for exterior foundation walls. Waterproofing membranes are specifically designed to provide a barrier against water penetration and can be applied to the exterior surface of foundation walls to prevent moisture infiltration. This helps in protecting the foundation from potential damage caused by water, such as leaks, cracks, and deterioration.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPDM Waterproofing Roofing Membrane with 1.2mm 1.5mm 2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords