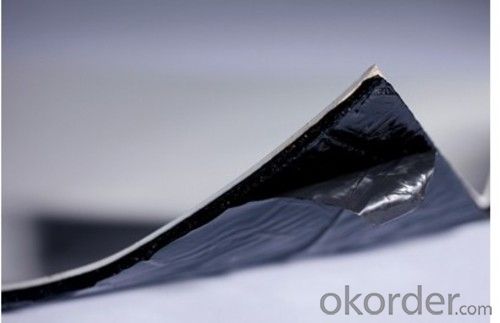

EPDM Waterproofing Membrane Used in Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Characteristic:

1.Excellent anti aging performance ,service life up to 50 years.

2.High extension rate,high tensile strength ,small size changes at heat treatment.

3.Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4.Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5.Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6.Convenient application ,solid joint ,no environment pollution.

7.Chemical corrosion resistance ,can be used for special occasions.

8.Good anti-perforated.

Applicable scope:

1.0mm 1.2mm 1.5mm 1.8mm 2.0mm EPDM waterproof membrane is widely used in roofs, basement, toilet, swimming pool, and all kinds of industry and civil building waterproofing, reservoir, bridge, underground, tunnel and dam waterproofing, especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation.

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q:Can a waterproofing membrane be used in commercial construction?

- Yes, a waterproofing membrane can definitely be used in commercial construction. In fact, it is often a crucial component of the building process. Waterproofing membranes are designed to provide a barrier against moisture, preventing water infiltration and protecting the structure from potential water damage. This is particularly important in commercial buildings where water can cause significant structural issues, such as mold growth, deterioration of materials, and even compromise the integrity of the building's foundation. Waterproofing membranes are commonly used in various areas of commercial construction, including basements, roofs, foundations, and even exterior walls. They are available in different forms, such as sheets, liquid coatings, or spray-applied membranes, offering versatility and adaptability to different construction scenarios. Overall, incorporating a waterproofing membrane in commercial construction projects is a wise investment to ensure the long-term durability and functionality of the building.

- Q:Can a waterproofing membrane be used for a parking lot pavement?

- Indeed, a waterproofing membrane can be utilized to fortify the surface of a parking lot. Essentially, a waterproofing membrane is a substance that is applied to a surface to obstruct the entry of water. Generally employed in the realm of construction, it serves to safeguard walls, roofs, and foundations from water-related harm. Nevertheless, it can also be employed in parking lot pavements to heighten their sturdiness and longevity. Parking lots are constantly exposed to a multitude of meteorological conditions, including rainfall, snowfall, and icy conditions. Over time, these elements can infiltrate the pavement, resulting in deterioration, cracks, and potholes. By applying a waterproofing membrane to the pavement, the infiltration of water can be significantly minimized, effectively averting these issues from arising. The waterproofing membrane acts as a barricade, effectively barring water from permeating the pavement and infiltrating the underlying layers. This serves to keep the pavement dry, preventing problems associated with moisture, such as damage caused by freezing and thawing. Additionally, it offers protection to the pavement against substances like chemicals and oils, as well as any other spills that may occur on the surface. Employing a waterproofing membrane for a parking lot pavement can prolong its lifespan and reduce the need for frequent repairs and maintenance. Furthermore, it can enhance the overall appearance of the parking lot by preventing the formation of unsightly cracks and potholes. However, it is crucial to consider the specific requirements of the parking lot when selecting a waterproofing membrane. Factors such as the amount of traffic, the prevailing climate, and the type of pavement material must be taken into account to ensure the effectiveness and durability of the waterproofing system. In conclusion, a waterproofing membrane can serve as a suitable solution for augmenting the performance and longevity of a parking lot pavement. It can provide protection against water damage, prolong the lifespan of the pavement, and diminish the necessity for costly repairs.

- Q:Are waterproofing membranes resistant to battery acid?

- Waterproofing membranes do not usually possess the necessary resistance against battery acid. Their main function is to create a barrier against water and moisture, and they are typically composed of materials like bitumen, rubber, or modified asphalt. Although these materials may exhibit some level of acid resistance, they are not typically engineered to endure the corrosive nature of battery acid. Battery acid, commonly sulfuric acid, can inflict substantial harm on various materials, including waterproofing membranes. If you are dealing with battery acid or find yourself in a situation where exposure to battery acid is a concern, it is advisable to employ materials specifically designed to withstand the corrosive effects of battery acid or seek professional assistance for appropriate solutions.

- Q:Can a waterproofing membrane be used for a fountain?

- Yes, a waterproofing membrane can be used for a fountain. Waterproofing membranes are designed to create a protective barrier against water, making them suitable for fountains to prevent leakage and maintain the structural integrity of the fountain.

- Q:Can a waterproofing membrane be used to repair existing water leaks or damage?

- Yes, a waterproofing membrane can be used to repair existing water leaks or damage. Waterproofing membranes are designed to create a barrier that prevents water from penetrating through surfaces such as roofs, walls, or foundations. By applying a waterproofing membrane to areas where water leaks or damage have occurred, it can effectively seal off the affected area and prevent further water intrusion. However, it is important to note that the success of the repair depends on the extent of the damage and the quality of the waterproofing membrane used. It is always recommended to consult with a professional to assess the situation and determine the best course of action for repairing existing water leaks or damage.

- Q:Are waterproofing membranes suitable for bridge abutments?

- Bridge abutments, the structures supporting the ends of a bridge, can benefit from the use of waterproofing membranes. Given their exposure to moisture and water, it is crucial to protect these structures. Waterproofing membranes serve as an effective barrier against water and moisture intrusion, making them an excellent solution for bridge abutments. These membranes, typically composed of materials like bitumen, PVC, or EPDM, possess high resistance to water penetration. Moreover, they offer additional protection against factors such as UV rays, chemicals, and temperature changes. By installing waterproofing membranes on bridge abutments, the risk of water damage, deterioration, and corrosion can be significantly reduced. Consequently, the bridge structure's durability and longevity are enhanced.

- Q:What is rigid waterproof, flexible waterproof?

- 3, not all waterproof only sub-rigid waterproof and flexible waterproof, such as metal roofing. Basement concrete structure waterproofing is usually not called rigid waterproof.

- Q:What are the different types of waterproofing membranes?

- There are several different types of waterproofing membranes that are commonly used in construction and building projects. These membranes are designed to prevent water from penetrating through walls, roofs, or other structures, and can be applied to various surfaces. 1. Bituminous Membranes: Bitumen-based waterproofing membranes are composed of a mixture of bitumen, polymers, and reinforcement materials such as fiberglass or polyester. They are commonly used in roofing applications and can be applied as a hot or cold process. Bituminous membranes provide excellent waterproofing properties and are durable. 2. PVC Membranes: Polyvinyl chloride (PVC) membranes are synthetic materials that are highly resistant to water, chemicals, and UV radiation. They are commonly used in roofing applications, especially for flat or low-slope roofs. PVC membranes are lightweight, flexible, and easy to install. They provide long-lasting waterproofing protection and are resistant to punctures and tears. 3. EPDM Membranes: Ethylene Propylene Diene Monomer (EPDM) membranes are synthetic rubber membranes that are commonly used in roofing applications. EPDM membranes are highly durable, flexible, and resistant to UV radiation, ozone, and extreme temperatures. They can be installed as a single-ply membrane or in combination with other materials. 4. TPO Membranes: Thermoplastic Olefin (TPO) membranes are a type of single-ply roofing membrane that is commonly used in commercial and industrial applications. TPO membranes are composed of a blend of polymers and reinforcement materials. They are highly resistant to water, chemicals, and UV radiation. TPO membranes are lightweight, flexible, and easy to install. 5. Liquid Applied Membranes: Liquid applied membranes are a type of waterproofing system that is applied as a liquid and cures to form a seamless and flexible membrane. These membranes can be made from various materials such as acrylic, polyurethane, or rubber-based compounds. They are commonly used for below-grade applications, such as basements or foundations, and can also be used for roofs or other surfaces. It is important to consider the specific requirements of the project and consult with a professional to determine the most suitable type of waterproofing membrane to ensure effective and long-lasting waterproofing protection.

- Q:Can a waterproofing membrane be used for swimming pools and water features?

- Swimming pools and water features can benefit from the utilization of a waterproofing membrane. These specialized membranes serve the purpose of creating a barrier that effectively prevents water from permeating surfaces. They have proven to be highly valuable in a variety of applications, such as swimming pools and water features, where their primary objective is to confine water within the designated area. These membranes are typically crafted from materials that possess water-resistant properties, enabling them to withstand continuous exposure to moisture without incurring damage. Furthermore, their flexibility allows for convenient installation and adaptation to fit pools and water features of varying shapes and sizes. In summary, the implementation of a waterproofing membrane is an efficient and dependable method of guaranteeing the durability and longevity of swimming pools and water features.

- Q:Can a waterproofing membrane be used on balconies and decks?

- Yes, a waterproofing membrane can be used on balconies and decks. In fact, it is highly recommended to install a waterproofing membrane to protect these areas from water damage. Balconies and decks are exposed to rain, snow, and other weather elements, which can cause water to seep into the structure and lead to issues such as rotting, mold growth, and structural damage. A waterproofing membrane provides a protective barrier that prevents water from penetrating the surface and directs it away from the structure. It is typically applied underneath the surface material, such as tiles or decking, and acts as a waterproof layer. This helps to extend the lifespan of the balcony or deck, ensuring its durability and maintaining its aesthetic appeal. Additionally, using a waterproofing membrane can also prevent water from dripping down to the areas below, which is particularly important for balconies located above living spaces. Overall, using a waterproofing membrane is an effective solution to ensure the longevity and functionality of balconies and decks.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPDM Waterproofing Membrane Used in Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords