EPDM Waterproof Rubber Membrane for Pond Liner

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Rubber Membrane for Pond Liner

Description Of EPDM Waterproof Rubber Membrane for Pond Liner:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Waterproof Rubber Membrane for Pond Liner:

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

Specifications of EPDM Waterproof Rubber Membrane for Pond Liner:

ITEM | STANDARO REQUEST | |

Tensile strength at breaking,normal temperature,Mpa | ≥7.5 | |

Elongation at breaking, % | ≥450 | |

Tearing strenght,KN/m | ≥25 | |

Bending at low temperature | ≤-40°C | |

Water impermeability,0.1Mpa×30min | Impermeability | |

Hot air aging 80°C×168h | Unchanging of tensile strength at breaking,% | ≥80 |

Unchanging of elongation at breaking,% | ≥70 | |

Appearance of 100% elongation | No crack | |

Property of anti alkali 10% Ca(OH)2×168h normal temperature | ≥80 | |

≥80 | ||

Applications of EPDM Waterproof Rubber Membrane for Pond Liner:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

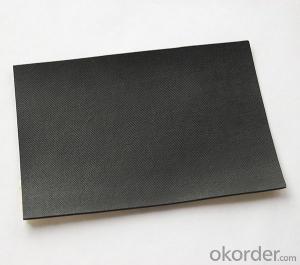

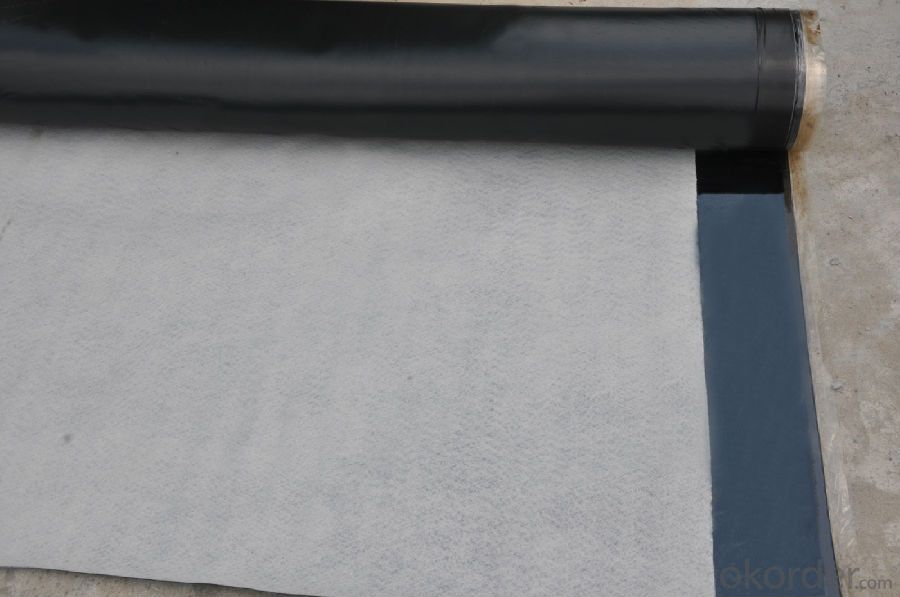

IMages of EPDM Waterproof Rubber Membrane for Pond Liner:

FAQ of EPDM Waterproof Rubber Membrane for Pond Liner:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:Can a waterproofing membrane be used in planter boxes or raised beds?

- Yes, a waterproofing membrane can be used in planter boxes or raised beds to prevent water leakage and protect the surrounding structures. A waterproofing membrane is typically made of materials such as rubber, PVC, or polyethylene, which create a barrier between the soil and the surrounding area. This barrier helps retain moisture within the planter box or raised bed, preventing water from seeping into the ground and potentially causing damage to the foundation or nearby structures. Additionally, a waterproofing membrane can also prevent the leaching of chemicals or fertilizers from the soil, improving the overall quality of the planting environment. Nevertheless, it is important to ensure proper drainage in planter boxes or raised beds to prevent waterlogging and root rot.

- Q:Can a waterproofing membrane be used for balconies and terraces?

- Yes, a waterproofing membrane can be used for balconies and terraces. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water penetration and damage. Balconies and terraces are exposed to outdoor elements such as rain, snow, and sunlight, which can cause moisture buildup and deterioration of the underlying structure. A waterproofing membrane acts as a barrier, preventing water from seeping through the surface and causing potential leaks, mold growth, or structural damage. It provides an effective solution to protect the balcony or terrace, ensuring its longevity and durability. Additionally, waterproofing membranes are available in different types and materials, allowing for flexibility in choosing the most suitable option based on the specific requirements of the balcony or terrace.

- Q:Can waterproofing membranes be used on elevator shafts?

- Yes, waterproofing membranes can be used on elevator shafts to prevent water infiltration and protect the structure from moisture damage.

- Q:Can a waterproofing membrane be used in tunnels or underground structures?

- Yes, a waterproofing membrane can definitely be used in tunnels or underground structures. In fact, it is highly recommended to use a waterproofing membrane in these types of environments to prevent water damage and leakage. Tunnels and underground structures are particularly prone to water infiltration due to their location and exposure to underground water sources. The waterproofing membrane acts as a protective barrier, preventing water from seeping into the tunnels or structures and causing potential structural damage or compromising the safety of the space. It effectively creates a watertight seal, ensuring that the interior remains dry and free from water-related issues such as mold, corrosion, or degradation of materials. Additionally, waterproofing membranes are designed to withstand the unique challenges of underground environments such as high water pressure, ground movement, and exposure to harsh chemicals. Therefore, using a waterproofing membrane is not only possible but essential for maintaining the longevity and integrity of tunnels and underground structures.

- Q:Can a waterproofing membrane be used for soundproofing purposes?

- Yes, a waterproofing membrane can be used for soundproofing purposes to some extent. While its primary function is to prevent water penetration, it can also help to reduce sound transmission. Waterproofing membranes are typically made of materials that have good acoustic properties, such as rubber or a combination of rubber and asphalt. These materials can absorb and dampen sound waves, thereby reducing the amount of noise that passes through a wall or floor. However, it is important to note that the soundproofing effectiveness of a waterproofing membrane may not be as high as that of specialized soundproofing materials like acoustic panels or insulation. Therefore, if soundproofing is the main goal, it is recommended to consider using dedicated soundproofing solutions in addition to or instead of a waterproofing membrane.

- Q:Are waterproofing membranes resistant to saltwater?

- Yes, waterproofing membranes are generally resistant to saltwater. These membranes are designed to create a barrier that prevents water from penetrating through surfaces such as roofs, walls, or foundations. They are made from materials like rubber, polyethylene, or PVC, which are inherently resistant to the corrosive effects of saltwater. This resistance allows waterproofing membranes to effectively protect structures and surfaces from water damage, even in saltwater environments. However, it is essential to choose a waterproofing membrane specifically designed for saltwater applications to ensure optimal performance and longevity.

- Q:Can a waterproofing membrane be used in areas with high water pressure?

- Yes, a waterproofing membrane can be used in areas with high water pressure. Waterproofing membranes are specifically designed to withstand and resist water penetration, making them suitable for areas with high water pressure. These membranes are typically made from materials such as rubber, PVC, or bitumen, which are highly durable and have excellent waterproofing properties. Additionally, waterproofing membranes can be reinforced with additional layers or fabrics to enhance their strength and resistance to water pressure. However, it is crucial to ensure that the waterproofing membrane is properly installed and meets the specific requirements of the area to ensure its effectiveness in high water pressure situations. Professional consultation and adherence to manufacturer guidelines are recommended to ensure the membrane's performance in such conditions.

- Q:Can a waterproofing membrane be used in parking garages?

- Yes, a waterproofing membrane can be used in parking garages. It is commonly used to protect the structure from water damage, such as leaks and corrosion, which can be caused by water infiltrating through the concrete. A waterproofing membrane helps to create a barrier that prevents water penetration, ensuring the durability and longevity of the parking garage.

- Q:Can a waterproofing membrane be used on precast iron surfaces?

- Yes, a waterproofing membrane can be used on precast iron surfaces. A waterproofing membrane is a thin layer of material that is applied to a surface to prevent the penetration of water or moisture. It can be applied to a variety of surfaces, including precast iron surfaces. The waterproofing membrane acts as a barrier, preventing water from seeping into the precast iron and causing damage such as rust or corrosion. This can be particularly important in areas where the precast iron surface is exposed to water or moisture, such as in outdoor installations or areas with high humidity levels. The use of a waterproofing membrane on precast iron surfaces can help to extend the lifespan of the structure and maintain its structural integrity.

- Q:Are there any specific considerations for installing a waterproofing membrane on stucco surfaces?

- Yes, there are specific considerations for installing a waterproofing membrane on stucco surfaces. Firstly, the stucco surface needs to be clean, dry, and free from any loose debris or contaminants. It is important to ensure that the stucco is properly cured before applying the membrane. Additionally, the choice of waterproofing membrane should be compatible with stucco, considering factors such as flexibility, breathability, and adhesion. Proper application techniques, including thorough coverage and proper overlap of the membrane, are crucial to guarantee its effectiveness. It is also advisable to consult with a professional to ensure the correct installation process and product selection for the specific stucco surface.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPDM Waterproof Rubber Membrane for Pond Liner

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords