EPDM Rubber Waterproofing Membrane Underground Leakage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

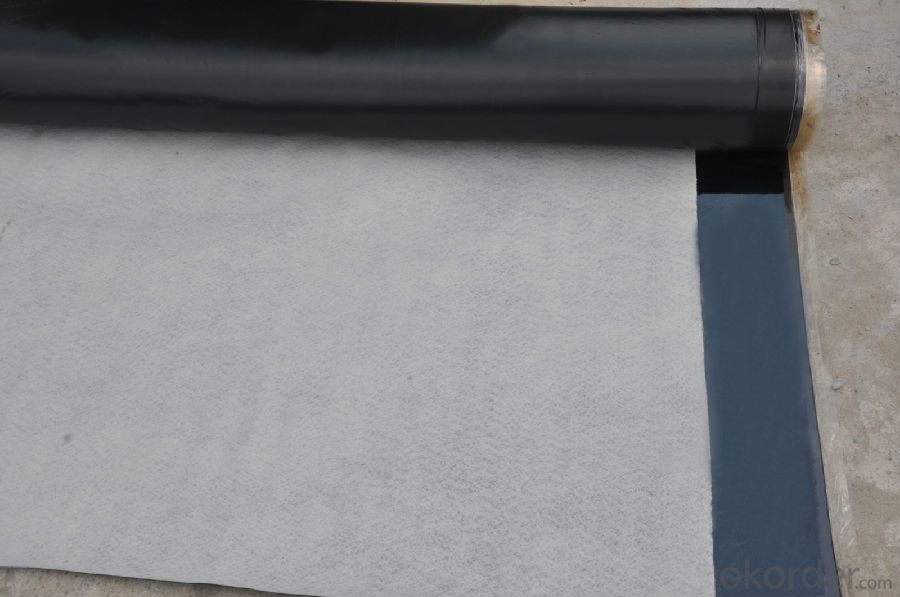

Introduction for EPDM Waterproofing Membrane:

Waterproof membrane for roof adopt the international advanced level cold feed extrusion continuous vulcanization process for the integration of production equipment and technology so that the system density of products is better and the products have no bubble sooth surface, no performance difference between vertical and horizontal.

Application of EPDM Waterproofing Membrane:

1.It is widely used in civil and industry construction.

2.The waterproof,dampproof of the roofs,basements,toilets etc;

3.And the waterproofing of subway,underground,bridges,car parking,tunnels,reserviors,pool etc.

4.SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions

5.APP specially suitable to areas of high temperature and of strong sunshine.

Specification of EPDM Waterproofing Membrane:

No. | Item | Unit | Standard Request | |

1 | Variation in Dimension | Thickness | % | ±10 |

Width | % | ±1 | ||

Length | % | No Negative Value | ||

2 | Tensile Strength at Break(Normal Temperature) | Mpa | ≥7.5 | |

Tensile Strength at Break(60ºC) | Mpa | ≥2.3 | ||

3 | Elongation at Break(Normal Temperature) | % | ≥450 | |

Elongation at Break(-20ºC) | % | ≥200 | ||

4 | Tearing Strength | KN/m | ≥25 | |

5 | Water Impermeability(30min) | * | 0.3Mpa Impermeability | |

6 | Bend Temperature | ºC | ≤-40 | |

7 | Heating Expansion/Shrinkage | Expansion | mm | ≤2 |

Shrinkage | mm | ≤4 | ||

8 | Hot Air Aging 80ºC x168h | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥70 | ||

9 | Property of Anti Alkali 10% Ca(OH)²x 168h normal temperature | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥80 | ||

10 | Elongation 40%,500x102 | * | No Crack | |

11 | Artificial Aging | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥70 | ||

Appearance of 100% elongation | * | No Crack | ||

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q:Can a waterproofing membrane be used for underground utilities?

- Yes, a waterproofing membrane can be used for underground utilities. It provides a protective barrier against water infiltration, preventing potential damage or deterioration to the utilities.

- Q:Can a waterproofing membrane be used for crawl spaces?

- Yes, a waterproofing membrane can be used for crawl spaces. Waterproofing membranes are commonly used in crawl spaces to prevent moisture and water infiltration, which can cause structural damage and promote mold growth. By installing a waterproofing membrane, it creates a barrier that keeps moisture out and helps maintain a dry and healthy crawl space environment.

- Q:Can a waterproofing membrane be used for roofing applications?

- Yes, a waterproofing membrane can be used for roofing applications. Waterproofing membranes are specially designed to provide a barrier against water penetration and are commonly used in various construction projects, including roofs. These membranes are typically made from materials such as synthetic rubber, thermoplastics, or modified bitumen, which are known for their durability and ability to resist water damage. Installing a waterproofing membrane on the roof can help protect the building from water leaks and moisture infiltration, which can lead to structural damage, mold growth, and other issues. The membrane is typically applied on the roof surface, providing a seamless and watertight layer that prevents water from seeping through the roof. Waterproofing membranes for roofing applications come in various types, such as sheet membranes, liquid or spray-applied membranes, or self-adhering membranes. Each type has its own advantages and suitability depending on the specific roofing requirements and construction conditions. In summary, a waterproofing membrane can indeed be used for roofing applications and is an effective solution to ensure a watertight and durable roof system.

- Q:How does a waterproofing membrane work?

- A waterproofing membrane is a barrier that is applied to a surface to prevent water from penetrating it and causing damage. The membrane is typically made of a flexible material, such as rubber or plastic, which is resistant to water. The primary function of a waterproofing membrane is to create a continuous layer of protection that prevents water from seeping through the surface it is applied to. This can be particularly important in areas that are prone to moisture, such as basements, roofs, and bathrooms. When a waterproofing membrane is applied to a surface, it forms a seamless and impenetrable barrier that prevents water from passing through. The membrane is typically installed in multiple layers to ensure maximum protection. These layers are often reinforced with materials like fiberglass or polyester to enhance their strength and durability. In addition to preventing water from penetrating a surface, a waterproofing membrane also helps to redirect water away from the area. The membrane is designed in a way that encourages water to flow towards drains or other designated outlets, effectively channeling it away from the protected area. Furthermore, a waterproofing membrane is also resistant to the effects of moisture, such as mold and mildew growth. By blocking the entry of water, it helps to maintain a dry and healthy environment. Overall, a waterproofing membrane is a vital component in protecting structures and surfaces from water damage. It provides a reliable and long-lasting solution for preventing leaks, seepage, and moisture-related issues, ensuring the longevity and integrity of the protected area.

- Q:How does a waterproofing membrane handle movement of a building due to settling or seismic activity?

- A waterproofing membrane is designed to accommodate the movement of a building caused by settling or seismic activity. It offers a flexible and elastic barrier that can stretch and contract with the building's movements, preventing any water penetration. When a building settles or experiences seismic activity, it can undergo significant structural movements. These movements can cause cracks, shifts, or changes in the building's foundation, walls, or floors. Without proper waterproofing, water can seep through these cracks or gaps, leading to water damage, mold growth, and structural deterioration. To address this, waterproofing membranes are typically made of materials that have excellent elongation and recovery properties. Elongation refers to the membrane's ability to stretch without tearing, while recovery refers to its ability to return to its original shape after being stretched. This flexibility allows the membrane to move with the building, rather than resisting or cracking under the stress. Moreover, waterproofing membranes are installed in a way that allows for horizontal and vertical movement. They are often applied in layers, with overlapping seams to create a continuous barrier. This layered approach accommodates any potential shifts or settlements in the building by allowing the membrane to move and adjust accordingly. In areas prone to seismic activity, additional measures may be taken to reinforce the waterproofing system. These can include the use of specialized membranes that have higher elongation and recovery properties or the incorporation of reinforcement elements such as fabric or mesh to enhance the membrane's ability to handle movement. In summary, a waterproofing membrane is specifically designed to handle the movement of a building caused by settling or seismic activity. Its flexibility, elongation, and recovery properties, along with proper installation techniques, allow it to accommodate the building's movements while maintaining a watertight barrier.

- Q:Are waterproofing membranes resistant to extreme weather conditions?

- Waterproofing membranes, indeed, possess the capacity to withstand even the most severe weather conditions. Typically composed of robust substances like rubber, PVC, or modified bitumen, these membranes can endure the detrimental impacts of harsh weather elements including heavy precipitation, snowfall, powerful gusts, and extreme temperatures. Their design incorporates flexibility and strength, guaranteeing their ability to effectively safeguard structures from water infiltration, even in the most challenging climatic circumstances. Furthermore, manufacturers often treat waterproofing membranes with UV stabilizers to counteract potential damage resulting from prolonged exposure to the sun's rays. In summary, these membranes offer reliable and long-lasting defense against extreme weather conditions.

- Q:Can waterproofing membranes be used on utility vaults?

- Yes, waterproofing membranes can be used on utility vaults. They provide an effective barrier against water intrusion, protecting the vault and its contents from moisture damage. Waterproofing membranes help to maintain the structural integrity of the vault and ensure its long-term functionality.

- Q:Can a waterproofing membrane be used in residential buildings?

- Absolutely, residential buildings can indeed utilize a waterproofing membrane. In fact, it is highly advisable due to its ability to effectively block moisture, thus preventing any water-related harm or growth of mold. Areas in residential buildings that are prone to water exposure, such as basements, bathrooms, roofs, and balconies, commonly employ waterproofing membranes. These membranes are typically applied on either the exterior or interior surfaces, creating a protective layer that hinders water infiltration. Consequently, this aids in preserving the building's structural integrity, prolonging its lifespan, and augmenting the overall comfort and safety of its inhabitants. Therefore, incorporating a waterproofing membrane into residential buildings is a prudent investment for safeguarding against potential water-related complications.

- Q:Can a waterproofing membrane be applied to tiled surfaces?

- Certainly! A tiled surface can indeed receive the application of a waterproofing membrane. In reality, it is customary to utilize a waterproofing membrane beneath tiled surfaces, particularly in regions susceptible to moisture like bathrooms, showers, and kitchen backsplashes. The waterproofing membrane serves as a shield, thwarting water infiltration into the foundation, thereby safeguarding both the tiles and the underlying structure against water-related harm. Before applying the waterproofing membrane for best outcomes, it is crucial to ensure that the tiled surface is adequately prepared and devoid of any fissures or impairments.

- Q:Can a waterproofing membrane be exposed to extreme temperatures?

- In general, waterproofing membranes can handle extreme temperatures without any issue. These membranes are designed to endure a wide range of temperatures, including both high and low extremes. However, it's crucial to understand that the temperature limits and performance features may differ based on the membrane's type and brand. To ensure the membrane is suitable for the specific temperature conditions it will face, it is always recommended to consult the manufacturer's specifications and guidelines. Moreover, factors like UV exposure and thermal expansion/contraction should also be taken into account as they can impact the overall performance and lifespan of the waterproofing membrane in extreme temperature conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPDM Rubber Waterproofing Membrane Underground Leakage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords