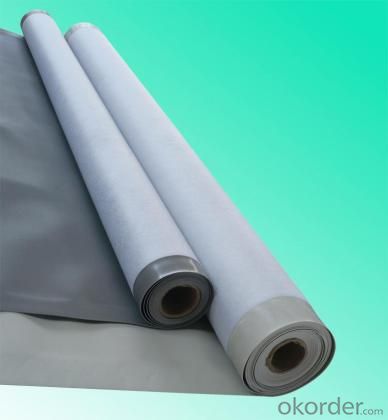

EPDM Rubber Sheet for Waterproofing Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduciton of EPDM Rubber Sheet for Waterproofing Industry:

This waterproof coiled material is of high elasticity with best performance among high polymer waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylenepropylene rubber of KINTOPbrand is produced with the use of the most advanced continuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,performances reach or exceed the demands of GB18173.1-2012 standard.

Features of EPDM Rubber Sheet for Waterproofing Industry:

Excellent weatherability, durability and size stability.

Good adaptability to high and low temperature, UV resistant and anti-corrosion.

High tensile strength and good elongation, accommodating substrate movement.

Easy installation, environment friendly.

Good rooting penetration resistance.

Service life up to 50 years.

Applications of EPDM Rubber Sheet for Waterproofing Industry:

Subways, tunnels, roofs, basement.

Industrial and civil building waterproofing, like water reservior, bridge, dam, etc.

Geosynthetic liner for swimming pool, channels, irrigation system

Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

Technical Data of EPDM Rubber Sheet for Waterproofing Industry:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

- Q:How does a waterproofing membrane handle exposure to chemicals?

- A waterproofing membrane is designed to provide protection against water and moisture, but its resistance to chemicals can vary depending on the specific type of membrane. Some waterproofing membranes are specifically formulated to withstand exposure to chemicals, while others may not be as resistant. Typically, a waterproofing membrane that is specifically designed to handle exposure to chemicals will have certain properties that make it more resistant. These properties may include a higher thickness, increased flexibility, and enhanced chemical resistance additives within the membrane. When a waterproofing membrane is exposed to chemicals, it should ideally be able to resist degradation, maintain its physical properties, and continue to provide effective waterproofing. However, it is important to consider that certain chemicals may still have an adverse effect on the membrane, especially if they are highly corrosive or reactive. To ensure the best performance in the face of chemical exposure, it is recommended to select a waterproofing membrane that is specifically designed to handle the types of chemicals it may come into contact with. It is also important to follow manufacturer guidelines for installation and maintenance to maximize the membrane's chemical resistance and overall lifespan. Regular inspections and maintenance are crucial to detect any signs of chemical damage or degradation on the waterproofing membrane. In cases where chemical exposure is expected to be significant, additional protective measures such as chemical-resistant coatings or overlays may be necessary to provide an extra layer of defense. In summary, the ability of a waterproofing membrane to handle exposure to chemicals depends on its specific formulation and design. Choosing a membrane with appropriate chemical resistance properties and implementing proper maintenance practices can help ensure its longevity and effectiveness in such environments.

- Q:Are there any drawbacks or limitations to using a waterproofing membrane?

- Using a waterproofing membrane comes with its fair share of drawbacks and limitations. One issue is the time-consuming and labor-intensive installation process. These membranes require careful surface preparation and multiple layers, which can be both time-consuming and require skilled labor. As a result, the overall cost of the project may increase. Another limitation is that not all surfaces are suitable for waterproofing membranes. Certain membranes are designed for specific types of substrates, such as concrete or metal, and may not adhere properly to other materials. To ensure proper adhesion and effectiveness, it is crucial to select the appropriate type of membrane for the specific surface. Moreover, waterproofing membranes can be sensitive to environmental conditions. Exposure to extreme temperature fluctuations, UV rays, and chemicals can degrade the membrane over time, reducing its effectiveness. To ensure the longevity of the membrane, regular inspections and maintenance may be necessary. Furthermore, during installation or due to external factors such as foot traffic or heavy objects, waterproofing membranes can be susceptible to damage. Punctures, tears, or improper installation can compromise the integrity of the membrane and reduce its ability to prevent water infiltration. Lastly, in certain situations, waterproofing membranes may not completely prevent water penetration. If there are existing cracks or structural issues in the substrate, water may find a way to seep through, bypassing the membrane. Therefore, it is important to address any underlying structural issues before applying the membrane to ensure optimal performance. In conclusion, while waterproofing membranes offer significant benefits in terms of water damage protection, it is crucial to consider these limitations and drawbacks before deciding to use them in specific applications.

- Q:Are waterproofing membranes resistant to alkalis?

- Yes, waterproofing membranes are generally resistant to alkalis.

- Q:Are waterproofing membranes resistant to saltwater?

- Yes, waterproofing membranes are generally resistant to saltwater. These membranes are designed to create a barrier that prevents water from penetrating through surfaces such as roofs, walls, or foundations. They are made from materials like rubber, polyethylene, or PVC, which are inherently resistant to the corrosive effects of saltwater. This resistance allows waterproofing membranes to effectively protect structures and surfaces from water damage, even in saltwater environments. However, it is essential to choose a waterproofing membrane specifically designed for saltwater applications to ensure optimal performance and longevity.

- Q:Can a waterproofing membrane protect against mold or mildew growth?

- A waterproofing membrane is capable of protecting against the growth of mold or mildew, as they thrive in environments that are damp and moist. The membrane acts as a barrier, preventing water from entering the building structure. This effectively keeps the area dry and greatly reduces the likelihood of mold or mildew growth. Furthermore, waterproofing membranes often contain anti-microbial properties that further hinder the growth of mold and mildew. Nevertheless, it is important to remember that while a waterproofing membrane can offer substantial protection against mold and mildew, it is not a foolproof solution. It is crucial to ensure proper ventilation and carry out regular maintenance to prevent these issues.

- Q:Can a waterproofing membrane be used on plywood surfaces?

- Yes, a waterproofing membrane can be used on plywood surfaces. Plywood is a commonly used material for construction, including outdoor projects such as decks and balconies. However, plywood is not naturally waterproof and can be susceptible to moisture damage over time. To protect plywood surfaces from water damage, a waterproofing membrane can be applied. This membrane acts as a barrier, preventing water from seeping into the plywood and causing rot or decay. There are various types of waterproofing membranes available, including liquid-applied membranes, sheet membranes, and peel-and-stick membranes. These membranes are designed to adhere to the surface of the plywood and create a watertight seal. It is important to follow the manufacturer's instructions for proper application and ensure that the plywood surface is clean and dry before applying the membrane. By using a waterproofing membrane, plywood surfaces can be effectively protected from water damage, extending their lifespan and maintaining their structural integrity.

- Q:Can a waterproofing membrane be used in steam rooms?

- Yes, a waterproofing membrane can be used in steam rooms. Steam rooms generate high levels of moisture and heat, which can cause damage to the walls and floors. A waterproofing membrane creates a barrier that prevents moisture from seeping through and protects the underlying structure. It is essential to choose a membrane specifically designed for steam room application to ensure proper performance and durability.

- Q:Are waterproofing membranes resistant to earthquake-induced water pressure?

- Waterproofing membranes can provide some level of resistance to earthquake-induced water pressure, but their effectiveness may vary depending on the specific membrane and the magnitude of the earthquake. Waterproofing membranes are designed to create a barrier against water infiltration, protecting the structure from water damage. However, they are not specifically designed to withstand the pressure caused by earthquakes. During an earthquake, the ground can experience significant shaking and movement, which can result in increased water pressure in the surrounding soil and groundwater. This increased pressure can potentially cause water to seep through the waterproofing membrane, compromising its effectiveness. To enhance the resistance of waterproofing membranes to earthquake-induced water pressure, additional measures may be required. These can include reinforcing the membrane with materials that can absorb shock and movement, installing drainage systems to alleviate excessive water pressure, and ensuring proper installation and maintenance of the membrane. It is important to consult with a professional waterproofing expert or structural engineer to determine the most suitable waterproofing system for earthquake-prone areas. They can provide guidance on selecting membranes that are specifically designed to withstand higher water pressure and offer better protection against earthquakes.

- Q:Can a waterproofing membrane be used in steam rooms?

- Yes, a waterproofing membrane can be used in steam rooms. A waterproofing membrane is designed to prevent water infiltration and is commonly used in areas where moisture is present, such as bathrooms, showers, and steam rooms. The membrane acts as a barrier, preventing water vapor from penetrating the underlying structure and causing damage. In steam rooms, where high levels of humidity and moisture are present, using a waterproofing membrane is essential to protect the walls, floors, and other surfaces from water damage and mold growth. It is important to choose a waterproofing membrane that is specifically designed for high moisture environments like steam rooms to ensure proper protection and longevity. Additionally, proper installation and adherence to manufacturer guidelines are crucial for the effectiveness and durability of the waterproofing membrane in a steam room setting.

- Q:Can waterproofing membranes be used on stormwater management systems?

- Indeed, stormwater management systems can benefit from the application of waterproofing membranes. These membranes are frequently utilized to safeguard structures against water infiltration and potential water-related harm. In the case of stormwater management systems, which are designed to collect, retain, and efficiently handle rainwater runoff, waterproofing membranes can be employed to establish a completely watertight seal, thereby averting leaks and seepage. Stormwater management systems often incorporate various components, such as retention ponds, infiltration basins, or underground storage systems. These elements must be adequately sealed to ensure the proper containment and effective management of the collected stormwater. When properly installed, waterproofing membranes serve as an impermeable barrier, effectively preventing water from escaping or infiltrating the system. The utilization of waterproofing membranes on stormwater management systems offers numerous advantages. Firstly, it helps to maintain the system's integrity and functionality by preventing leaks or seepage that could compromise its performance. This ensures that the stormwater is efficiently captured and managed, minimizing the risk of flooding or erosion. Furthermore, waterproofing membranes can significantly prolong the lifespan of stormwater management systems by safeguarding them against water damage. Water infiltration can lead to structural degradation, corrosion, or the proliferation of mold and mildew, all of which weaken the system over time. By establishing a waterproof barrier, these membranes contribute to the preservation of the structural integrity of the components, thus increasing their longevity and reducing maintenance requirements. Moreover, the use of waterproofing membranes on stormwater management systems also contributes to environmental sustainability. By effectively containing and managing stormwater runoff, these systems aid in reducing water pollution and enhancing the quality of natural water bodies. Waterproofing membranes play a vital role in preventing stormwater from carrying pollutants, such as chemicals or sediment, into rivers, lakes, or oceans. In conclusion, waterproofing membranes can be effectively utilized on stormwater management systems to establish a watertight seal, prevent leaks, and protect the components from water damage. By providing an impermeable barrier, these membranes help to maintain the system's functionality and integrity, prolong its lifespan, and contribute to environmental sustainability by reducing water pollution.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPDM Rubber Sheet for Waterproofing Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords