EPDM Pond Liner/Roofing Membrane Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Specification for EPDM Waterproof Membrane:

There are two installation ways.one is full sticking,the other is hot welding.

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

2.Product Technicial Data for EPDM Waterproof Membrane:

No. | Item | Technical index | ||

JL1 | JF1 | |||

1 | Tensile strength at break Mpa | Normal temperature≥ | 7.5 | 4.0 |

60°C≥ | 2.3 | 0.8 | ||

2 | Elogation at break | Normal temperature≥ | 450 | 400 |

-20°C≥ | 200 | 200 | ||

3 | Tearing strength KN/m≥ | 25 | 18 | |

4 | Impermeability 30minutes No leak | 0.3Mpa | 0.3Mpa | |

5 | Low temperature flexibility °C≤ | -40 | -30 | |

6 | Heat air ageing 80°C x 168h | Tensile strength retention rate % ≥ | 80 | 90 |

Elogation retention rate % ≥ | 70 | 70 | ||

Apperance of 100% elogation | no crack | no crack | ||

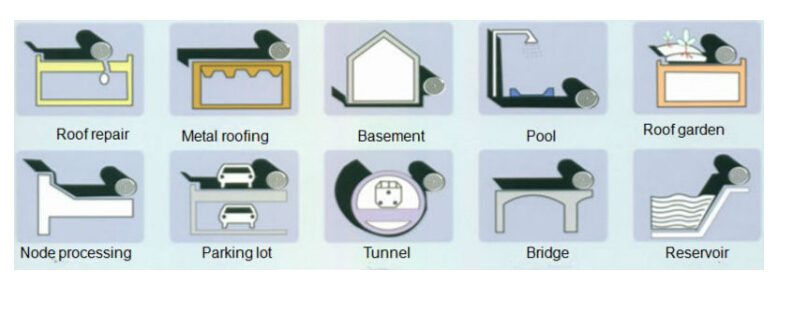

3. Product Application:

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation

4. Some photos:

- Q:Are there any limitations to using a waterproofing membrane?

- There exist certain limitations when using a waterproofing membrane. To begin with, although waterproofing membranes are successful in preventing water penetration, they do not always serve as a solution for structural problems that may result in leaks. In the presence of underlying issues with the structure, such as cracks or gaps in the foundation or walls, solely relying on a waterproofing membrane may not sufficiently address the problem. Furthermore, the installation of a waterproofing membrane necessitates thorough surface preparation, which can be time-consuming and expensive. The surface must be meticulously cleaned, dried, and cleared of any debris or contaminants for the membrane to adhere properly. Inadequate surface preparation may lead to improper adherence of the membrane, potentially causing it to fail in providing effective waterproofing. Moreover, waterproofing membranes are prone to damage during installation or afterwards if not adequately maintained. The membrane can be punctured or torn by sharp objects or heavy equipment, thereby compromising its effectiveness. Regular inspections and maintenance are imperative to ensure the membrane remains intact and in good condition. Additionally, waterproofing membranes have a limited lifespan and can deteriorate over time. Exposure to UV radiation, extreme temperatures, or harsh chemicals can degrade the membrane, reducing its ability to prevent water penetration. Regular inspections and potential replacement may be necessary to uphold the integrity of the waterproofing. Lastly, not all structures or environments are suitable for waterproofing membranes. Certain membranes may not be compatible with specific substrates or may not withstand high hydrostatic pressure. It is crucial to consult a professional and select the appropriate membrane type for the specific project and conditions. In conclusion, while waterproofing membranes can effectively safeguard structures from water damage, it is essential to acknowledge their limitations and ensure correct installation and maintenance to optimize their performance.

- Q:Are there any specific building code requirements for waterproofing membranes?

- Waterproofing membranes are subject to specific building code requirements. These requirements vary depending on the jurisdiction, but most codes mandate that waterproofing membranes meet certain standards and specifications. The purpose of these requirements is to protect buildings from water damage and maintain the safety and integrity of the structure. Some typical building code requirements for waterproofing membranes include: 1. Material standards: The building code may stipulate the type of materials that are permissible for waterproofing membranes. This can include specifications for the membrane's type, such as liquid-applied or sheet membranes, as well as requirements for thickness and composition. 2. Installation standards: The building code may provide specific instructions and techniques for installing waterproofing membranes. This can include requirements for appropriate surface preparation, application procedures, and details concerning penetrations and transitions. 3. Testing and certification: Building codes may mandate that waterproofing membranes undergo certain tests and meet specific performance criteria. This can include tests for water penetration resistance, durability, and compatibility with other building materials. In some cases, the code may require certification from a recognized testing laboratory. 4. Code compliance documentation: Building codes often demand that waterproofing membranes be installed in accordance with approved plans and specifications. This means that contractors may need to submit documentation to demonstrate compliance with the code, such as product data sheets, manufacturer's installation instructions, and details of the proposed waterproofing system. It is crucial to consult the local building code or regulatory authority to ascertain the specific requirements for waterproofing membranes in a particular jurisdiction. Complying with these requirements is vital to ensure the proper functioning and longevity of the waterproofing system and to prevent issues like water intrusion, mold growth, and structural damage.

- Q:Can a waterproofing membrane be used for schools or universities?

- Certainly, schools or universities can definitely utilize a waterproofing membrane. In fact, these membranes are widely employed in various construction projects, including educational institutions, to safeguard the building from water damage. They are typically applied to the outer surfaces of the structure, such as roofs, walls, or foundations, in order to establish a barrier that prevents water infiltration. By implementing a waterproofing membrane, schools and universities can ensure that their buildings remain dry and free from water-related issues such as leaks, mold growth, or structural damage. This not only helps to maintain the integrity and longevity of the building, but also provides a secure and comfortable environment for students, staff, and visitors. Moreover, waterproofing membranes can also be utilized in areas such as bathrooms or wet laboratories to hinder water seepage, which is particularly crucial in educational settings where heavy foot traffic and frequent water usage are common. All in all, integrating a waterproofing membrane in schools or universities is a proactive measure to safeguard the infrastructure, enhance durability, and foster a conducive learning environment.

- Q:Does a waterproofing membrane have any impact on the appearance of a surface?

- The appearance of a surface can be affected by a waterproofing membrane. When it is applied to a wall or floor, the membrane acts as a barrier to prevent water or moisture from entering. This process typically involves adding a coating or layer that can change the texture or shine of the surface. Occasionally, the membrane might result in a slight color variation or darken the surface. Nevertheless, there are transparent or colorless waterproofing membranes accessible that have minimal impact on the appearance of the surface. Ultimately, the extent to which the appearance is influenced depends on the specific type of waterproofing membrane utilized and the desired aesthetic result.

- Q:Can a waterproofing membrane be used for a planter box waterproofing?

- Planter box waterproofing can be achieved by utilizing a waterproofing membrane. This specific type of membrane is designed to establish a barrier against water and moisture, effectively prohibiting their penetration through the surface it is applied on. Consequently, it serves as an excellent option for safeguarding the integrity of the planter box and preventing water-related harm. By applying the membrane to the interior of the box, a tight seal is formed, effectively preventing water leakage and damage to surrounding surfaces. Furthermore, the utilization of a waterproofing membrane aids in prolonging the lifespan of the planter box by curbing the growth of mold or mildew, which can be triggered by excessive moisture. In conclusion, opting for a waterproofing membrane for planter box waterproofing is a pragmatic and efficient approach to ensure the long-lasting durability of the structure.

- Q:Can a waterproofing membrane be used in high-rise buildings?

- Yes, a waterproofing membrane can be used in high-rise buildings. In fact, it is highly recommended to incorporate a waterproofing system in high-rise buildings to protect them from the damaging effects of water infiltration. Waterproofing membranes are designed to provide a barrier against water ingress, preventing leaks and moisture damage to the structure. They are commonly used on roofs, basements, foundations, and other areas that are exposed to water or moisture. The selection of the appropriate waterproofing membrane will depend on various factors such as the specific building design, construction materials, and environmental conditions. It is important to consult with experienced waterproofing professionals to determine the most suitable membrane system for a high-rise building to ensure long-term protection against water-related issues.

- Q:Is a waterproofing membrane resistant to root penetration?

- Yes, a waterproofing membrane is typically resistant to root penetration. Waterproofing membranes are designed to create a barrier that prevents water from seeping through and damaging the underlying structures. These membranes are typically made of materials such as modified bitumen, PVC or EPDM, which are highly durable and resistant to root penetration. Additionally, some membranes are specifically manufactured with root-resistant properties to provide an added layer of protection against potential root damage. Root-resistant waterproofing membranes typically contain additives that deter root growth or have a thicker and more robust composition that can withstand root penetration. However, it is important to note that while waterproofing membranes are generally effective in preventing root penetration, they should be installed correctly and regularly inspected to ensure their integrity over time.

- Q:Does a waterproofing membrane affect the structural integrity of a building?

- No, a waterproofing membrane does not affect the structural integrity of a building. Its primary function is to prevent water penetration and protect the building from moisture damage, without compromising the overall strength or stability of the structure.

- Q:Can a waterproofing membrane be used for underground parking garages?

- Yes, a waterproofing membrane can be used effectively for underground parking garages. These membranes are specifically designed to provide a protective barrier against water infiltration, preventing damage to the structure and ensuring a dry and safe environment for vehicles.

- Q:Are waterproofing membranes resistant to mineral oils?

- Yes, waterproofing membranes are generally resistant to mineral oils.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPDM Pond Liner/Roofing Membrane Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords