EP/NN/CC Rubber Conveyor Belt Industry Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

EP/NN/CC Rubber Conveyor Belt Industry Conveyor Belt

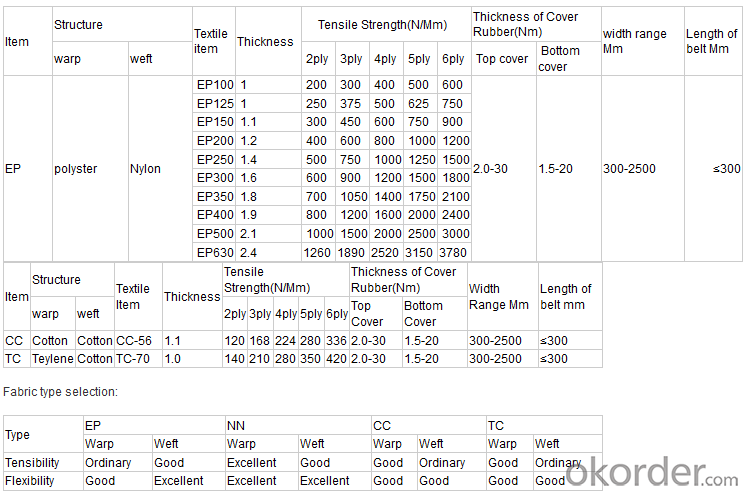

Specification of Rubber Conveyor Belt

1) Fabric: Cotton, Nylon, Polyester

2) Width: 200mm-1800mm

3) Thickness: 4mm-20mm

4) T/S: 8Mpa-24Mpa

USAGE: mining, metallurgical industry and architectural industry, ports etc.

Pls contact me freely if any inquiry or questions,thank you!

- Q:What's the difference between rubber and silicone?

- Different types and grades of rubber applications are not the same, such as natural rubber is mainly used to make tires, butyl rubber mainly in the tube, three yuan ethylene propylene rubber for sealing products.

- Q:What does the rubber tire do to people?

- Rubber is divided into natural rubber and synthetic rubber according to its raw material. According to the form is divided into block rubber, latex, liquid rubber and rubber powder. Latex as a rubber colloidal water dispersion; liquid rubber as an oligomer of rubber, not before the vulcanization is generally viscous liquid; powder rubber is the latex processing into powder, in order to benefit ingredients and processing. Thermoplastic rubber, developed in 1960s, does not require chemical vulcanization and is shaped by thermoplastic processing. Rubber according to the use of divided into general and special type of two categories. It is not easy to insulator, conductive, but if water or different temperature, are likely to become a conductor. Conduction is the conduction of electrons in a substance, molecule, or ion.

- Q:How to maintain and store the rubber material?

- Rubber itself is a shelf-life, you can ask the supplier to warranty, above all, as fillers, such as calcium carbonate, carbon black, long time no problem, also have a shelf life of antioxidant promoter, especially individual species. When storing, pay attention to fire prevention, moisture-proof, away from the high temperature, avoid direct sunlight, of course, the general "first in first out" is a must follow the truth.

- Q:How do you remove the rubber on your new slippers?

- Different types of rubber deodorant by different chemical AO and effect, can effectively remove all kinds of rubber, including all kinds of recycled rubber smell in the processing and use of rubber products, improve the level of environmental protection, applicable to all kinds of rubber molding process. The use of low odor, high efficiency, safe and non-toxic, by Ma'anshan Keli chemical technology development and production company.

- Q:How are rubber wires processed?

- In the production of rubber products, vulcanization is the last process.Vulcanization is a crosslinking process in which rubber molecules change from linear structure to network structure under certain conditions. Curing methods are cold vulcanization, room temperature vulcanization and heat vulcanizing three kinds. Most rubber products are vulcanized by heat. Hot vulcanizing equipment, vulcanizing pot, flat vulcanizing machine, etc.. Rubber wires and cables are vulcanized by continuous hot air.

- Q:Bought a mouse pad, a little rubber, how to remove?

- Rubber deodorant can effectively reduce or eliminate the odor or odor caused by rubber additives and rubber residual monomers in rubber products. It is especially suitable for some rubber products which use two times to reprocess and reprocess. The rubber deodorant has excellent temperature resistance, long aging and small amount of addition. It does not affect the performance of the rubber products which need to be covered or flavored.

- Q:What adhesive does rubber and wood have better glue?

- Glue is the intermediate between two kinds of materials. It is a kind of fine chemical, which is mainly made of sticky material, physical form, hardening method and classified material. There is a common instant glue (502 common ethyl cyanoacrylate adhesive is a powerful instant), epoxy resin adhesive, anaerobic glue, UV glue (UV curing), hot melt adhesive, pressure-sensitive adhesive, latex etc..

- Q:What gum does rubber and metal stick together?

- The cohesion of JL-518 silicone rubber heat vulcanization glue: is a new high performance silicone primer. For the bonding of silicone rubber, TPU and aluminum, iron, copper, stainless steel and other metal nylon cloth special adhesive, in particular for the preparation of silicone rubber rollers and composite rubber products, its performance is better than other similar products, the role of shear bonding surface can withstand long time twist extrusion stress. The preparation of ordinary rubber rolls and compound rubber products such as ethylene propylene rubber also has good effect. Non-toxic, no harmful solvents, comply with environmental protection requirements, no adverse effects on human health.

- Q:For the application of common synthetic rubber, not too long or too difficult, want to do

- Chloroprene rubber (CR) by chloroprene do monomer emulsion polymerization and into the polymer. This rubber molecule containing chlorine atom, so compared with other general rubber: it has excellent oxidation resistance, ozone resistance, non flammable, after the fire can be self extinguishing, the advantages of oil resistance, solvent resistance, acid and alkali aging resistance, good air tightness; the mechanical performance is better than natural rubber, it can be used for general rubber, also can be used for special rubber. The main disadvantage is poor cold resistance, large proportion, relatively high cost, good electrical insulation, processing is easy to stick rolling, easy to scorch and easy sticking. In addition, rubber poor stability, not easy to save. The temperature range of about - 45 DEG C ~ + 100 DEG C. Mainly used in the manufacture of anti ozone aging resistance, high cable sheath and various protective cover, protective cover; oil resistance, chemical corrosion resistance of hose, adhesive tape and chemical lining Flame resistant underground mining rubber products, as well as a variety of molded products, seals, mats, adhesives and so on

- Q:What advantage does ethylene propylene rubber with three yuan compare to two yuan ethylene propylene rubber?

- In recent years, the third monomer and new technology development, foreign developed 1 7- octadienoic, 6, 5, two 10- methyl -1, 9- eleven, 7- two three ene 3, methyl -1, 6- octadienoic, 5 7-, two methyl -1, 6- octadienoic, 7- methyl -1, 6- octadiene as the three EPDM third monomer, the performance of three Yuan rubber has been enhanced. The monomer and content of third monomer in three yuan ethylene propylene rubber have direct influence on vulcanization rate and vulcanizate property. Among them, dicyclopentadiene (DCPD) as the third monomer, although the price is low, but the three Yuan rubber vulcanization speed is slow, difficult and high degree of unsaturation diene rubber and use; to ethyiidenenorbomene (ENB), 6 10-, two methyl -1, 5, third monomer three Yuan rubber vulcanization speed 9- eleven three ene as fast, the former has become the main varieties of three yuan of ethylene propylene rubber. The third monomer content in iodine said three EPDM iodine value is generally 6-30, mostly around 15. The iodine value is 6-10, curing speed is slow, difficult and high unsaturated rubber; iodine value is 25-30, for ultra high speed curing type, available in any proportion and high unsaturated diene rubber and use. Therefore, three yuan ethylene propylene rubber and other rubber in use, should pay attention to choose the appropriate three yuan ethylene propylene rubber varieties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EP/NN/CC Rubber Conveyor Belt Industry Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords