Environmental Friendly Halogen Free Flame Retardant Nylon Jacket Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nylon compound:

1. Competitive price

2. Customized products

3. Stable quality

4. 30 years of experience

Nylon compound:

1. Applications of Nylon compound:

Used as special jacket for railway, locomotive, and communication optical cables etc, of which operation temperature is at 125 degree C.

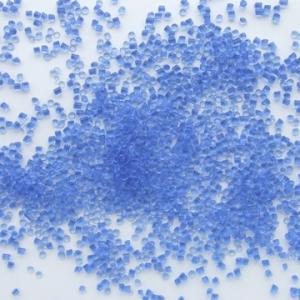

2. Descriptionof Nylon compound:

Safe environmental friendly flame retardant nylon jacket compound, based on nylon resin, is produced and pelletized by special technology with adding special modifier, flame retardant, anti-oxidant and other special additives.

3. Processing of Nylon compound:

The compound can be processed with conventional extruders. The L/D should be greater than or equal to 25; and the compression ratio of screw should be greater than 1:2.5.

The following temperature(°C) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

temperature °C | 220 | 240 | 245 | 245 | 240 | 240 |

Note:Compound should be dried at 100°C before use, if it was stored more than one months.

4. Storage and transport of Nylon compound:

Packaging:25kg/bag,Aluminum foil and PE membrane inside bag, and kraft outside bag.

Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be in clean, cool, dry, and ventilated conditions.

5. Properties of Nylon compound:

Item | Unit | PA5001 | PA4001 | ||

Standard | Typical | Standard | Typical | ||

Density | g/cm3 | -- | 1.22 | -- | 1.25 |

Hardness | Shore D | -- | 68 | -- | 68 |

Tensile Strength | ≥MPa | 30 | 62 | 30 | 60 |

Elongation at Break | ≥ % | 200 | 260 | 200 | 250 |

Thermal Aging | °C×h | 158×168 | 158×168 | ||

TS/EB Retention | ≥ % | 75/75 | 90/85 | 75/75 | 90/88 |

Oil resistant test Immersion in ASTM2# | °C×h | 100×70 | 100×70 | ||

TS/EB Retention | ≥ % | 40/40 | 23/27 | 40/40 | 24/28 |

Volume Resistivity, at 20°C | ≥Ω*m | 1.0×1012 | 1.1×1013 | 1.0×1012 | 2.3×1013 |

Oxygen Index | ≥ | 28 | 30 | 28 | 31 |

Low temperature winding | -40 | -50 | -40 | -50 | |

Dielectric strength | MV/m | --- | 24 | --- | 24 |

UL Class flame retardant | --- | VW-1 | --- | VW-1 | |

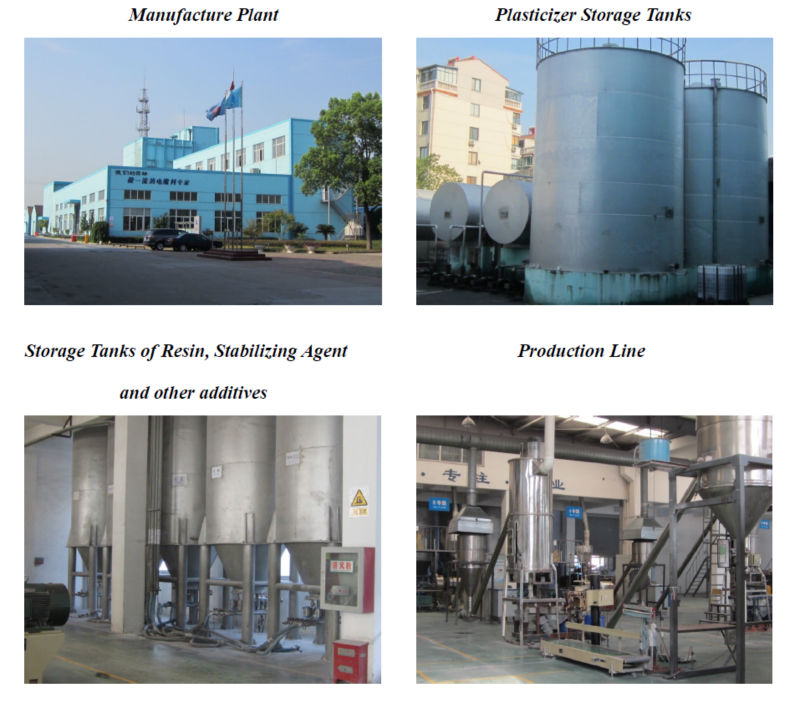

6. Company

- Q:I do PA, PC, PP and other plastic raw materials can be used in the eye frame and lens it

- There are PC lensesThe PC material is more impact resistant than polymer resin, often used in aviation equipment transparent windows, police on the mask, and the astronaut's helmet mask, it is only about 1/10 the weight of glass, resin lenses compared with traditional is only half of the weight.

- Q:How many kinds of plastic do you have?

- A. reinforced plastic:Plastic material can be divided into granular (such as calcium plastic reinforced plastic), fiber (such as glass fiber or glass cloth reinforced plastic), sheet (such as mica reinforced plastic) three. According to the material can be divided into cloth reinforced plastic (such as rags or reinforced asbestos reinforced plastics), inorganic mineral filled plastics (such as quartz or mica filled plastics), fiber reinforced plastics (such as carbon fiber reinforced plastics) three

- Q:What is the plastic basin made of?

- The raw material is PP and PE, the raw material price is more than 10000, and some can be recycled at around 5000.

- Q:PE plastic bellows raw material formula (PE and PP ratio, as well as other filling)?

- PE bellows formulations generally include the main resin, additives and fillers, in which the resin polymer in the infrared spectrum of the difference, the plastic material can be judged by analysis.

- Q:Will plastic raw materials (such as PET, PP, etc.) be made of non-woven fabrics, will certainly contain BPA?

- Only PC (polycarbonate) is available.If the customer is not sure, you can take your product to the third party organization testing, prove that you can do without BPA, and ask your supplier to provide inspection reports and guarantee without BPA.

- Q:What can be added to the PP plastic material to prevent light transmission?

- PP material suppliers to remind you, PP plastic raw materials to add sunscreen, adding black masterbatch or impact PP raw materials on the line

- Q:How are plastic products made? What is the raw material of plastics?

- Plastic products are divided into: injection molding, blow molding, spray molding, blister, and die casting. Plastic material is oil. It must be done at a high temperature. The mold you call is usually steel.

- Q:Chemical, plastic raw materials, plastic raw materials how sub grade?

- That's because the raw material used for making plastic barrels is different. Just like the quality of the clothes, the grades of the fabrics used are different, and the products presented are definitely different.

- Q:How many kinds of raw materials are there for blowing plastic bottles?

- Plastic bottles are made of polyethylene or polypropylene and added a variety of organic solvents. Plastic bottles are widely used in polyester (PET), polyethylene (PE), polypropylene (PP) as raw material, add the corresponding organic solvent after high-temperature heating, the plastic mold by blow molding, extrusion blow or injection molding of plastic containers.

- Q:What is the difference between PPA plastic raw material and PP?

- PP is the most common bulk material, such as you see the plastic basin, storage box, etc., is PP do, PP's scientific name is polypropylene, regular PP price is now a little more than ten thousand per ton, special modified PP price is slightly expensive.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Environmental Friendly Halogen Free Flame Retardant Nylon Jacket Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products