End Suction Water Pump for Water Circulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

End Suction Centrifugal Pump

1.Structure of End Suction Centrifugal Pump Description

End Suction Centrifugal Pump complies fully to the European Standard BS EN733 / DIN24255 of performance and dimensions. They are used for pumping clean water or liquids similar to water, achieving wide application on plants, mines, city water supplies, air-conditioning coolers, firefighting system and irrigation. Pumps of the same model have different performance levels basing on different diameter after impeller trimming. Overall the whole series, there are only four sizes of shaft and five of bearing housing. As long as their bearing housings are of the same size, different pumps can interchange chief parts such as shaft, shaft sleeve, shaft seal, impeller nut, etc.

End Suction Centrifugal Pump is also very easy to be installed and maintained. Back pull-out design, driven through flexible coupling, so that pump casing and motor can remain in position while other spare parts are removed.

2.Main Features of the End Suction Water Pump

• very easy to be installed and maintained

•Back pull-out design

•Driven through flexible coupling

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

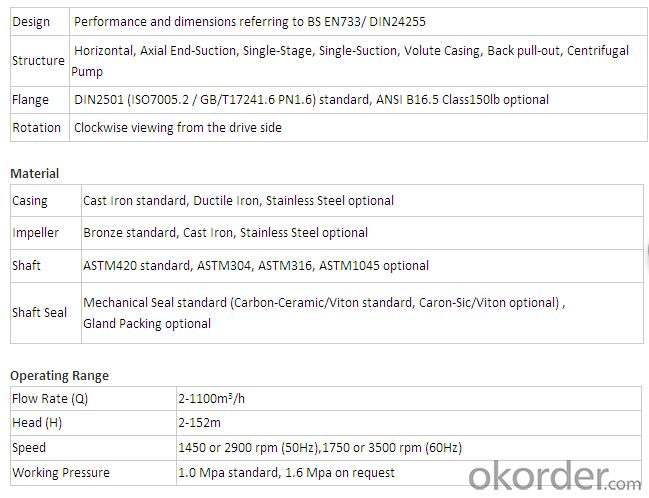

3.End Suction Water Pump Specification

4.Picture of End Suction Pump

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q:If the water pump does not get water to pump, will it be burnt out? If so, then can it be fixed? And if it doesnt get water to pump, what exactly happens to it?

- Anything can be fixed. The question is: is it cheaper to repair or replace the water pump? Keep in mind that water through a pump cools it. Without this water, the pump will overheat and eventually fail.

- Q:its a honda accord 1991 Lx my car started overheating only when i stop when i go it doesnt overheat what should i check like the water pump

- chances are your radiator cooling fan is not working,could be the cooling fan switch,bad fan motor,or relay

- Q:What is the relationship between pump power, lift and flow?

- N= QH/1000 gamma ETA gamma, severe liquid, cattle - ETA / m3; efficiency; N- kW; H- head, power meters;Q- volume flow per cubic meter / sec.

- Q:someone told me my water pump may be going out and it sounds like their is a loose barron inside of it, so how much is it and and if i was to have someone else to fix it how much will it cost me

- type okorder type in your info and look for a how to tyhey have many there an dother guy layed it out pretty well

- Q:There is a loud squeecking noise coming from the water pump and the serpentime belt isnt loose!I dont know how long it would take a mechanic to do the job?

- Spray some water on the belt while it's schreeching to rule the belt out. They often make noise, even when tight.

- Q:How hard is it change a 1993 subaru imprezza water pump

- hi Silicone wont do it, keep in mind the rad cap says 15lb. On my truck there's a center gasket and it leaked out the backside. So it probable has to return out. or possibly a bolt got here out?

- Q:What is called soft start of water pump?

- Soft start has many methods, mainly used in high-power motor.Through soft starter, or frequency conversion start, or star triangle start to achieve.It means that it starts at a slower pace.

- Q:QDX is a submersible pump. What does "X" mean?

- QDX is a submersible pump model, its specific meaning is:1.Q: submersible pump.2.D: single-phase power supply, three-phase electricity is not marked.3.X: pump, pump type is not marked.Complete submersible pump model will generally add rated flow, rated lift and motor power rating. For example: QDX40-8-1.5, meaning with single-phase 1.5KW motor, rated flow of 40 cubic meters / time, the rated lift of 8 meters under the pump submersible pump.According to the different relative position of pump and motor, submersible pump is divided into pump type and pump type. The pump submersible pump motor in the above, below, this structure greatly reduces the radial size of the pump, so much for submersible pump and small submersible pump operation. Submersible pump submersible pump on top of the pump in the following, it is divided into two types of internal and external type. The submersible pump carries the liquid through the annular flow passage around the motor, then cools the motor and then flows out of the pump outlet. Even though the pump is near the drain sump, there is no need to worry about the temperature rise of the motor, so the application is becoming wider and wider. External pump submersible pump directly from the pressurized water chamber after the impeller or diffuser outlet of discharged liquid, motor is cooled by liquid pumping. As the lower pump structure can work in a relatively shallow liquid, it is often used in submersible pumps for operating surfaces, especially the main structure of large caliber submersible pumps.

- Q:i am not sure whether the water pump is bad or how much water should come out of exhaust.

- take it in.

- Q:I have a leak coming from the water pump that flows down on the side of the AC compressor before landing on the ground. I cannot verify exactly where the leak is coming from on the pump, but I am sure it is the pump leaking because it also sounds bad like rattling. My question is do I have to remove any other components, such as the AC compressor to be able to remove the water pump. I would be great full for any suggestions.Regards,Steph

- First you have to mention which E320 you have. It could be either a gasoline or diesel model and the E320 model designation has had the M104 I6, M112 V6, M613 I6 diesel, and M642 V6 diesel under the hood. The water pump is not located in the same place on all engines.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

End Suction Water Pump for Water Circulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords