EN AW - 5052 PE Prepainted Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of EN AW - 5052 PE Prepainted Aluminium Composite Panel

EN AW - 5052 PE Prepainted Aluminium Composite Panel is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 5052 PE Prepainted Aluminium Composite Panel

EN AW - 5052 PE Prepainted Aluminium Composite Panel | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 5052 PE Prepainted Aluminium Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 5052 PE Prepainted Aluminium Composite Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 5052 PE Prepainted Aluminium Composite Panel

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

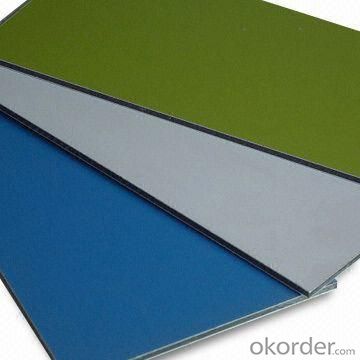

6. Image of EN AW - 5052 PE Prepainted Aluminium Composite Panel

7. Package and shipping of EN AW - 5052 PE Prepainted Aluminium Composite Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum coils be used in electrical or electronic applications?

- Yes, aluminum coils can be used in electrical or electronic applications. Aluminum is a highly conductive material and has several advantages over other materials, such as copper, when it comes to coil applications. Aluminum coils are lightweight, which makes them suitable for applications where weight is a concern. They also have good thermal conductivity, allowing for efficient heat dissipation. Additionally, aluminum coils are corrosion-resistant, making them durable and suitable for outdoor or high-humidity environments. However, it is important to note that aluminum has a lower electrical conductivity compared to copper, so the design and dimensions of the coil need to be carefully considered to ensure optimal performance.

- Q:What are the different edge treatments available for aluminum coils?

- Aluminum coils offer a variety of edge treatments, each with its own benefits and uses. 1. Mill Finish: The aluminum coil remains as it is after manufacturing, without any additional treatment. This option is ideal for industrial or construction applications that prioritize functionality over aesthetics. 2. Trimmed Edge: The edges of the aluminum coil are carefully trimmed to remove sharp edges, ensuring safe handling and reducing the risk of injury during fabrication or installation. 3. Deburred Edge: Similar to the trimmed edge treatment, the deburred edge involves eliminating burrs and sharp edges from the coil's edges. This is important when the aluminum coil will come into contact with other materials or surfaces to prevent scratches or damage. 4. Rolled Edge: The edges of the aluminum coil are rolled to create a smooth, rounded edge. This not only enhances the coil's appearance but also provides additional protection against corrosion and damage. 5. Beveled Edge: An angled cut is made on the edges of the aluminum coil to achieve a sloping edge. This treatment is commonly used in architectural applications where a sleek and modern look is desired, and it also facilitates easier welding or joining of the coil. 6. Hemmed Edge: The edges of the aluminum coil are folded or bent to create a hem-like finish. This treatment adds strength and rigidity to the coil, making it suitable for applications that require durability or structural integrity. 7. Painted or Powder Coated Edge: The edges of the aluminum coil are painted or powder coated to match the color or finish of the rest of the coil. This is often done for applications where the coil's edges are visible, achieving a seamless and consistent appearance. Ultimately, the choice of edge treatment for aluminum coils depends on the specific needs of the application, considering both functionality and aesthetics.

- Q:How are aluminum coils protected against chemical exposure?

- Aluminum coils are protected against chemical exposure through a variety of methods. One common method is the application of a protective coating or finish on the surface of the coils. This coating acts as a barrier between the aluminum and any potentially harmful chemicals, preventing direct contact and corrosion. Another method is the use of anodization, which involves electrolytically treating the aluminum surface to create a layer of oxide. This oxide layer provides excellent resistance against chemical exposure and enhances the overall durability of the coils. Anodized aluminum coils are widely used in industries where chemical resistance is crucial, such as in construction, automotive, and aerospace applications. Furthermore, aluminum coils can be protected by using alloys that are specifically designed to resist chemical corrosion. These alloys contain additional elements, such as copper or magnesium, which enhance the aluminum's resistance to chemical attack. By carefully selecting the appropriate alloy composition, manufacturers can ensure that the aluminum coils are better able to withstand chemical exposure. Overall, the protection of aluminum coils against chemical exposure involves a combination of protective coatings, anodization, and the use of corrosion-resistant alloys. These measures help to extend the lifespan of the coils and maintain their performance even in harsh chemical environments.

- Q:How to sell the super hard 5083aluminum alloy and 5083 aluminum coil?

- Among the alloy which cannot endure heat treatment, 5083 aluminum alloy, a kind of high magnesium alloy, has the properties of intensity, machinability, anti-corrosion, electric-arc weldability and aesthetic after anodizing. The main element of 5083 alloy being magnesium, it is endowed with corrosion resistance, weldablility and moderate intensity, thus applicable to maritime areas such as ships, and cars, airplane weldments, metro light rail, and pressure vessel (such as liquid tank truck, refrigerated truck, refrigerated container), refrigerating equipment, television tower, drilling equipment, transport facility, missile parts, armor and so on.

- Q:How do aluminum coils impact energy efficiency?

- Aluminum coils play a vital role in enhancing energy efficiency across various applications, such as heating, ventilation, and air conditioning (HVAC) systems, refrigerators, and heat pumps. The outstanding heat transfer properties of aluminum are the primary reason for their positive impact on energy efficiency. The excellent heat conductivity of aluminum enables it to quickly absorb and release thermal energy. In HVAC systems, aluminum coils effectively transfer heat between the indoor and outdoor units. This efficient heat transfer reduces the system's workload, enabling it to operate more efficiently and consume less energy. Moreover, aluminum coils possess the advantages of being lightweight and having a large surface area, further enhancing their heat transfer capabilities. By reducing the overall weight of the system, their lightweight nature results in lower energy consumption. The increased surface area promotes better contact between the air and the coils, facilitating more effective heat exchange. Another benefit of aluminum coils is their resistance to corrosion, a common issue in HVAC systems. Corrosion can hinder the efficiency of heat transfer, leading to increased energy consumption. The corrosion resistance of aluminum coils ensures long-lasting performance, maintaining their efficiency and reducing the need for frequent maintenance or replacement. To summarize, aluminum coils significantly contribute to energy efficiency by facilitating efficient heat transfer, reducing the workload on HVAC systems, and minimizing energy consumption. Their lightweight nature, large surface area, and corrosion resistance further enhance their positive impact on energy efficiency.

- Q:Are aluminum coils suitable for high-pressure applications?

- High-pressure applications are generally not suitable for aluminum coils due to their low strength compared to metals like steel or copper. Despite being lightweight and corrosion-resistant, aluminum coils are prone to deformation or failure under high pressure. In order to withstand significant stress and ensure a robust system, materials with higher strength such as copper or stainless steel are commonly used in such applications. Nevertheless, it is crucial to refer to industry standards, guidelines, and specific requirements to determine the most suitable material for a particular high-pressure application.

- Q:Can aluminum coils be used in roofing or cladding systems?

- Indeed, roofing and cladding systems can make use of aluminum coils. The lightweight characteristic and exceptional resistance to corrosion make aluminum a favored option for these purposes. In order to produce a sturdy and enduring solution, it is commonplace to employ aluminum coils in roofing and cladding systems. These coils are frequently coated with a shielding layer or finishing touch to augment both performance and aesthetics. Additionally, the ease of working with aluminum coils ensures that installation and maintenance are hassle-free. In conclusion, aluminum coils prove to be a fitting choice for roofing or cladding systems, as they provide numerous benefits and fulfill the demands of these applications.

- Q:How do I deal with too much aluminum powder when the aluminum strips are divided?

- Because of low maintenance costs, the former favored by enterprises, accounting for more than 90% of all dust removal systems, but often there will be a problem: ventilation and dust removal system is not strictly in accordance with the specifications to do, resulting in dust accumulation.

- Q:How are aluminum coils used in the production of furniture and fixtures?

- Furniture and fixture production heavily relies on aluminum coils, which play a vital role in creating lightweight and long-lasting pieces. These coils are typically crafted from top-notch aluminum alloys, known for their exceptional strength-to-weight ratios and resistance to corrosion. One primary application of aluminum coils in furniture production involves constructing frames for chairs, tables, and other seating arrangements. Aluminum's lightweight nature simplifies handling and transportation, while still providing the necessary structural integrity. The coils can be easily molded, welded, and assembled into various frame designs, offering flexibility in creating different furniture styles. Furthermore, aluminum coils find frequent use in manufacturing fixtures like cabinets, shelves, and display racks. These coils can be cut, shaped, and bent to create customized components that perfectly suit specific design requirements. Aluminum's corrosion resistance ensures that these fixtures can endure exposure to moisture, making them suitable for both indoor and outdoor settings. Moreover, the utilization of aluminum coils in furniture and fixture manufacturing offers advantages that go beyond their physical properties. Aluminum is a highly recyclable material, making it an environmentally friendly choice. Its durability and low maintenance requirements also contribute to cost-effectiveness, reducing long-term expenses for manufacturers and consumers alike. To summarize, aluminum coils are indispensable in furniture and fixture production due to their lightweight, durable, and corrosion-resistant characteristics. Their versatility enables the creation of various designs, while their recyclability and cost-effectiveness make them a preferred choice in the industry.

- Q:How do aluminum coils compare to iron coils in terms of weight?

- In terms of weight, aluminum coils possess a significant advantage over iron coils due to their lower density. This results in aluminum coils weighing less for the same volume. With aluminum weighing approximately one-third of iron, it becomes a substantially lighter material when utilized in coil applications. This advantage in weight proves particularly advantageous in industries prioritizing weight reduction, such as automotive and aerospace, as it enhances fuel efficiency and overall performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EN AW - 5052 PE Prepainted Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords