EN AW - 2219 Aluminium Sheet With Transparent PE Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of EN AW - 2219 Aluminium Sheet With Transparent PE Film Description

EN AW - 2219 Aluminium Sheet With Transparent PE Film is one semi-finished aluminium material. This sheet can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 2219 Aluminium Sheet With Transparent PE Film

EN AW - 2219 Aluminium Sheet With Transparent PE Film | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 2219 Aluminium Sheet With Transparent PE Film

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 2219 Aluminium Sheet With Transparent PE Film

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 2219 Aluminium Sheet With Transparent PE Film

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

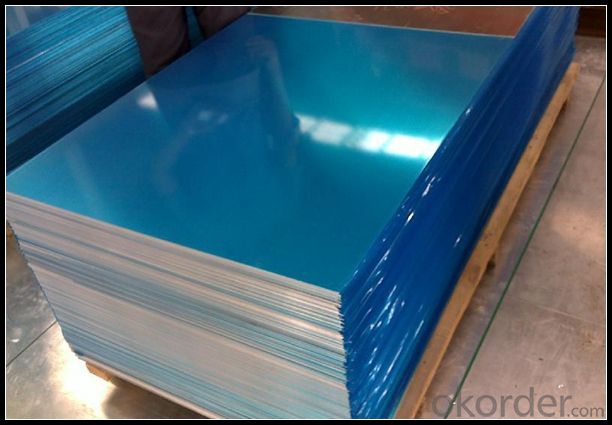

6. Image of EN AW - 2219 Aluminium Sheet With Transparent PE Film

7. Package and shipping of EN AW - 2219 Aluminium Sheet With Transparent PE Film

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:How do aluminum coils compare to other metals in terms of strength?

- Compared to numerous other metals, aluminum coils possess an exceptional strength-to-weight ratio. Although not as robust as steel, aluminum is both lighter and more pliable, rendering it a favored option in diverse applications. Aluminum coils are capable of enduring substantial forces without fracturing or distorting, thereby rendering them suitable for a broad array of industries, encompassing automotive, aerospace, and construction. Furthermore, these coils exhibit commendable resistance to corrosion, thereby bolstering their longevity and durability. However, it is crucial to acknowledge that the strength of aluminum may fluctuate depending on the chosen alloy and temper. Thus, specific comparisons ought to be conducted based on the particular application and stipulations.

- Q:I need ideas on soundproofing a 12' aluminum fishing boat?

- The ULTIMATE way to soundproof and line your boat is with that stuff they cover the bed of pick-up trucks. Cabelas sells a kit you paint on. It works great! Call Cabelas, it's only $50, and it works and looks professional!

- Q:Can aluminum coils be used in the aerospace industry?

- Indeed, the aerospace industry finds great utility in aluminum coils. The extensive use of aluminum in this sector is attributed to its advantageous characteristics, including its low density, impressive strength-to-weight ratio, and exceptional resistance to corrosion. The manufacturing of numerous aircraft elements, such as fuselage panels, wings, and structural frameworks, often relies on the employment of aluminum coils. These coils can be effortlessly molded into various shapes and sizes, allowing for design flexibility and a reduction in overall aircraft weight. Moreover, aluminum coils seamlessly integrate with diverse manufacturing techniques like welding, machining, and forming, rendering them a prime selection for the aerospace industry.

- Q:hey, my dad and i are working on painting our front door and the current piece of aluminum in front of it wont go with the new color. it doesnt look like it can be changed out so we are wondering, other than spray paint, what can you put on aluminum to make it turn permanently black. my dad mentioned gun blue, but that only works on steel. thanks

- Dad is on the right track....maybe. There are blackeners for aluminum you can get from gunshops. Used to touch up scratched or worn black anodized finish on aluminum gun parts. Never used it in large areas. Best regards

- Q:Can aluminum coils be used in aerospace heat exchangers?

- Yes, aluminum coils can be used in aerospace heat exchangers. Aluminum is widely used in aerospace applications due to its lightweight and excellent heat transfer properties. It offers good corrosion resistance, high thermal conductivity, and is cost-effective, making it a suitable material for heat exchangers used in aircraft and other aerospace systems.

- Q:Are aluminum coils fire-resistant?

- Yes, aluminum coils are fire-resistant.

- Q:What are the different coil slitting methods used for aluminum coils?

- There are several coil slitting methods used for aluminum coils, including rotary shear slitting, loop slitting, and simultaneous multi-blanking. These methods involve different techniques and equipment to precisely cut and separate aluminum coils into narrower strips or sheets. Each method has its advantages and is chosen based on factors like coil thickness, width, and desired output.

- Q:Are there any limitations to the maximum coil length of aluminum coils?

- Yes, there are limitations to the maximum coil length of aluminum coils. The length of aluminum coils is typically restricted by factors such as the capabilities of manufacturing equipment, transportation constraints, and handling limitations. Additionally, longer coils are more prone to issues like coil sagging and deformation during storage or handling. Therefore, there is a practical limit to the maximum coil length that can be produced and effectively utilized in various industries.

- Q:What are the different coil winding methods for aluminum coils?

- There are several different coil winding methods for aluminum coils, each with its own advantages and suitability for specific applications. 1. Layer winding: This method involves winding the aluminum wire in a single layer around the coil mandrel. It is commonly used in low voltage applications and provides good thermal conductivity and heat dissipation. 2. Random winding: In this method, the aluminum wire is wound randomly around the coil mandrel, without any specific pattern. It is often used in high voltage applications, as it helps to reduce the risk of corona discharge and provides better insulation. 3. Concentric winding: As the name suggests, concentric winding involves winding the aluminum wire in concentric circles around the coil mandrel. This method is suitable for applications where space is limited, as it allows for a higher number of turns in a compact coil. 4. Interleaved winding: Interleaved winding involves winding multiple layers of aluminum wire in an interleaved pattern. This method helps to reduce the overall size of the coil while maintaining a high number of turns and increasing the inductance. 5. Helical winding: In helical winding, the aluminum wire is wound in a helix pattern, either at a constant pitch or with varying pitch. This method is often used in applications where a high inductance is required, such as inductors and transformers. 6. Sectional winding: Sectional winding involves dividing the coil into multiple sections and winding each section separately. This method is commonly used in large-scale applications, as it allows for easier handling and installation of the coil. Each of these coil winding methods has its own strengths and considerations, and the choice of method depends on factors such as the specific application requirements, space limitations, and desired electrical characteristics.

- Q:How are aluminum coils tested for thickness and flatness?

- Aluminum coils are typically tested for thickness and flatness using specialized equipment such as a thickness gauge and a flatness tester. The thickness gauge measures the thickness of the coil at various points to ensure it meets the required specifications. Meanwhile, the flatness tester uses laser technology or a similar method to measure the surface flatness of the coil, identifying any deviations or irregularities. These tests are crucial to ensure the quality and consistency of the aluminum coils before they are further processed or used in various applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EN AW - 2219 Aluminium Sheet With Transparent PE Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords