Embossed Polycarbonate Solid PC Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: Sun Sheets & PC Embossed Sheets

Place of Origin: Zhejiang, China (Mainland)

Model Number: PE02

material: Polycarbonate

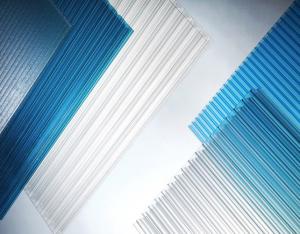

color: clear, green, blue , light blue , brown , opal , red , yellow

certification: ISO9001:2008, ROHS , SGS

Packaging & Delivery

Packaging Details: PE film protection on both side, fumigation pallet package for all solid sheet

Delivery Detail: 7-25days after confirm the prepayment

Specifications

1.10 years warranty

2.50 micro UV protection both side

3.thickness by customers

4.Great impact strength

5.Beautiful color

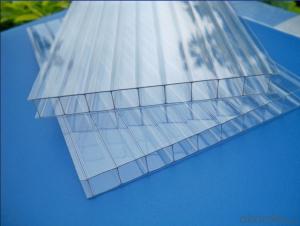

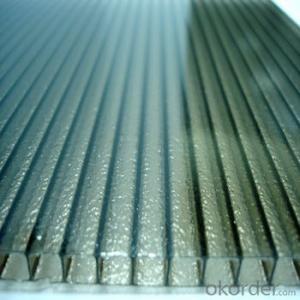

Embossed POLYCARBONATE PC SOLID SHEET

1. ISO9001:2008 proved

2. Size can be customized

3. Good impact resistance

PC embossed solid sheet is made by polycarbonate resin.

On the basis of common pc solid sheets technique and improvements of molds and production, the optical properties are changed as the surface structure of the product varies. Single side of pc embossed sheet contains UV protective layer, therefore, its mechanical properties, fire retardation, applicable temperature and chemical properties are consistent with common solid sheet. By changing the physical shape of the surface,

when light gets through the embossed sheet, it produces light scattering to get a vague hazy effect. Currently, pc embossed sheet is very ideal architecture material.

Features of Product

1. Light transmission Polycarbonate sheet has very good light transmission. Prolonged sun exposure of UV coated plate does not produce yellowing, fogging and poor light. The loss of light transmittance is 6% for embossed sheet and 15%-20% for PVC after ten years.

As light through its convex particles produces light scattering, it has good optical effect. For more information about light transmission, please feel free to contact us.

2. Anti-UV & Heat Insulation UV protective layer, 98% UV absorbed.

3. Light weight, high impact strength,excellent physical and mechanical properties and well bending performance The mechanical properties of pc embossed sheet are consistent with pc solid sheet. Maintaining good impact resistance for a long time in a wide temperature range (-40°C-120°C).

4. Fire retardation Embossed Polycarbonate sheet meets the national standard GB8624-1997 and ranks at B1 retardant material level. In the process of combustion, the sheet does not produce any smoke and toxic gases, and automatically turns off from the fire. It has good fire retardant properties.

5.Wide-ranging application, good weather-resistance Maintaining the stability of mechanical properties between -40°Cto +100°C, the sheet does not occur the cold crisp above -100°Cand without softening below 145°C. Small size change from 100°Cto -40°C, the rate of change is ≤ 0.3%. 2000 hours of artificial aging test towards the sheet, the yellowing degree was grade 2, and the transmission rate was decreased by 0.6%.

6. Soundproof The sheet can effectively reduce the noise, and is the best choice for soundproof.

7. Convenience for transportation and construction Light weight, standard size, convenient transportation & construction, easy cutting and punching,

cold bent and good processing performance.

8. Condensation inhibition Under normal circumstances, when the outdoor temperature is 0°C, room temperature is 23°Cand the indoor relative humidity is below 80%, the inner surface of the material does not frost.

9. Chemical resistance Polycarbonate Sheet can resist various kinds of harmful corrosive materials, such as organic acid, inorganic acid, vegetable oil, neutral salt solution, aliphatic hydrocarbon and alcohol, etc.

Storage, transportation and usage

Prohibit contact with wet cement surface and acid, alkaline material surfaces.

Prohibit contact with organic solvents and glue, paint composed thereof.

Keep the frame clean and the surface of rabbet groove flat.

Dust and dirt of the sheet are generally wiped by soft cloth or sponge with mild detergent first and then washed by water thoroughly.

Choose the right thickness, allow flexure radius.

If use self –drilling screws for fixing, the hole must be pre-drilled, and the aperture should be 1.5 times larger than the diameter of the screw.

Do not tighten the screw strongly, otherwise stress will arise, and crack on the sheet surface will appear.

Remain space for expanding, pay attention to inserting depth.

Expanding Value = linear expansion coefficient × length × the maximum temperature variation (linear expansion coefficient of pc sheet is 7×10-5mm/mm/°C).

Use neutral glass cement and right gasket. Never use gasket of PVC material. Use electrical tools (tungsten carbide saw) to cut, stabilize PC sheet to prevent their vibration.

Don't peel off protective film when cutting. In case that marks have to be made before cutting, try to mark on protective film.

If the marks must be made directly on PC sheets, use wax crayon instead of any sharp tool to mark.

Never peel off protective films until installation is completed. It is suggested that smooth side is installed towards sun in order to realize the effect of the UV protective layer.

Application

Commercial Building Lighting

Industrial architecture lighting

Stadium roof and indoor play area

Transportation infrastructure Residential architecture lighting

Exterior–protected construction and curtain wall

Bathroom and swimming pool

- Q:Lighting board and sunshine board which is good?

- This can not say which is better, can only say which product is suitable for you to use, the general enterprise plant lighting with lighting panels, and some flower room on the temperature requirements of the more stringent must use sun panels and shade net supporting the use.

- Q:Can the sun board bend?

- Different types of sun panels have different degrees of curvature. For example: the general car roof, rain roof there are many shopping malls outside the elevator channel that circle. If you are talking about it, it is not possible.

- Q:PC board greenhouses pc board generally use thick? What is the price? What about the current market price? Is the sun board a PC board?

- PC board greenhouse greenhouse generally refers to the sun board greenhouse shed, because the greenhouse shed with more use of PC sun panels, compared with the general 8-10MM, the cost of solid PC stamina cheaper than the price is calculated in accordance with ㎡, now The price of the market is about 40 square meters.

- Q:Who can tell me, plastic hollow board and PC sun board in the end what is the difference?

- Compared with the traditional ordinary film, it has the following advantages: ?1. Transparency reached 81%, has to keep up with ordinary film, can be planted on the promotion of vegetables. 2. Double-layer hollow structure, greatly weakened the strong exchange of hot and cold air, the greenhouse was basically in the state without dripping, greenhouse less mist, indoor relative humidity at a long time below 80%, greatly reducing the disease of the planted. 3. Double-layer hollow structure, good temperature effect, the thermal energy storage capacity of solar energy is strong, slow greenhouse temperature at night, are high-temperature covering materials. There are documented proofs that are 2 ° C higher than the temperature of the traditional shed. 4. Double hollow structure, the middle of the ribs, wind, snow pressure ability, not easy to tear. 5. Long life, do not have to replace each year, save hours, flowers, aquatic products, livestock and other greenhouse, has been used for more than 10 years of records. 6, due to the many advantages of the above, and after more than ten years of natural weather resistance test, so we believe that double insulation film (PE sun board) can be China's agriculture, animal husbandry (pig, chicken, raise Ducks, cattle, sheep, special breeding, etc.) aquaculture, flower planting, forestry nursery, etc., the construction of many low-cost, low humidity, long life, high-quality high-quality solar greenhouse.

- Q:What are the differences between plastic endurance boards and sun panels?

- Category: PC board is generally single and double board, in addition to multi-layer board, wave plate, film.

- Q:Which friends know how to remove the plastic film on the sun?

- Generally can be removed by hand But should pay attention not directly under the sun exposure, or may lead to thin film too thin, not easy to tear. After the installation of sun panels, should immediately tear off the film

- Q:What is the difference between the PC and the PC board?

- Two products are the same material, but the production process is not the same, the price is generally the same circumstances

- Q:Pc sun panels and frp lighting board what are the two differences

- 1. Material is a PC, one is FRP commonly known as glass fiber high performance UV resin; 2.PC is not resistant to corrosion, FRP is a good anti-corrosion performance; 3.PC sun board is hollow board, light transmission is better, FRP is usually a solid plate, usually semi-translucent state; 4. High-quality PC sunshine board surface has UV coating, anti-ultraviolet, anti-yellowing, such as Cortron sunshine board, and high-quality FRP surface is covered with thin film, such as red wave FRP lighting tile. 5.PC warranty period up to 10 years or so, FRP warranty up to 25 years;

- Q:Sunshine board can be used in what areas

- Sunshine board is widely used in industrial buildings, public buildings, civil buildings, modern commercial buildings safe lighting materials; also highways, elevated road noise screen, road signs advertising, light boxes advertising and display exhibition of excellent material; can also be used for subway , Underground garage export canopy; modern agriculture, aquaculture, indoor swimming pool lighting; bank transparent partition, jewelry display cabinet, police riot shield, police helmets and other riot material.

- Q:PC sunshine board, what material, what kind of good

- Hello, the thickness of the sun board is generally 10mm, 8mm, 6mm and other specifications, in the color also has a lake blue, transparent, white and other colors, available to users according to their actual needs and preferences to choose.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Embossed Polycarbonate Solid PC Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords