Embossed Panel Used for Anti-slipped Step Made in China Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

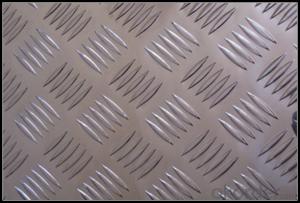

1.Structure of Embossed Panel Used for Anti-slipped Step Made in China Supplier

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Embossed Panel Used for Anti-slipped Step Made in China Supplier

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Embossed Panel Used for Anti-slipped Step Made in China Supplier Images

4.Specification of Embossed Panel Used for Anti-slipped Step Made in China Supplier

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:Are aluminum sheets suitable for marine applications?

- Yes, aluminum sheets are suitable for marine applications. Aluminum is lightweight, corrosion-resistant, and has excellent strength-to-weight ratio, making it ideal for various marine applications such as boat hulls, decks, and structural components. Additionally, aluminum's low maintenance requirements and durability in harsh marine environments further contribute to its suitability for such applications.

- Q:Are 101 aluminum sheets magnetic?

- No, 101 aluminum sheets are not magnetic as aluminum is a non-magnetic metal.

- Q:What are the different thicknesses available for aluminum sheet?

- The different thicknesses available for aluminum sheet vary depending on the specific requirements and applications. Common thicknesses for aluminum sheet range from 0.016 inches (0.41 mm) to 0.25 inches (6.35 mm), with numerous options in between. The appropriate thickness is determined by factors such as the intended use, structural requirements, and aesthetic preferences.

- Q:Are aluminum sheets suitable for pharmaceutical applications?

- Aluminum sheets are well-suited for pharmaceutical use, as they possess a range of advantageous properties. Firstly, their lightweight nature and exceptional resistance to corrosion make them an ideal choice for packaging pharmaceutical products. By shielding the contents from external factors like moisture, light, and oxygen, which could potentially compromise the medication's quality, aluminum sheets offer excellent protection. Additionally, aluminum sheets are highly malleable and can easily be molded into different shapes and sizes, allowing for customized packaging designs. Moreover, their availability in various thicknesses provides options for different types of pharmaceutical products, including tablets, capsules, and liquid medications. Furthermore, aluminum sheets boast a remarkable barrier property that effectively prevents the transfer of odors, flavors, and contaminants. This barrier ensures the integrity and safety of the medication throughout its entire shelf life. Furthermore, aluminum is a non-toxic material, guaranteeing that it does not react with drugs or alter their composition. This quality makes it an optimal choice for pharmaceutical applications, where maintaining the purity and stability of the medication is of utmost importance. In conclusion, aluminum sheets are highly suitable for pharmaceutical applications, thanks to their lightweight nature, corrosion resistance, barrier properties, and non-toxic composition. By efficiently safeguarding and preserving pharmaceutical products, they ensure the quality and safety of these crucial medications.

- Q:What are the different grades of aluminum sheets?

- The different grades of aluminum sheets include 1100, 3003, 5052, 6061, and 7075.

- Q:And isn't aluminum extremely bad for ones health?

- Antiperspirant does two things. It kills sanitizes the area so it kills resident bacteria that eat the oils and secretions in the skin and produce odor. The aluminum compounds plug the pores and prevent sweat secretion. But be careful, aluminum has been implicated in Alzheimers disease.

- Q:Can aluminum sheets be used for cladding?

- Yes, aluminum sheets can definitely be used for cladding. Aluminum is a popular choice for cladding due to its many beneficial properties. It is lightweight, durable, corrosion-resistant, and has excellent thermal and acoustic insulation properties. It is also highly malleable, allowing for various design possibilities. Aluminum cladding is commonly used in both residential and commercial buildings to provide protection, enhance aesthetics, and improve energy efficiency.

- Q:Are aluminum sheets suitable for automotive body reinforcements?

- Aluminum sheets, indeed, prove to be a fitting option for reinforcing automotive bodies. With its lightweight properties and exceptional strength-to-weight ratio, aluminum emerges as the perfect candidate for various automotive applications. Furthermore, its resistance to corrosion becomes vital for vehicles navigating through diverse weather conditions and encountering road salts. Moreover, the malleability and weldability of aluminum sheets make them easily adaptable and seamlessly integrated into the body structure. By incorporating aluminum sheets in automotive body reinforcements, the overall weight of the vehicle diminishes, leading to enhanced fuel efficiency and performance. Additionally, the recyclable nature of aluminum aligns perfectly with the automotive industry's growing emphasis on sustainability. Therefore, unquestionably, aluminum sheets represent an ideal choice for reinforcing automotive bodies.

- Q:Our production needs a large number of plating aluminum plate, consult domestic and imported aluminum plate difference?

- Guangdong Huayuan prosperous is the largest aluminum plate supplier 021-56808701, in Shanghai / Tianjin / Chongqing have logistics and storage, domestic aluminum plating surface coating treatment is less than imports, stamping coating is easy to fall,

- Q:Can aluminum sheets be used for fencing?

- Yes, aluminum sheets can be used for fencing. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion. It is commonly used in fencing applications due to its ability to withstand harsh weather conditions, including rain, snow, and UV rays. Aluminum sheets can be easily fabricated into different fence styles and designs, such as picket fences, privacy fences, or decorative fences. Additionally, aluminum fencing requires minimal maintenance as it does not rust or rot like other materials such as wood or iron. Overall, aluminum sheets provide an excellent option for fencing due to their strength, longevity, and aesthetic appeal.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Embossed Panel Used for Anti-slipped Step Made in China Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords