Embossed and Transparant Coated Aluminum Foils Used for Insulated Panels

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Embossed and Transparant Coated Aluminum Foils Used for Insulated Panels

We specialize in epoxy coated aluminum foils used for insulated ducts. Our coating include blue color, transparent color, gold color, silver color, etc.

Normally we use 1100 H22 as base coils and coated with clear epoxy, which is easily to be stuck with polyurathane and phenolic foam. Usual width include 1210mm, 1215mm, 1270mm, etc.

We have very strict inspection management including inspection for materials, inspection during production and inspection for finished goods.

Our test equipments include optical thickness gauge, cupping test machine, mettle Toledo, tensile-strength tester, busting strength tester, elongation tester, etc.

2.Main Features of Embossed and Transparant Coated Aluminum Foils Used for Insulated Panels

Moisture resistant

Light and easy for installation

Heat preservation

Low thermal conductivity

Durable and corrosion resistance

High heat reflection

Energy Saving

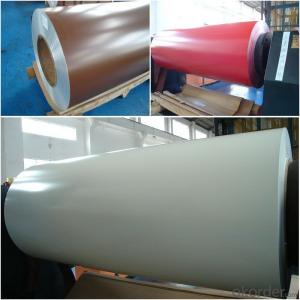

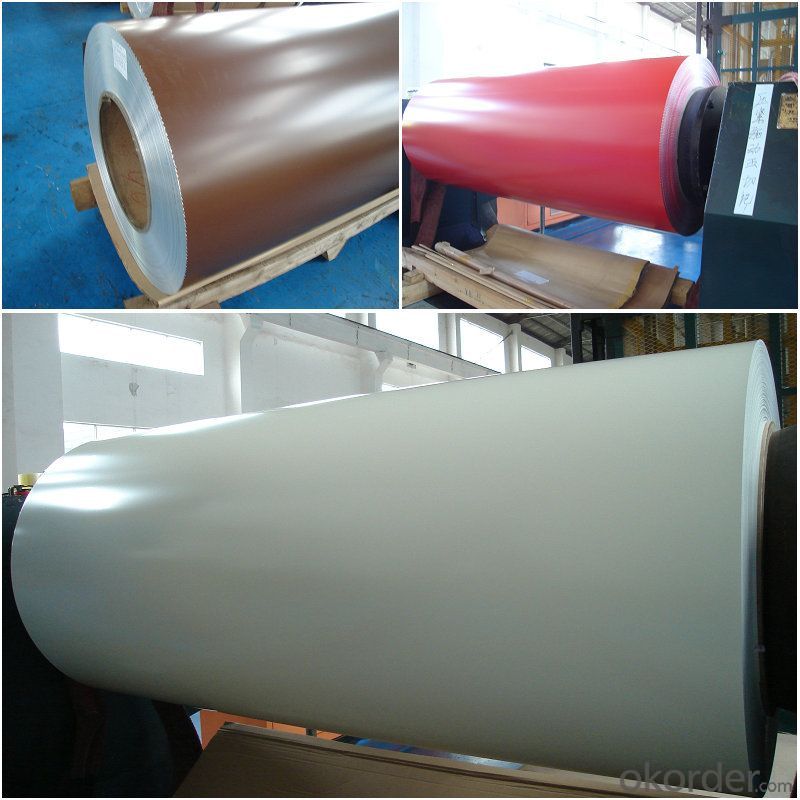

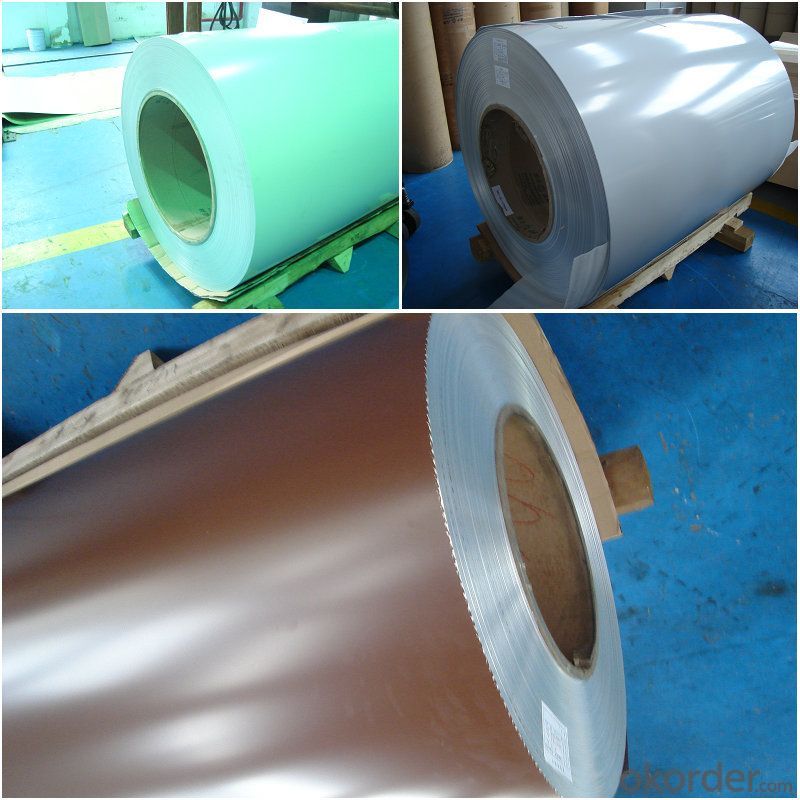

3. Embossed and Transparant Coated Aluminum Foils Used for Insulated Panels Images

4.Specification of Embossed and Transparant Coated Aluminum Foils Used for Insulated Panels

Alloy: 8011/ 1100/ 1235

Temper: O/H18/H22/H24/H26

Thickness & tolerance: 0.007-0.2mm (+/-6%)

Width & tolerance: 200mm-1650mm (+/-1mm)

Mechanical properties: Tensile strength (U.T.S) ≥ 80 MPA, Elongation ≥ 1%

Standard: GB/T3198/ASTM-B209/EN546

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:We went out for Chili's ribs the other nightI forgot how good ribs are, it isn't something we eat very oftenand I normally avoid Chili'sI was thinking it would be great to make some dry rub ribsMy favorite is a brown sugar rubWe have a nice gas grill, and an electric ovenHow would we go about cooking ribs on our own?

- try fabric softener and air dry the blanket

- Q:aa jet lifting off a runwayba bullet being fired from a guncdropping an aluminum can into the recycling binda space shuttle orbiting EarthI think it's c?If you know what the answer is, can you explain please?

- aa jet lifting off a runway - This is NOT projectile motion because other, just as lift and resistance of the air etc, than constant downward force due to earth are applying on the jeteffect of surrounding air cannot be neglected ba bullet being fired from a gun- This IS the example of Projectile motion neglecting the air resistance cdropping an aluminum can into the recycling bin - This CAN also be considered as projectile motion if we neglect air resistance as it is a special case of speed of projectile being zero and angle of projection 90 degrees below horizontalda space shuttle orbiting Earth - This is NOT the example of Projectile motion because although the magnitude of earth's force on satellite can be considered to be constant, its direction is all the time changing as the satellite travels round the earthSo b and c are the most correct answers.

- Q:Do people beleive Government is a slave to the people when they process you into FEMA camps during peacetime?

- A Skylit Drive, Blessthefall, I see stars, Attack Attack!, A City Serene, As The World Fades, Atreyu, A Bullet For Pretty Boy, Dead Means Nothing, A Day To Remember, Divide the Sky, From First To Last, Her Words Kill, I Hate Sally, I Am Alpha and Omega, A Long Winter, On The Sidewalk Bleeding, Reclaim The Fallen, Roses Are Red, Shadows Chasing Ghosts, Silence of a Silhouette, A Stained Glass Romance, A Thorn For Every HeartThis is all I can believe of on the second.

- Q:There are a couple of things I make and I'm getting tired of the same old stuffAny good ideas? I normally make potatoes and pork chops or I like to make chicken then shred it with some BBQ sauceI'm having cooker's block right now! Any and all recipe's will be appreciated!

- Beef Stroganoff 2 lbsbeef stew meat or round steak, cut into 1 cubes 3 tablespoons oil 2 tablespoons flour 1 large onion, chopped 1 teaspoon garlic 1 cup beef broth 1/4 lbfresh mushrooms, sliced 2 tablespoons tomato paste 1 tablespoon Worcestershire sauce 1 cup sour cream Salt and pepper to taste 1 package egg noodles, cooked Directions: In cooker, brown meatAdd flour and mix wellStir in onion, garlic powder, mushrooms, tomato paste, and Worcestershire sauceBlend thoroughlyClose the lid and bring to high pressureCook 20 minutesRelease the pressure and remove the lidStir in sour cream and blend wellServe over hot egg noodles And for desert: Spiced Apple Crunch- Serve this warm with whipped cream or a la modeInstead of apples you might try peaches1 cup dry bread crumbs 1/4 cup sugar 1/2 teaspoon cinnamon 1 lemon (juice and rind) 3 apples, sliced 1/4 cup butter, melted 2 cups water Directions: Butter a Fagor baking dish or 6 baking dishCombine bread crumbs, sugar, cinnamon, juice and rind of lemonPlace alternate layers of apples and crumbs in baking dishPour melted butter over ingredients and cover bowl firmly with aluminum foilPlace water, cooking rack and bowl in cookerClose lid and bring to high pressure and cook for 15 minutesRelease pressure, remove the lid and the steamer basket with dish or baking trayLoosen the foil and coolIf you wish to add more color and crunch, run the dish quickly under the broiler (watch carefully to prevent burning).

- Q:Consider the formation of one formula unit of AlF3 from neutral atomsIn the process, each aluminum atom electron(s) and each fluorine atom _ electron(s).(a) gains three; loses one(b) loses three; gains one(c) loses three; gains three(d) loses one; gains three(e)gains one; loses three

- (b) loses three , gains oneExplanation: Fluorine as most electronegative element takes electron in formation of compounds with other elementsAs halogen it can takes only one electron to reach stable electron configurationAll fluorine atoms in AlF?-molecule are bonded to the aluminum atomTherefore Aluminum atom loses 3 electrons.

- Q:%aluminum - %earth

- Abundance of aluminum in the crust is estimated to be about 8.2% of crustal mass, however this cannot be measured directly (it is estimated from the abundance of metal in the oceans). As the crust represents about 3% of the mass of the earth, and there are no more than trace amounts of aluminum elsewhere in the earth (ie mantle and core), aluminum represents about 8% * 3% = 0.25% of the total mass of the earth. Thus, the ratio of Aluminum to Earth (by mass) is about 1:40000

- Q:We don't have recycle pickup where we live, but we recycle aluminum and paper.

- If you are not going to take medication (which should only be taken when diet and exercise does not work; unlike the commercials tell you it is more rare than people think) then you will need to make some lifestyle changes for at least 90 days before you can really assess it's effectivnessA general healthy diet would be to eat 4 to 6 small meals a day (1 small meal every 3 to 4 hours) that includes fresh fruit, steamed vegetables, lean meats, whole grains and purified waterAvoid shell fish, red meats, fried foods and overly processed foods out of their natural stateBake, Broil, BBQ, Steam, Wok your foodsInclude an essential fatty acid oil like organic flax, hemp or fish oil that has been molecularly distilled (to avoid mercury contanimation)Don't be fooled by the cheap products that say they reduce cholesterol, no supplement can do better than a healthy diet, especially when their products are not a quality food sourceModerate daily alcohol consumption (1-2 beverages a day) will also help raise your good (HDL) cholesterolA regular exercise program with moderate intensity approx 3 times a week will do wonders for your health, beyond just your blood qualityTry to get between 3 to 4, 20 to 40 minutes of cardio a week (anything you like that is easy on the joints) and add a resistance program 1 - 2 times a week using compound movements for all big muscle groups (dumbbells, barbells or bodyweight movements)If you really stay focused and do this program consistantly for at least 90 days you should be able to make significant changes in your healthMake sure that you do check your blood after this program to rule out any health issues and if you haven't been training before you may want to get a physician's clearance first, but it is your choice ultimately.

- Q:I have a project where I need to measure the total lenght of an uneven surfaceI have looked for various instuments online that can do the job, but have not found one that is accurate enoughI need a digital readout in metric that can show the difference to the 100th decimal in mmIf there is no instument out there and ideas on the most accurate way to do this?

- do you mean m-16, i believe its 30 rounds

- Q:got one the other day prolly gonna make it for christmas eve dinner for me and my family (4 people).

- As any one who has been looking to placed on weight because thirteen (now 24 and eventually getting someplace with it), I can probably present an option standpointFirstly, losing two/three stones in eight weeks is badSensible weight reduction is not more than two lb per weekSecondly I have in no way identified someone to check out acai berry, however most often the extra hype there may be approximately anything, the extra you stand to be dissatisfiedThirdly, rely energyIt's unhappy, however see what you're consumingAssuming you're preserving the equal weight, that is the quantity you must hold that weightThen drop 500 an afternoonYou must see weight reduction really quickly, although now not always instantlyEventually this may increasingly tail off, and you'll be able to be preserving that new weight, so drop yet another 500 an afternoonIt's now not all approximately calorie counting although, it is approximately while you devourThe unmarried greatest cause why I wasn't placing on weight used to be that I ate at 3 instances an afternoon, and hardly ever external of thatSo I'd endorse that 3 foods an afternoon is what you desire and to avert snacking in among, irrespective of how healthful the snacks areIf you rather have to, high-quality devour a few water-founded vegetable like celeryAnd eventually, recreation is a well strategy to shed weightNote that you just cannot goal wherein you shed weight from (most effective wherein you construct muscle)Cut out useless trips on autos, buses, and many otherswherein you'll stroll and get out and perform a little going for walks or a few physical activitiesA fashionable alternative for women is Boxercise, combining boxing with a exercise, and I pay attention it is extremely slimming.

- Q:Whether abandoned aluminum foil has recovery value?

- Preparation of the main raw material utilization bauxite, aluminum hydroxide, zeolite spent catalyst, there are a wet preparation method, electrolysis method or the like. Some scholars believe that the economic value of waste aluminum foil having a high recycling. He used the scope of waste aluminum foil prepared PAC optimal conditions and water purification through experiments.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Embossed and Transparant Coated Aluminum Foils Used for Insulated Panels

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords