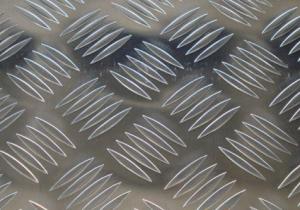

Embossed Aluminum Sheet 1xxx3xxx5xxx Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Aluminum Foil

Often referred to as tin foil, is aluminium prepared in thin metal leaves with a thickness less than 0.2 mm (7.9 mils); thinner gauges down to 6 micrometres (0.24 mils) are also commonly used. In the United States, foils are commonly gauged in thousandths of an inch or mils. Standard household foil is typically 0.016 mm (0.63 mils) thick, and heavy duty household foil is typically 0.024 mm (0.94 mils). The foil is pliable, and can be readily bent or wrapped around objects. Thin foils are fragile and are sometimes laminated to other materials such asplastics or paper to make them more useful. Aluminium foil supplanted tin foil in the mid 20th century.

2.Main Features of the Aluminum Foil

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

6.Our quality is based on EN,ASTM,JIS.

7.We provide free sample service.

8.The products can be made according to your requirement.

9.Sincerely welcome your inquiry.

3. Aluminium Foil Images:

4. Aluminium Foil Specification:

Product application range:

Suitable for: Tobacco, food, beer, beverage, decoration, electric cable, electrolytic capacitor, medicine and air-conditioner.

Alloy: 1070\1060\1050\110\1200\1145\1235\3003\3102\8011\8011A\8079\8006

Temper:0/H14\H16\H18\H26\H24\H22

Thickness: 0.006mm_0.2mm

Width: 75 mm-1410 mm

Coil inner diameter: 75.00\ 76.20\ 150.00\ 200.00mm

Aluminum foil coil outer diameter:100 mm-1000 mm

Industry | Type | Typical thickness (mm) | Processing method | Usage |

Packing | Food | 0.006-0.009 | Compound paper, plastics, thin film, embossing & colorizing, printing | Candy, milk and milk product, powder food, drink, tea, bread and all kinds of snack food |

Tobacco | 0.006-0.007 | Compound paper, colorizing, printing | Internal and external packing for cigarette | |

Medicine | 0.006-0.02 | Compounding, coating, printing | Tablet, granular formulation | |

Cosmetics | 0.006-0.009 | Compound printing | ||

Bottle caps | 0.011-0.2 | Printing, scouring printing | Bottle caps, the beer bottle, the fruit juice bottle seal, all kinds of trademarks, etc. | |

Daily use | Household | 0.01-0.2 | Small coiling | Packing for family food etc. |

Utensils | 0...011-0.1 | Molding processing | Food utensils, coal gas hood, ashtray and all kinds of utensils | |

Electrical equipment industry | electrolytic capacitor | 0.015-0.11 | Eroding in the special medium | electrolytic capacitor |

Electrolytic capacitor | 0.006-0.016 | Liner oil paper | capacitor | |

Radiator | 0.09-0.2 | Punching Fin | All kinds of air conditioning radiators | |

Electric cable | 0.15-0.2 | aluminium plastics compound | Electric cable wrap | |

Construction industry | Heat-insulating material | 0.006-0.03 | compound materials | Heat-insulating material for house, pipeline etc. |

Decorating board | 0.03-0.2 | Paints coated compound materials | Decorating board for construction use | |

Aluminium plastic pipeline | 0.2 | Compound polyethylene plastic | All kinds of pipelines | |

Special specification | Air conditioning foil | 0.105-0.115 | 8011 H22 O | |

Wine banner foil | 0.0105-0.0115 | 8011 O | ||

Foil for medicine | 0.02-0.025 | 8011 H18 |

5. FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:I know aluminium forms a protective layer of aluminum oxide and hence water does not corrodes it easily.However, since the oxide is amphoteric, won't it react with acids and subsequently be dissolved?What is the main reason aluminium cans are used?

- Because of the aluminum chemical properties. Aluminum Oxide (Al2O3) is an extremely hard and compact material, so when the metal is exposed, it gets a very thin coat of Al2O3 that has a 9 hardness (only diamond is harder), that protects the rest of the metal from the atmosphere. Also, you should question if the phosphoric acid actually attacks aluminum, that is because that acid is found in Pepsi and coke..., BUT, as far as i know cans have a little plastic coat inside..., so the liquid does not get in touch with the aluminum.

- Q:What are the different packaging options available for aluminum sheets during transportation?

- There are several packaging options available for aluminum sheets during transportation. Some common methods include wrapping the sheets in protective film or paper, using wooden crates or pallets to stack and secure the sheets, and using cardboard or plastic edge protectors to prevent damage. Additionally, aluminum sheets can also be packaged in custom-cut foam or bubble wrap for added cushioning and protection during transit.

- Q:I use an aluminum chloride deodorant at night for hyperidrosis...I'm scared I may get senile dementia when i get older!!!!! can anyone give advice??? pls..i've been using it for 3yrs

- Aluminium has been established as a neurotoxin.[1] Aluminium chloride, an aluminum salt that is commonly used in antiperspirants, is also commonly used in studies on aluminium-induced neurotoxicity[2][3][4][5][6]. Aluminium itself adversely affects the blood-brain barrier, is capable of causing DNA damage, and has adverse epigenetic effects.[7][8] Research has shown that the aluminium salts used in antiperspirants have detrimental effects to a number of species such as non-human primates[9], mice[10], dogs[11] and others. An increased amount of Aluminium is also present in the brains of many Alzheimer's patients, although it is not yet known if this link is causal.[12][13] I found this for you I hope it helps. Alzhaimer is also genetic. As it says here there is a link. Among that there could be other links to this disease. The best way is to keep your mind active. Active meaning reading even as you get older. I have witness patients come in to a home facility alert and then they give up. They stop reading, interacting and using their mind. Do further research and talk to your doctor.

- Q:Can aluminum sheets be used for cryogenic applications?

- Yes, aluminum sheets can be used for cryogenic applications. Aluminum has excellent thermal conductivity and can withstand low temperatures, making it suitable for cryogenic environments. Additionally, aluminum's lightweight and corrosion-resistant properties make it a popular choice in various cryogenic applications such as aerospace, scientific research, and cryogenic storage systems.

- Q:Can 101 aluminum sheets be used in architectural cladding?

- Certainly, architectural cladding can indeed utilize 101 aluminum sheets. The lightweight nature, durability, and resistance to corrosion make aluminum a favored option for architectural cladding. Specifically, grade 101 aluminum sheets find widespread use in architectural applications due to their impressive formability and easy workability. These sheets can be effortlessly cut, shaped, and joined to fashion tailor-made cladding solutions. Moreover, aluminum offers the possibility of being coated or anodized, allowing for enhanced aesthetics and added weather protection. Consequently, it is evident that 101 aluminum sheets prove suitable for various architectural cladding projects.

- Q:What are the surface treatment requirements for aluminum sheets in the food industry?

- In the food industry, aluminum sheets used for food packaging and handling must undergo specific surface treatments to meet hygiene and safety standards. The surface treatment requirements for aluminum sheets in the food industry typically involve processes like cleaning, degreasing, and anodizing. These treatments remove any dirt, oils, or contaminants, and create a protective layer on the aluminum surface to prevent corrosion and ensure the sheets are safe for food contact. Additionally, the surface treatments may also include specific coatings or laminations to enhance the barrier properties and maintain the quality and freshness of the food products.

- Q:Can 101 aluminum sheets be anodized for medical equipment applications?

- Yes, 101 aluminum sheets can be anodized for medical equipment applications. Anodizing is a process that creates a protective layer on the surface of aluminum, enhancing its corrosion resistance, durability, and aesthetic appearance. It is commonly used in the medical industry to improve the performance and longevity of equipment, as well as to maintain cleanliness and sterility. The specific alloy of aluminum used, such as 101, does not typically impact the anodizing process, as anodizing can be applied to various grades of aluminum. However, it is important to consult with an anodizing specialist or manufacturer to ensure that the specific alloy is suitable for the intended medical equipment application and to determine the most suitable anodizing process and specifications.

- Q:What is the elongation percentage of 101 aluminum sheets?

- The elongation percentage of 101 aluminum sheets typically ranges between 12% and 30%, depending on the specific grade and thickness of the sheet.

- Q:As for graphite and aluminum sheet, which one has a better thermal conductivity?

- Aluminum sheet has a better thermal conductivity, because metal is good conductor of heat, graphite is n't metal.

- Q:im wondering what happens if you MIG weld aluminum with the correct wire but without using a shielding gas? Would it just be extremely messy or does there HAVE to be an inert gas flowing for it to bond?thanks

- welding reaches high enough heats that the oxygen and hydrogen, and nitrogen that naturally occure in our atmosphere will combine and or otherwise interfere with the re-solidification of the molten metal. This will completely destroy the new molecular structure and there will be no strength in the new metal. All welding uses some form of preventing the atmospheres oxygen,nitrogen, and hydrogen from effecting the alloy structure. Other elements can also be combined in the chemical reaction if your environment or your project are not clean. All metals oxidize on their surface. That means combine with oxygen. It is the process we call rust when refering to iron which in the case of iron never stops rusting until it rusts away. for the most part all other metals oxidize on their surface and stop. this is what gives their great protection and helps in deciding their use,as with aluminum. You can create environments that will cause thsese other metals to continue to oxidize as with electrolosis, but that is getting more complex. SOO with aluminum it is a good idea to brush the oxidation layer off the surfaces to be welded so this oxidised aluminun does not become a source of contamination in the new weld metal. It is recomended to use a clean stainless steel bristle brush as an iron brush can contaminate. Brushing can generally last for many hours even days but you can see the dull color re appear as it oxidizes over time. Another comon source of oxygen and hydrogen is water. That is what the purpose of low hydrogen electrodes is, though these are not used in aluminum. The military builds the aluminum hulls for the bradley and other vehicles in San Jose partly because the relative humidity is best for mig welding aluminum there. so you can see the concepts can become conflicting. Always use argon with aluminum. Argon can be mixed with small percentages of helium too.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Embossed Aluminum Sheet 1xxx3xxx5xxx Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords