Embossed Aluminum Foil for Pre Insulated Duct Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Embossed Aluminum Foil for Pre Insulated Duct Board

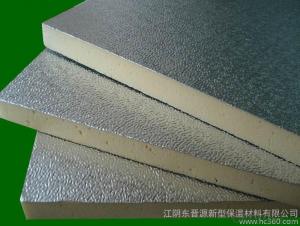

1.Structure of Embossed Aluminum Foil for Pre Insulated Duct Board

HVAC Aluminum Foil Duct Board is used for central air conditioning duct system. It is energy saving and environment-friendly. It had become more and more popular all over the world. This new generation duct is ideal for specifications where space or weight is restricted.

HVAC Aluminum Foil Duct Board can offers a high performance, light weight and robust ductwork system that requires only a single fix installation process. It is widely used in the ventilation systems of central air conditioning units in hospital, hotel, market, supermarket, guesthouse, airport, stadium, workshop, food store, pure project and so on.

HVAC Aluminum Foil Duct Board consist of 20mm thickness foam insulation faced on both sides with 80micron thickness aluminum foil, or inside with 80micron thickness aluminum foil & outside with 200 micron thickness aluminum sheet.

2.Main Features of Embossed Aluminum Foil for Pre Insulated Duct Board:

Air Duct Panel / Pre-insulated Duct Panel / HVAC Duct Panel :

HVAC Aluminum Foil Duct Board

1. Be used for HVAC Duct system;

2. BS 476 Part 6&7 Class 0.

3. Low thermal conductivity.

3.Embossed Aluminum Foil for Pre Insulated Duct Board Images

Our embossed aluminum sheet/Coil series include:

1.diamond embossed aluminum sheet/Coil

2.orange peel embossed aluminum sheet/Coil

3.stucco embossed aluminum sheet/Coil

4. Embossed Aluminum Foil for Pre Insulated Duct Board Specification

1.Name:Air Duct Tube Aluminum Foil

2.Alloy No.; 3003 8011

3.Temper: H16 H18 H22 H24 H26

4.Thickness: 0.09-0.10mm

5.Thickness Tolerance: +/-0.02mm

6.Width: 50-90mm

7.Width Tolerance: +/-1mm

8.Inner Diameter: 76/152mm(paper core)

9.Outer Diameter: 700-1000mm

10.Packing: wooden cases

11.Certificate: FORM A, CO ,FORM E ,FORM B ,MTC, SGS and ROHS(client paid for it), MTC

12. Surface Quality: without any dent, scratches, oiliness , oxidation .

13. Chemicial composite and Machinary Property: Meet with GB/T, JIS,ENAW, ASTM standard

13.Month Capacity: 5000MT/month

14,exporting port: Tianjin, Shanghai

15. payment: TT or LC at sight

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long for your delivery time?

Commonly 30 working days can be served. If you need the products urgently, we can shorten the delivery time into 20 days.

3.Do you support customer required size or dimension?

Yes, we can make as clients’ required.

- Q:Can foil be insulated?Indeed, the foil is reflective of the sun's rays

- Aluminum foil paper as an industrial raw and auxiliary materials, products are mainly used in packaging, protection, daily necessities, buildings and so on. Aluminum foil and aluminum foil aluminum foil backing paper by bonding paper. Soft, easy to change, such as paper, and does not rebound after deformation. The utility model can be characterized in that the utility model has the advantages of ensuring shading, no falling, no light transmission, no pollution, and low price, and is used for moisture-proof and decorative packaging of high-grade cigarettes, candies and the like.

- Q:Aluminum foil and aluminum foil is not the same?

- Aluminum foil and aluminum foil is the same.Also as a foil, aluminum foil, in Hongkong, also known as tin foil, is machined by aluminum foil mill into a sheet thickness below 0.2mm, mainly used for kitchen cooking, food containers, or used to make some simple cleaning materials. Thousands of tons of aluminium foil are used around the world for the protection and packing of food, cosmetics and chemicals.

- Q:Is aluminum foil harmful to human body?

- There is no harm in foil (Aluminium foil), also known as the Hongkong aluminum foil, aluminum foil, aluminum is a metal flat manufacturing tool, mainly used for kitchen cooking, food containers, or used to make some simple cleaning materials. Thousands of tons of aluminium foil are used around the world for the protection and packing of food, cosmetics and chemicals. Most of the foil is shiny on one side and the other dull. Aluminum foil for food can be wrapped on both sides, and it is generally recommended to enhance the heat transfer effect with bright bread wrap

- Q:What color is the aluminum foil in the air conditioner?

- Aluminum foil instant tin foil, aluminum foil is rapid heat transfer, uniform heat dissipation, the food will not be scorched, dirty oil tank, can prevent food cooked at the same time, wrapped in food can also reduce food loss with foil water loss.

- Q:What is aluminum foil?Direct rolling with metallic aluminium

- Characteristic:(1) the surface of aluminum foil is clean and sanitary, and no bacteria or microorganisms can grow on its surface.(2) aluminum foil is a non-toxic packaging material, it can be in direct contact with food, and there is no harm to human health.(3) aluminum foil is an odorless and odorless packing material, which will not cause any peculiar smell of packaged food.(4) if the foil itself is not volatile, the food itself and the packaged food will never dry or contract.(5) there is no grease penetration in aluminum foil, whether at high temperature or at low temperature.

- Q:Can aluminum foil be harmful to human body?

- functionAluminum foil is usually used for food delivery (e.g. aluminum foil trays) and for roasting, for example, bean sprouts, potatoes, sweet potatoes, etc., are used for roasting, so as not to scorch them. Sometimes used as a decoration. The modern aluminum foil is made of aluminum and also used as an aluminum electrode for electrolysis. There are also hair stylist for foil guests perm. Some people also use aluminum foil to absorb the oil in the soup. Aluminum foil paper is also widely used in insulation, heat exchange, and as a conductor. Usually used in paper packaging, beverage packaging, and aluminum foil in food packaging bags of only 6.5 microns. This thin layer of aluminum can maintain the flavor, waterproof, anti-bacterial and anti fouling

- Q:Aluminum foil surface, SBS roll multilayer superposition, waterproof effect is good?

- Generally speaking, SBS waterproofing membrane superimposed use, will certainly be better than the use of single layer. But the first time with the construction of aluminum thread with a little waste. Because aluminum Bu in coil plays only a reflective insulation function, so if the two house the first time it is not necessary to use the superposition with aluminum Bu, PE film can be second times, and then the aluminum coil Bu

- Q:Aluminum foil bag, VCI plastic bag, PE plastic bag, which package has good anti rust effect? It is used for the packing of iron and steel parts

- The advantage of aluminum foil is that the barrier is very good, the moisture permeability and oxygen permeability are very low, but the disadvantages are also obvious, the cost is high, opaque, not suitable for use in high humidity areas, or outer packing.

- Q:What are the characteristics of aluminium foil waterproof coiled material?

- Aluminum foil (Aluminium foil), also known as tin foil, aluminum foil, aluminum foil, aluminum foil and aluminum foil backing paper by bonding paper.

- Q:Can the potatoes be heated by foil?

- . Aluminum foil has a microwave isolation effect, that is, the microwave can not penetrate the aluminum foil, so the food will not be heated by microwave energy.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Embossed Aluminum Foil for Pre Insulated Duct Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords