Embossed Aluminum Colourful Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mirror five bars embossed aluminum sheet

Product Description

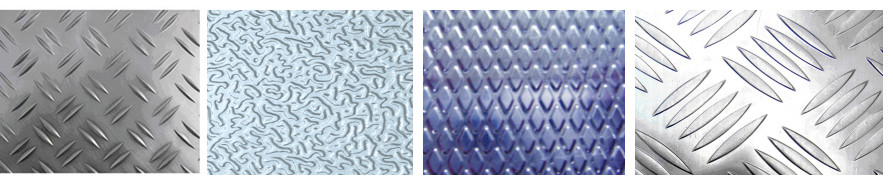

ITEM | ALLOY | PATTERN | THICKNESS | WIDTH | APPLICATION |

ALUMINIUM CHECKERED PLATE | 1000SERIES 3000SERIES 5000SERIES 6000SERIES | DIAMOND 2 BARS 3 BARS 5 BARS | 0.8MM-10MM | 900MM-1600MM | Lighting,construction,printing,packing,decorative, |

Technical Specifications

Thickness: 0.8-10mm

Width: 900-1600mm

Length: 800-8000mm

Material (alloy): 1100, 1050, 3003, 3103, 5052, 5754, 5083, 6061, 6082

Type embossed: diamond(one bar), three bars, five bars,etc

Application

the chequered aluminum sheet Mainly used in Construction , decoration,packaging, printing, cover material,piping, electronic elements, referigeration, air conditioner, automobile, etc

Company Information

CNBM is the key enterprise of aluminum manufacturing, researching and development in CNBM Group, which was founded in 1984.

The aluminum circle, mirror aluminum sheet, plain auminum foil, stucco embossed aluminum foil and aluminum strip are our main products, and our products have been passed the CCC certificate, SGS certificate, BV certificate etc which certificated by the third party, and also CNBM Aluminum has obtained by the ISO9001 certificate, our annual capacity ability is more than 1 billiion.

Packaging & Delivery

| Packaging Details: | 1. Seaworthy export wooden pallet 2. With damp proof film as first layer 3. Kraft paper as second layer 4. Cardboard card as third layer 5. Criss-cross steel strip to fix outside. |

| Delivery Detail: | 10-15 days after receiving the deposit chequered aluminum sheet |

- Q:What is the lifespan of an aluminum sheet?

- Factors such as the grade of aluminum, sheet thickness, environmental exposure, and maintenance level can all influence the lifespan of an aluminum sheet. Aluminum sheets are generally recognized for their durability and extended longevity. Aluminum possesses corrosion resistance, enabling it to endure moisture and environmental elements without deteriorating rapidly, unlike other materials. This quality makes aluminum sheets highly resistant to rust and corrosion, thereby significantly increasing their lifespan. Typically, aluminum sheets can endure for 20 to 50 years, and sometimes even longer. However, it is important to consider that this estimate may vary depending on the specific application and conditions to which the sheet is subjected. For instance, aluminum sheets utilized in outdoor applications like roofing or siding may have a shorter lifespan due to exposure to harsh weather conditions such as UV radiation, extreme temperatures, and heavy rainfall. To maximize the lifespan of an aluminum sheet, proper maintenance and care are vital. This entails regular cleaning to eliminate any accumulated dirt or debris that may potentially cause damage. Additionally, applying protective coatings or treatments can further enhance the sheet's resistance to corrosion, thus extending its lifespan. Overall, when adequately maintained and used in suitable applications, aluminum sheets can boast a lengthy lifespan. This makes them a dependable and cost-effective choice for diverse industries and purposes.

- Q:Which kind of material does aluminum sheet(aluminum oxide) belong to?

- it's metal and belongs to hardware

- Q:Can aluminum sheets be used for heat sinks?

- Indeed, heat sinks can utilize aluminum sheets. Due to its outstanding thermal conductivity, aluminum serves as an ideal substance for efficiently diverting heat away from electronic parts. With the ability to be fashioned into different dimensions and configurations, aluminum sheets can optimize the dispersion of heat. They find widespread employment in computer processors, LED lights, and power electronics, where the preservation of peak performance and the prevention of overheating hinge on effective heat dissipation. Moreover, the lightweight nature and cost-effectiveness of aluminum sheets render them highly favored for heat sink purposes.

- Q:I am doing some exam review and do not know how to do these...Calculate the number of Nitrate ions in 3.99 g or aluminum nitrate.

- OK - first you need the ENTIRE mass of the aluminum nitrate (gram formula mass). You need the correct formula for aluminum nitrate, then add up the atomic masses from the periodic chart. Then, you need to convert 3.99 g of aluminum nitrate to moles of aluminum nitrate. (grams/formula mass = moles) Then, you need to take into account how many moles of nitrate ions are in a mole (look at the correct formula for aluminum nitrate). Then multiply by the number of moles you calculated (moles of ions per molecule x #moles). This would be moles of ions. You need individual ions you would the multiply by 6.02 x 10^23 ions/mole. SO: grams of sample divided by formula mass x #nitrate ions per molecule x (6.023 x 10^23 ions per mole) = # ions

- Q:Can aluminum sheets be welded or soldered?

- Yes, aluminum sheets can be welded or soldered.

- Q:Can aluminum sheets be bent or formed?

- Yes, aluminum sheets can be bent or formed. Aluminum is a highly malleable and ductile metal, which means it can easily be shaped or bent without breaking. This characteristic makes it a popular choice for various applications, such as manufacturing automotive parts, aircraft structures, and household items. Aluminum sheets can be bent or formed using various techniques, such as press braking, roll bending, and stretch forming. These methods allow the aluminum sheets to be shaped into different angles or curves to meet specific design requirements.

- Q:I'm gonna drop the dime and get a bass boat. other than weight why is a fiberglass better than aluminum?I'm looking at the difference between the top of the line BassTracker and the bottom of the line Nitro. I only want about a 90 -115 hp and I'm gonna buy a couple years old to save some money.. so what are the pros - cons?

- Best Aluminum Bass Boat

- Q:Can aluminum sheets be easily formed or bent?

- Yes, aluminum sheets can be easily formed or bent. Aluminum is a highly malleable metal, which means it can be easily shaped into various forms without cracking or breaking. This property makes aluminum sheets a popular choice in industries such as automotive, aerospace, and construction, where complex shapes and designs are required. The malleability of aluminum allows for easy manipulation through techniques like rolling, pressing, or bending, enabling the creation of intricate and customized products. Additionally, aluminum's lightweight nature and high strength-to-weight ratio make it an ideal material for forming or bending applications, as it can be shaped without adding excessive weight to the final product.

- Q:What are the common surface finishes for aluminum sheets?

- Some common surface finishes for aluminum sheets include mill finish, brushed finish, anodized finish, and powder-coated finish. Mill finish refers to the untreated surface of the aluminum sheet, which has a slightly rough texture and may have visible imperfections. This is the most basic and economical option, commonly used for industrial applications or as a base for further finishing processes. Brushed finish involves a mechanical brushing process that creates a series of fine parallel lines on the surface of the aluminum sheet. This finish gives the metal a textured appearance and can help to hide small scratches or imperfections. Anodized finish is achieved through an electrochemical process called anodization, which creates a protective oxide layer on the surface of the aluminum. This finish enhances the corrosion resistance and durability of the metal while also allowing for a variety of color options. Anodized aluminum sheets are often used in architectural applications or for decorative purposes. Powder-coated finish involves applying a dry powder to the surface of the aluminum sheet and then baking it at high temperatures. This process creates a durable and attractive finish that is resistant to chipping, scratching, and fading. Powder-coated aluminum sheets are commonly used for outdoor applications, such as building facades, signage, or automotive parts. Overall, the choice of surface finish for aluminum sheets depends on the desired appearance, functionality, and specific requirements of the application.

- Q:what are the differences between aluminium , iron , steel.... properties like strength , durability , corrosion resistance properties...finally which is cost efficient and best for all purpose..??

- steel okorder /

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Embossed Aluminum Colourful Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords