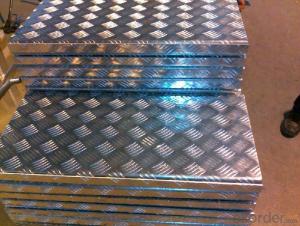

Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specifications of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

Alloy | AA1xxx(1050,1060,1070,1100 etc.) |

AA3xxx(3003,3004,3005,3105 etc.) | |

AA5xxx(5005,5052,5083,5754 etc.) | |

Temper | H14,H16,H18,H22,H24,H26,H32 |

Thickness | 0.2-20mm |

Width | 10mm-1500mm |

Embossed | Diamond, Stucco, Three/Five Bars |

Standard | GB/T3880-2012,EN485, ASTM B209 |

Application | Anti-Skid Floor, Decoration Floor etc |

Special specification or color is available as per customers’ requirement | |

2. Usage/Application of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

The embossed aluminum coil/sheet are widely used for decorative purpose in construction, packing and appliance. It is also very commonly used for anti-splippery purposes in vehicles and public places.

3. Packaging & Delivery of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

Seaworthy package, plastic bag covered inside, carton wrapped outside, paper core, on the wooden pallet. Pallet weight: 2000-25000KG.

4. Production Flow of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

Melting-Rolling- Cutting- Annealing--Packing

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines. Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC.

- Q:AND WAT R THE THECNOLOGICAL ANDCOSTS AND BENEFITESOF USING ALUMINUM? what health -related and environment-related issues gave surface as aresult of its widespread use in society?

- airplanes are made from aluminum. certain beverages are also. aluminum is cheaper and lighter. the biggest problem is the amount of electricity that it takes to make aluminum

- Q:Whether its strong or not, im looking to get grime like stains out of my aluminum rims. It looks like they can be worked out after time, but i dont think i want to risk acidic products because im not 100% sure if theres a clear coat (i have eagle 077s if that helps!). I have read weird ideas from buffing with baby oil to brake cleaner since its super strong but dont wanna tear up my nice new wheels! Any input is greatly appreciated

- The best polish I have found is BlingMaster Aluminator. Brought back my wheels to look like Brand New.

- Q:Are 101 aluminum sheets suitable for heat exchangers?

- No, 101 aluminum sheets are not suitable for heat exchangers. Heat exchangers require materials with good thermal conductivity and corrosion resistance. While aluminum is a good conductor of heat, 101 aluminum alloy does not possess the necessary corrosion resistance properties required for heat exchangers. Other aluminum alloys, such as 3003 or 5052, are commonly used for heat exchangers due to their excellent thermal conductivity and resistance to corrosion.

- Q:Can aluminum sheets be used for food processing equipment?

- Aluminum sheets are suitable for food processing equipment. The food industry favors aluminum for its many advantageous properties. It is lightweight, long-lasting, resistant to corrosion, and possesses excellent thermal conductivity. These attributes make aluminum sheets perfect for various applications in food processing equipment, including mixing bowls, cooking utensils, baking trays, and food storage containers. Furthermore, aluminum is non-toxic and does not interact with food, guaranteeing the safety and quality of processed products. Nevertheless, it is important to note that aluminum should not directly touch acidic or alkaline foods as it may react and impact the taste or quality of the food. In such instances, a protective barrier or lining should be employed. On the whole, aluminum sheets are extensively employed in the food industry due to their adaptability, durability, and food-safe characteristics.

- Q:Are aluminum sheets suitable for electrical bus bars?

- Certain applications may find aluminum sheets suitable for use in electrical bus bars. Aluminum possesses several properties that make it a viable choice for bus bars. Firstly, aluminum is a lightweight material, which can be advantageous in situations where weight reduction is crucial. Furthermore, aluminum exhibits good electrical conductivity, although it falls short of copper in terms of conductivity. Nevertheless, aluminum bus bars can still handle high electrical currents and are commonly employed in power distribution systems. However, one drawback of aluminum bus bars is their higher resistance compared to copper bus bars. Consequently, they have a tendency to generate more heat, particularly under heavy current loads. To address this issue, aluminum bus bars are often designed with larger cross-sectional areas to minimize resistance and dissipate heat more effectively. Another challenge associated with aluminum bus bars is their vulnerability to oxidation and corrosion. This concern can be tackled by applying protective coatings or utilizing alloys that offer superior corrosion resistance. Additionally, it is crucial to ensure proper insulation and avoid contact with dissimilar metals to prevent galvanic corrosion. In conclusion, aluminum sheets can serve as suitable materials for electrical bus bars, particularly in scenarios where weight reduction is a priority. However, careful consideration must be given to factors such as electrical conductivity, heat dissipation, and corrosion resistance to ensure optimal performance and longevity of the bus bars.

- Q:Can aluminum sheets be used for boat building?

- Boat building can indeed incorporate aluminum sheets. The lightweight quality, durability, and resistance to corrosion make aluminum a favored material for constructing boats. Small recreational boats, larger yachts, and even commercial vessels commonly employ aluminum sheets in their construction. These sheets offer numerous benefits, including ease of manipulation, a remarkable strength-to-weight ratio, and minimal upkeep requirements. Furthermore, aluminum boats are esteemed for their exceptional buoyancy, stability, and fuel efficiency. All in all, utilizing aluminum sheets is a suitable and dependable choice for boat building.

- Q:Can aluminum sheets be used in food packaging?

- Yes, aluminum sheets can be and are commonly used in food packaging. Aluminum is a popular choice for food packaging due to its excellent barrier properties, which protect the food from light, oxygen, moisture, and other external factors that can spoil or contaminate it. Aluminum sheets are lightweight, durable, and resistant to corrosion, making them suitable for various types of food packaging, such as foil wraps, containers, trays, and pouches. Additionally, aluminum is a recyclable material, making it an environmentally friendly choice for food packaging.

- Q:Solid aluminum or solid wooden boxes-no glass top. Would glass make the temperature rise more quickly? (ie Solar)? Thanks.Joseph

- Aluminum is a very good conductor of heat and wood is a very poor conductor of heat. If the heat source is inside the box with the food, it will heat quicker in a wooden box. If the heat source is outside the box it will heat quicker in an aluminum box. Having a glass top would be equivalent to having the heat inside the box so a wood box with a glass top will make a better solar heater.

- Q:Can aluminum sheets be used for heat exchanger fins?

- Absolutely, heat exchanger fins can indeed make use of aluminum sheets. Aluminum stands out as a favored option for heat exchanger fins owing to its remarkable thermal conductivity, lightweight attributes, and resistance to corrosion. The utilization of aluminum fins enables efficient heat transfer to take place between the fluid and its surroundings. Moreover, aluminum sheets can be effortlessly molded into diverse fin shapes and sizes, allowing for a great deal of design flexibility. All in all, aluminum sheets prove to be a fitting and frequently employed material for heat exchanger fins.

- Q:What is the typical modulus of elasticity for aluminum sheets?

- The typical modulus of elasticity for aluminum sheets is around 70 GPa (gigapascals) or 10 million psi (pounds per square inch). However, it is important to note that the modulus of elasticity can vary depending on the specific alloy and temper of the aluminum sheet.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords