Eleven mm Cold Rolled Steel Rebars with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Eleven mm Cold Rolled Steel Rebars with High Quality:

Name | Eleven mm Cold Rolled Steel Rebars with High Quality | |

Diameter | 5mm, 5.5mm, 6mm, 6.5mm, 7mm, 8mm, 9mm, 10mm, 11mm, 12mm, | |

Length | 6M, 9M, 12M or as required | |

Price | Keep lower operating costs so as to offer competitive price for our clients | |

Label | to be specified by customer, generally, each bundle has 1-2 labels | |

Application | Building, construction | |

Invoicing | Actual or Theoretical Weight Basis as buyer’s request. | |

Theoretical weight and section area of each diameter of Eleven mm Cold Rolled Steel Rebars with High Quality as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m (kg) | Pcs/ton |

11 | 95.0 | 0.746 | 8.952 | 111.71 |

Packaging & Delivery of Eleven mm Cold Rolled Steel Rebars with High Quality:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

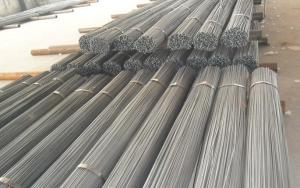

Images of Eleven mm Cold Rolled Steel Rebars with High Quality:

- Q:Can steel rebars be used in structures with high resistance to UV radiation?

- Structures with high exposure to UV radiation typically do not recommend the use of steel rebars. Traditional carbon steel rebars are vulnerable to corrosion when exposed to UV radiation. The sun's rays can degrade the protective oxide layer on the surface of the steel, leading to rust and deterioration over time. Furthermore, UV radiation can cause the steel to expand and contract, weakening its overall strength and structural integrity. To address these concerns, alternative materials like stainless steel rebars or epoxy-coated rebars are commonly employed in structures that require high UV radiation resistance. Stainless steel rebars possess greater corrosion resistance and durability when exposed to UV radiation. Epoxy-coated rebars have a protective layer of epoxy coating that shields the steel from direct UV radiation, mitigating the risk of corrosion. Consulting structural engineers and professionals is crucial in determining the appropriate type of rebars for structures with high UV radiation resistance. Factors such as the specific environment, climate conditions, and project requirements should be carefully considered to ensure the structure's longevity and safety.

- Q:Can steel rebars be used in the construction of underground parking structures?

- Steel rebars are an effective choice for constructing underground parking structures. They are commonly used in reinforced concrete structures, such as underground parking, to reinforce and provide tensile strength. The rebars are strategically placed within the concrete to enhance its load-bearing capacity, durability, and resistance to cracking or deformation. Steel rebars are ideal for underground parking structures that require strong structural support, thanks to their high strength and ability to withstand heavy loads. To further enhance their resistance to corrosion, protective coatings or stainless steel rebars can be applied, which is particularly important in underground environments with moisture and exposure to chemicals. Ultimately, the use of steel rebars is a standard practice in constructing underground parking structures to ensure long-lasting structural integrity.

- Q:Are there any specific guidelines for handling and placing steel rebars in concrete?

- Yes, there are specific guidelines for handling and placing steel rebars in concrete. These guidelines include ensuring proper cleaning, cutting, and bending of rebars, maintaining proper spacing and alignment, securely fastening rebars, and providing adequate concrete cover to prevent corrosion. Additionally, guidelines may vary depending on the project specifications, structural requirements, and local building codes.

- Q:How do steel rebars affect the overall workability of concrete?

- Steel rebars play a crucial role in enhancing the overall workability of concrete. Workability refers to the ease with which concrete can be mixed, placed, compacted, and finished to achieve the desired shape and surface. When steel rebars are incorporated into concrete, they provide reinforcement and improve its structural strength. The rebars act as a skeleton within the concrete matrix and help distribute the loads and stresses evenly throughout the structure. This reinforcement prevents cracking, enhances the structural integrity, and increases the load-bearing capacity of the concrete. Moreover, steel rebars also help control the shrinkage and cracking of concrete. During the curing process, concrete tends to shrink, which can result in the formation of cracks. The presence of rebars mitigates this issue by counteracting the tensile forces that cause shrinkage and cracking, thus improving the overall durability of the concrete. In addition to their structural benefits, steel rebars also facilitate the workability of concrete during the construction process. The rebars act as guides for proper concrete placement and help prevent segregation or separation of the mix. They ensure that the concrete is properly compacted and eliminates potential voids or air pockets, resulting in a more homogeneous and uniform mixture. Furthermore, steel rebars provide stability and support to the concrete during its curing and hardening stages. They prevent deformation or sagging of the fresh concrete and help maintain its desired shape and form. This is particularly important for complex or intricate structures where precise shaping and positioning of the concrete is necessary. Overall, the inclusion of steel rebars positively affects the workability of concrete by enhancing its structural strength, mitigating shrinkage and cracking, facilitating proper placement and compaction, and providing stability during the curing process. The combination of concrete and steel rebars creates a durable and reliable construction material that can withstand various loads and environmental conditions.

- Q:How are steel rebars installed in concrete slabs?

- Steel rebars are typically installed in concrete slabs by first determining the required size, spacing, and layout of the rebars as per structural design requirements. The rebars are then positioned and supported using chairs or spacers to ensure proper concrete cover. Once in place, the rebars are tied together using wire or mechanical connectors to form a reinforcing mesh. Finally, the concrete is poured and allowed to cure, effectively embedding the rebars within the slab to provide added strength and durability.

- Q:What is the process of joining steel rebars together?

- The process of joining steel rebars together is commonly done through methods such as overlap splicing, mechanical splicing, and welding. In overlap splicing, two rebars are overlapped and tied together using wire or steel straps. Mechanical splicing involves using couplers or threaded connectors to join rebars together. Welding, on the other hand, involves melting the ends of two rebars and fusing them together using heat. Each method has its own advantages and considerations, depending on factors like the structural requirements and project specifications.

- Q:What is the purpose of steel rebars?

- The purpose of steel rebars is to reinforce concrete structures, providing strength and stability by counteracting tensile forces and preventing cracks or failure under pressure.

- Q:Can steel rebars be used in architectural or decorative concrete applications?

- Yes, steel rebars can be used in architectural or decorative concrete applications. They provide structural reinforcement and enhance the overall strength and durability of the concrete. Additionally, when properly designed and installed, steel rebars can be concealed or incorporated into the design, making them suitable for various aesthetic purposes in architectural or decorative concrete projects.

- Q:Can steel rebars be used in the construction of theme parks and entertainment venues?

- Yes, steel rebars can be used in the construction of theme parks and entertainment venues. Steel rebars are commonly used in construction projects to reinforce concrete structures, providing strength and durability. In the case of theme parks and entertainment venues, where large crowds gather and safety is paramount, steel rebars can help ensure the structural integrity of buildings, rides, and other facilities.

- Q:How is thread steel made?

- Steel is produced by a small rolling mill, rolling mill main types are divided into: continuous and semi continuous and open train. New and used in the world, mostly continuous small rolling mill. Popular steel mills have universal high-speed rolling mills and 4 slitting high yield mills.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Eleven mm Cold Rolled Steel Rebars with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords