Electrolytic Tinplate of Prime Quality for Chemical Use 0.19mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate of Prime Quality for Chemical Use 0.19mm Thickness Description

Electrolytic Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

2.Main Features of the Electrolytic Tinplate of Prime Quality for Chemical Use 0.19mm Thickness

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

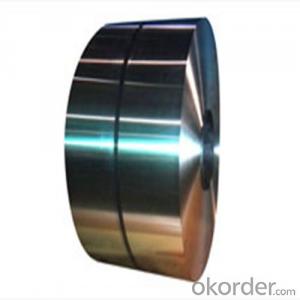

3.Electrolytic Tinplate of Prime Quality for Chemical Use 0.19mm Thickness Images

4.Electrolytic Tinplate of Prime Quality for Chemical Use 0.19mm Thickness Specification

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR

Thickness:0.19mm

Width: 600mm

Temper: T3

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish

5.FAQ of Electrolytic Tinplate of Prime Quality for Chemical Use 0.19mm Thickness

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q:How does tinplate compare to other packaging materials in terms of brand recognition?

- Tinplate is known for its excellent brand recognition due to its ability to be easily customized with vibrant designs and logos. Compared to other packaging materials, such as plastic or cardboard, tinplate stands out and contributes to a stronger brand identity and recall for products.

- Q:What are the safety regulations for tinplate packaging?

- The safety regulations for tinplate packaging are designed to ensure that the packaging material is safe for storing and transporting various products. These regulations typically cover aspects such as the composition of the tinplate, its resistance to corrosion, and any potential hazards associated with its use. Additionally, regulations may also address labeling requirements to provide consumers with information about the contents and potential risks of the packaged products. Compliance with these regulations is crucial to guarantee the safety and integrity of the packaged goods.

- Q:Can tinplate be used for construction materials?

- Yes, tinplate can be used for construction materials, particularly for roofing and cladding applications. Tinplate offers excellent corrosion resistance, durability, and a sleek appearance, making it suitable for various construction projects.

- Q:Can tinplate be used for signage?

- Yes, tinplate can be used for signage. It is a versatile material that can be easily shaped and printed on, making it suitable for various signage purposes.

- Q:What are the printing options for tinplate?

- The printing options for tinplate include lithography, screen printing, and digital printing.

- Q:How do you paint the tinplate?

- Chemical stores have sold, elegant light paint, paint and other various patterns. Don't brush, a keg of a nozzle is put it.

- Q:How is tinplate printed and decorated?

- Tinplate is typically printed and decorated through a process called offset printing. In this method, the design is first engraved onto a metal plate, which is then coated with ink. The inked plate transfers the design onto a rubber blanket, which in turn applies the design onto the tinplate. This process allows for high-quality and precise printing on the tinplate surface. Additionally, after printing, various decorative techniques such as embossing, lacquering, or applying special coatings can be used to enhance the appearance and protect the design on the tinplate.

- Q:What are the recommended soldering techniques for tinplate?

- The recommended soldering techniques for tinplate typically involve using a low temperature solder and a clean, well-heated soldering iron. It is important to pre-tin both the tinplate surface and the soldering iron tip before attempting to join the pieces. Additionally, ensuring a good mechanical connection between the tinplate pieces and using flux to promote better solder flow can greatly improve the soldering results.

- Q:Can tinplate be used for pet food packaging?

- Yes, tinplate can be used for pet food packaging. Tinplate is a common material used in food packaging due to its durability, corrosion resistance, and ability to maintain product freshness. It is also widely recyclable, making it an environmentally friendly choice. Therefore, tinplate is a suitable option for packaging pet food as it provides a reliable and safe container for storing and preserving pet food products.

- Q:What is the process of two cold rolling of tinplate?

- Tinplate is commonly known as tin plated steel sheet. The English abbreviation is SPTE. It is a cold-rolled low carbon steel sheet or strip coated with commercially pure tin on both sides.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrolytic Tinplate of Prime Quality for Chemical Use 0.19mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords