Electrolytic Tinplate of Good Quality for Metal Container 0.15mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate of Good Quality for Metal Container 0.15mm Description

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

2.Main Features of the Electrolytic Tinplate of Good Quality for Metal Container 0.15mm

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

Tinplate is also widely used for making all types of containers such as food cans, beverage cans, and artistic cans, tea cans, painting cans, chemical package cans and dry food package cans, metal printing etc. Its applications are not limited to containers; recently, electrolytic tinplate has also been used for making electrical machinery parts and many other products.

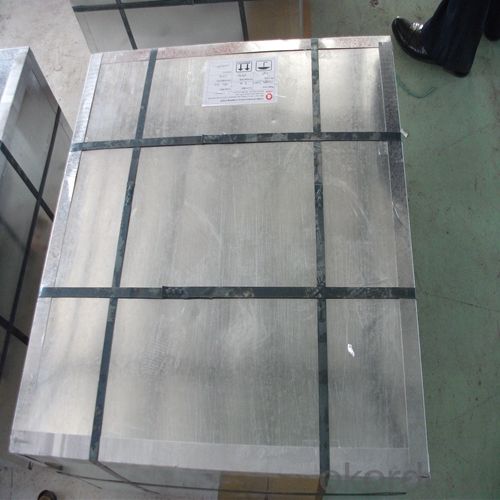

3.Electrolytic Tinplate of Good Quality for Metal Container 0.15mm Images

4.Electrolytic Tinplate of Good Quality for Metal Container 0.15mm Specification

Reference standard: GB2520-88, JIS G3303-1997 and DIN EN10203-91

Material: MR,

Thickness : 0.15mm to 0.45mm

Width available: 600mm to 980mm

Temper grade: T1 - T5 BA and CA both.

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g, We also can produce according to customers' requests

Coil diameter: ID 420/ 508mm, OD from 1,000 to 1,250mm

Package: Anti-rust paper,corner protected. by sheet or coils according customer's require.

Applications: metal package usage like paint, chemical can,aerosol can and different food can production,

Also battery,electric cable and other industries

5.FAQ of Electrolytic Tinplate of Good Quality for Metal Container 0.15mm

1. What is the delivery time for your prime quality tinplate?

Usually 35~40 days after order confirmation.

2. What is your Minimum Order Quantity?

Usually MOQ is 50tons for one single size, for trial order, it can be 25 tons.

3. What is the payment term?

The most common we use is L/C at sight or TT. We can also try use other terms.

- Q:How is tinplate used in the manufacturing of toys?

- Tinplate is commonly used in the manufacturing of toys as it provides a durable and lightweight material for various components. It is often used for packaging, such as toy boxes or containers, as it can be easily shaped and decorated. Additionally, tinplate can be used for creating toy parts, such as miniature cars or robots, due to its malleability and ability to hold intricate designs. Overall, tinplate enhances the aesthetic appeal and functionality of toys, making them more appealing to consumers.

- Q:How does tinplate contribute to the overall convenience of packaging?

- Tinplate contributes to the overall convenience of packaging due to its durability, versatility, and ability to preserve the quality and freshness of products. It provides a protective barrier against moisture, light, and oxygen, which helps extend the shelf life of food and beverages. Additionally, tinplate is lightweight, stackable, and easy to handle, making it suitable for transportation and storage. Its smooth surface allows for easy printing, enabling clear labeling and branding. Overall, tinplate packaging enhances convenience by ensuring the integrity and convenience of various products.

- Q:Can tinplate be used for packaging frozen food?

- Yes, tinplate can be used for packaging frozen food. Tinplate is a type of steel coated with a thin layer of tin, which provides a protective barrier against moisture, oxygen, and other external factors. This makes it an ideal material for packaging frozen food as it helps to maintain the quality and freshness of the product while preventing freezer burn. Additionally, tinplate is also durable and can withstand low temperatures, making it suitable for freezing and storing food items.

- Q:What are the advantages of using tinplate for electrical enclosures?

- There are several advantages to using tinplate for electrical enclosures. Firstly, tinplate is highly resistant to corrosion, which helps protect the sensitive electrical components inside the enclosure from moisture and other environmental factors. Secondly, tinplate offers excellent electrical conductivity, ensuring efficient flow of electricity and minimizing any potential interference or loss. Additionally, tinplate is a lightweight material, making it easier to handle and install. Lastly, tinplate is also recyclable, making it an eco-friendly choice for electrical enclosures.

- Q:How does tinplate withstand corrosion?

- Tinplate withstands corrosion due to the protective properties of tin. The tin coating acts as a barrier between the underlying steel and the surrounding environment, preventing direct contact and oxidation. Tin has excellent corrosion resistance, even in humid and acidic conditions, making tinplate a reliable and durable material for various applications.

- Q:Can tinplate be used for packaging products with sharp edges?

- Yes, tinplate can be used for packaging products with sharp edges as it provides a sturdy and protective barrier that helps prevent damage during transportation and handling.

- Q:What are the main factors influencing the profitability of tinplate manufacturers?

- The main factors influencing the profitability of tinplate manufacturers include the cost of raw materials, such as steel, tin, and other alloys, as well as fluctuations in their prices. Additionally, factors such as energy costs, labor expenses, and transportation costs play a significant role in determining profitability. Market demand and competition also impact profitability, as manufacturers need to adapt to changing market trends and maintain a competitive edge. Furthermore, technological advancements, production efficiency, and economies of scale can influence profitability by reducing production costs and improving overall operational efficiency.

- Q:Can tinplate be used for automotive parts?

- Yes, tinplate can be used for automotive parts. It is a durable material that provides good corrosion resistance, making it suitable for various automotive applications such as body panels, fuel tanks, and exhaust systems.

- Q:Tinplate also known as what? What is the density of it?

- Tinplate, also known as tin plated iron, is the common name for tin plated steel sheet. The English abbreviation is SPTE. It is a cold-rolled low carbon steel sheet or strip coated with commercially pure tin on both sides. The density is 7.85.Tinplate is a tin covered with tin, it is not easy to rust, also known as tin iron.

- Q:How does tinplate contribute to the performance of ammunition?

- Tinplate contributes to the performance of ammunition by providing a protective coating that prevents corrosion and oxidation of the metal components, ensuring the ammunition remains reliable and functional. The tin coating also reduces friction and assists in smooth feeding and extraction, enhancing the overall performance and reliability of the ammunition in firearms.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrolytic Tinplate of Good Quality for Metal Container 0.15mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords