Electrolytic Tinplate in Sheets for Tin Cans Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate in Sheets for Tin Cans Making Description

Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging, is one thin steel sheet with a coating of tin applied by electrolytic deposition. Tinplate made by this process is essentially a sandwich in which the central core is strip steel. This core is cleaned in a pickling solution and then fed through tanks containing electrolyte, where tin is deposited on both sides. As the strip passes between high-frequency electric induction coils, it is heated so that the tin coating melts and flows to form a lustrous coat.

2.Main Features of the Electrolytic Tinplate in Sheets for Tin Cans Making

Appearance – Electrolytic Tin Plate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Electrolytic Tin Plates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Electrolytic Tin Plates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Electrolytic Tin Plates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

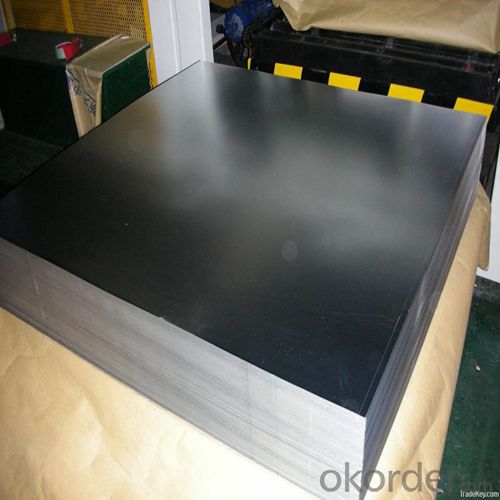

3.Electrolytic Tinplate in Sheets for Tin Cans Making Images

4.Electrolytic Tinplate in Sheets for Tin Cans Making Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Electrolytic Tinplate in Sheets for Tin Cans Making

- How are the Electrolytic Tin Plates specified?

The Electrolytic Tin Plates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q:How does tinplate perform in terms of printability?

- Tinplate performs exceptionally well in terms of printability. Its smooth surface allows for high-quality printing with vibrant colors and fine details. Additionally, the tin coating provides excellent ink adhesion, ensuring sharp and crisp prints.

- Q:What are the typical production volumes for tinplate?

- The typical production volumes for tinplate vary depending on the demand and market conditions, but generally speaking, millions of tons of tinplate are produced annually worldwide.

- Q:What are the main factors influencing the consumer preferences for tinplate packaging?

- The main factors influencing consumer preferences for tinplate packaging include its durability and ability to protect products, its recyclability and sustainability, its aesthetic appeal, the perception of higher quality and prestige associated with it, and the convenience and functionality it offers in terms of storage and opening.

- Q:How does tinplate packaging contribute to brand recognition?

- Tinplate packaging contributes to brand recognition by offering a distinctive and visually appealing presentation of the product. The use of tinplate materials allows for unique designs, vibrant colors, and intricate details that can catch the attention of consumers. This eye-catching packaging helps to create a lasting impression on customers, making them more likely to remember and recognize the brand. Additionally, the durability and premium feel of tinplate packaging can enhance the perceived value and quality of the product, further strengthening brand recognition and loyalty.

- Q:How does tinplate contribute to the protection of agricultural products?

- Tinplate contributes to the protection of agricultural products by providing a highly durable and corrosion-resistant packaging material. It acts as a barrier against moisture, oxygen, and light, preventing spoilage and maintaining the freshness and quality of the agricultural products. Additionally, tinplate packaging offers excellent sealing properties, ensuring the products are protected from external contaminants, pests, and tampering.

- Q:What are the common testing methods for tinplate?

- Common testing methods for tinplate include visual inspection, thickness measurement, hardness testing, adhesion testing, corrosion resistance testing, and coating weight measurement.

- Q:Is tinplate resistant to scratches and dents?

- Yes, tinplate is resistant to scratches and dents.

- Q:How is tinplate coated for household appliances?

- Tinplate is coated for household appliances through a process called electrolytic tinning. In this method, a thin layer of tin is deposited onto the surface of the steel plate through an electrolyte bath. The steel plate acts as the cathode, while the tin serves as the anode. The application of an electric current causes tin ions to migrate and bond with the steel, resulting in a durable and corrosion-resistant coating. This tin coating not only enhances the aesthetics of household appliances but also provides protection against rust and improves their overall lifespan.

- Q:Can tinplate be used for ammunition?

- Yes, tinplate can be used for ammunition. Tinplate is a type of steel plated with a thin layer of tin, which provides corrosion resistance and durability. It is commonly used for manufacturing metal cans, including ammunition containers.

- Q:Can tinplate be used for packaging medical devices?

- Yes, tinplate can be used for packaging medical devices. Tinplate is a strong and durable material that provides excellent protection and barrier properties to ensure the safety and integrity of medical devices. It is also resistant to corrosion and can be easily sterilized, making it suitable for packaging in the medical industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrolytic Tinplate in Sheets for Tin Cans Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords