Electrolytic Tinplate for Useage of Industrial Package

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Electrolytic Tinplate for Useage of Industrial Package Description

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

2.Main Features of the Electrolytic Tinplate for Useage of Industrial Package

The origin of tinplate is from Bohemian, from 14th century, the people there began to produce tinplate. Also known as electrolytic tinplate, which stand for tin coating on the surface of cold rolled coil for preventing rust. The unique characteristics of tinplate steel decides its comprehensive range of application in international tinplate packaging industry. With the abundance extend of CC and DR steel material, and tin free steel, which enhance the development of technology of packaging industrialization, the innovation is ubiquitous in tinplate steel.

The feature of anti-oxidation, various kinds and beauty in printing enable tinplate enjoys widely usage in food can package, pharmaceutical package, daily application packing, apparatus package and industrial pack.

From the first food can to be produced in the year of 1810 in British, the development trend of tinplate has become thinner thickness and less tin coating to adjust the change of can industry and save cost.

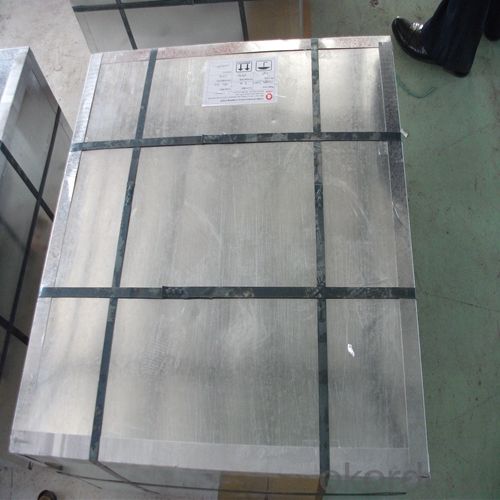

3.Electrolytic Tinplate for Useage of Industrial Package Images

4.Electrolytic Tinplate for Useage of Industrial Package Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Electrolytic Tinplate for Useage of Industrial Package

- What is tinning and how does it work?

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

- Do you only have prime quality tinplate?

We can supply both prime and second quality tinplate.

- Q:What are the different ways to customize tinplate packaging?

- There are several ways to customize tinplate packaging, including printing, embossing, debossing, and adding special finishes. Printing allows for the application of vibrant designs, logos, and artwork directly onto the tinplate surface. Embossing involves creating raised designs or patterns on the packaging, adding a tactile element. Debossing is the opposite, where designs are pressed into the tinplate, creating an indented effect. Special finishes, such as matte or glossy coatings, can also be applied to enhance the overall appearance and protect the packaging.

- Q:How does tinplate contribute to the preservation of aerosol products?

- Tinplate contributes to the preservation of aerosol products by providing a protective and airtight barrier that prevents air, moisture, and light from entering the container. This helps to maintain the product's quality, integrity, and shelf life by preventing oxidation, contamination, and degradation. Tinplate's durability also ensures the can withstand the pressure and impact associated with aerosol dispensing, ensuring safe and reliable use.

- Q:Can tinplate packaging be used for home decor products?

- Yes, tinplate packaging can be used for home decor products. Tinplate is a versatile material that can be easily molded into various shapes and sizes. It provides durability, visual appeal, and can be customized to suit different home decor styles. Additionally, tinplate packaging offers excellent protection for fragile home decor items, making it a suitable choice for packaging and displaying such products.

- Q:What are the main trends in the tinplate industry?

- The main trends in the tinplate industry include a growing demand for sustainable packaging solutions, increasing preference for lightweight and easy-to-recycle materials, advancements in technology for improved tinplate production processes, and the emergence of innovative uses of tinplate in various industries such as food and beverages, cosmetics, and electronics.

- Q:How does tinplate perform in terms of lightness and portability?

- Tinplate is relatively lightweight and portable due to its thin and flexible nature. It can be easily carried and transported, making it a convenient choice for various applications.

- Q:What are the different types of tinplate finishes available?

- There are primarily three types of tinplate finishes available: bright, stone, and matte. Bright tinplate has a shiny and reflective surface, stone tinplate has a textured and grainy appearance, and matte tinplate has a smooth and non-reflective finish. These different finishes offer various aesthetic options for packaging and can be chosen based on the desired look and feel of the final product.

- Q:What are the transportation considerations for tinplate?

- Transportation considerations for tinplate include ensuring proper packaging and securing the tinplate to prevent damage during transit. Due to its susceptibility to corrosion, tinplate should be protected from moisture and extreme temperatures. Additionally, the weight and size of tinplate may impact the choice of transportation method and require careful handling to prevent accidents or injuries.

- Q:What kind of material is tinplate?

- Tin plate is tin plated steel, that is iron.

- Q:What are the main challenges in tinplate coating thickness control?

- One of the main challenges in tinplate coating thickness control is achieving uniformity across the entire surface of the tinplate. The coating thickness must be consistent and within the desired range to ensure proper protection and functionality of the tinplate. Additionally, controlling the coating thickness requires precise measurement and monitoring techniques as well as the ability to adjust the coating process parameters in real-time to account for any variations or deviations. Another challenge is ensuring the adhesion of the coating to the tinplate surface, as poor adhesion can lead to coating defects and reduced performance. Lastly, controlling the coating thickness while maintaining cost-effectiveness can be a challenge, as it requires optimizing the coating process to minimize material waste and reduce production costs.

- Q:What are the main applications of tinplate in the beverage industry?

- Tinplate is widely used in the beverage industry for packaging purposes. It is primarily utilized for manufacturing cans and lids, ensuring the preservation and freshness of various beverages such as carbonated drinks, beer, fruit juices, and canned foods. Tinplate's ability to provide a protective barrier against moisture, light, and air, along with its exceptional resistance to corrosion, makes it an ideal choice for maintaining the quality and shelf life of beverages. Additionally, tinplate cans are lightweight, easy to stack and transport, and can be printed with attractive designs, making them popular for marketing and branding purposes in the beverage industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrolytic Tinplate for Useage of Industrial Package

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords