Electrolytic Tinplate for Chemical Industrial Can Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of ElectrolyticTinplate for Chemical Industrial Can Use Description

Electrolytic Tinplate, is one thin steel sheet with a coating of tin applied by electrolytic deposition. Tinplate made by this process is essentially a sandwich in which the central core is strip steel. This core is cleaned in a pickling solution and then fed through tanks containing electrolyte, where tin is deposited on both sides. As the strip passes between high-frequency electric induction coils, it is heated so that the tin coating melts and flows to form a lustrous coat.

2.Main Features of the ElectrolyticTinplate for Chemical Industrial Can Use

The salient feature of DR Tinplate is the combination of higher strength and sufficient ductility, which enables much thinner Tinplate to be used, compared to Single Reduced Tinplate resulting in Substantial economic savings.

According to the steel chemistry and annealing process, the second reduction (DR08) can be between 27% to 40%, thereby producing strengths upto 550 +/-50 N/mm2, whereas single reduced material has strength less than 450 N/mm2 &DR 09 (Hard DR) is produced at temper mill with reduction % in range of 27-35 % & will strength upto 690 N/mm2 to the produced material.

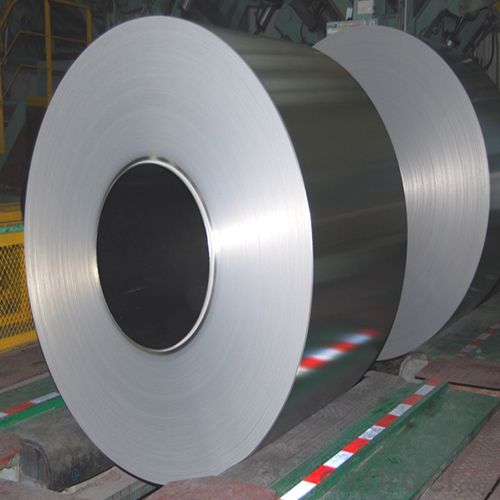

3. ElectrolyticTinplate for Chemical Industrial Can Use Images

4.ElectrolyticTinplate for Chemical Industrial Can Use Specification

Standard: ISO 11949 -1995

Material: MR

Thickness:0.34mm

Width: 600mm

Temper: T3

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish

5.FAQ of ElectrolyticTinplate for Chemical Industrial Can Use

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q:How does tinplate compare to plastic in terms of durability?

- Tinplate generally offers better durability compared to plastic as it is more resistant to breaking, cracking, and bending. Additionally, tinplate is less prone to wear and tear, making it a more long-lasting material.

- Q:Can tinplate be used for promotional items?

- Yes, tinplate can be used for promotional items. Tinplate is versatile and can be easily shaped into various forms, making it suitable for creating promotional items such as tins, cans, boxes, and containers. These items can be customized with branding and logos, making them effective promotional tools for businesses and organizations.

- Q:What are the main competitors of tinplate in the packaging industry?

- The main competitors of tinplate in the packaging industry include aluminum, plastic, and glass.

- Q:Can tinplate be customized with different designs or logos?

- Yes, tinplate can be customized with different designs or logos. It is a versatile material that can be decorated using various printing techniques such as lithography, offset printing, or embossing. This allows for the creation of unique and personalized designs on tinplate, making it suitable for branding and promotional purposes.

- Q:What are the printing options for tinplate?

- The printing options for tinplate include lithography, screen printing, and digital printing.

- Q:What are the common opening mechanisms for tinplate containers?

- The common opening mechanisms for tinplate containers include pull tabs, peelable lids, twist-off caps, and lever lids.

- Q:Can tinplate be used for packaging of organic products?

- Yes, tinplate can be used for packaging of organic products. Tinplate is a durable and non-reactive material that provides a protective barrier against external elements, ensuring the freshness and integrity of organic products. Additionally, tinplate is recyclable, making it an environmentally friendly choice for packaging organic products.

- Q:What are the main countries producing tinplate?

- The main countries producing tinplate are China, Japan, South Korea, and the United States.

- Q:What are the common challenges faced in the production of tinplate?

- Some common challenges faced in the production of tinplate include ensuring consistent tin coating thickness, preventing surface defects such as scratches and dents, maintaining proper adhesion between tin and steel, controlling the tin plating process parameters such as temperature and time, and managing the environmental impact of tinplate production, particularly in terms of waste disposal and chemical usage.

- Q:Can tinplate be used for high-speed packaging lines?

- Yes, tinplate can be used for high-speed packaging lines. Tinplate is known for its strength, durability, and ability to withstand high-speed production processes. It is commonly used in the packaging industry for various applications, including food and beverage cans, aerosol containers, and metal closures. Its smooth surface allows for efficient movement on conveyor belts, and its resistance to corrosion ensures product safety and longevity. Overall, tinplate is an excellent choice for high-speed packaging lines due to its reliability and compatibility with automated production systems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrolytic Tinplate for Chemical Industrial Can Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords