Electrolytic Tinplate Coils or Sheets of Prime Quality for Chemical Use 0.17mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate Coils or Sheets of Prime Quality for Chemical Use 0.17mm Thickness Description

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

2.Main Features of the Electrolytic Tinplate Coils or Sheets of Prime Quality for Chemical Use 0.17mm Thickness

Appearance – Tinplate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Tinplates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Tinplates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Tinplates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

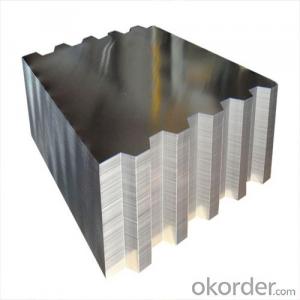

3.Electrolytic Tinplate Coils or Sheets of Prime Quality for Chemical Use 0.17mm Thickness Images

4.Electrolytic Tinplate Coils or Sheets of Prime Quality for Chemical Use 0.17mm Thickness Specification

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR

Thickness:0.17mm

Width: 600mm

Temper: T3

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish

5.FAQ of Electrolytic Tinplate Coils or Sheets of Prime Quality for Chemical Use 0.17mm Thickness

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q:What is the shelf life of tinplate canned goods?

- The shelf life of tinplate canned goods can vary depending on the type of food, packaging integrity, storage conditions, and the specific expiration date indicated on the can. However, in general, properly stored tinplate canned goods can have a shelf life of 1 to 5 years. It is important to check for any signs of damage, bulging, or rust before consuming canned goods to ensure their safety.

- Q:What are the main challenges in tinplate coating?

- One of the main challenges in tinplate coating is achieving consistent and uniform coverage on the surface of the tinplate. This requires specialized equipment and precise control of the coating process parameters, such as temperature, speed, and viscosity of the coating material. Additionally, maintaining adhesion between the tinplate and the coating is another challenge, as any defects or inconsistencies in the adhesion can lead to corrosion or peeling of the coating. Lastly, ensuring that the coating is resistant to external factors such as moisture, chemicals, and abrasion is crucial for the long-term durability and performance of tinplate products.

- Q:What are the main factors affecting tinplate coil storage?

- The main factors affecting tinplate coil storage include temperature, humidity, exposure to moisture, cleanliness of the storage area, and proper stacking techniques.

- Q:What are the limitations of printing on tinplate?

- There are several limitations to printing on tinplate. Firstly, tinplate is not a very smooth surface, which can affect the quality of printed images and text. Additionally, the printing process on tinplate requires specialized inks and equipment, making it more costly and time-consuming compared to printing on other materials. Furthermore, tinplate is prone to scratching and chipping, which can damage the printed design. Lastly, the printing options on tinplate are somewhat limited, as it cannot accommodate intricate or highly detailed designs as well as other printing mediums.

- Q:How does tinplate contribute to the shelf life of beverages?

- Tinplate contributes to the shelf life of beverages by providing a protective barrier against light, oxygen, and moisture, which helps to prevent oxidation and spoilage. This ensures that the beverage retains its quality, taste, and freshness for a longer period of time. Additionally, tinplate cans also have excellent sealing properties, further reducing the risk of contamination and extending the shelf life of beverages.

- Q:How does tinplate contribute to sustainable packaging?

- Tinplate contributes to sustainable packaging as it is 100% recyclable and can be reused indefinitely without losing its properties. It also provides excellent barrier properties, protecting the contents from light, oxygen, and moisture, thus extending the shelf life of the packaged products. Additionally, tinplate is lightweight, reducing transportation costs and emissions.

- Q:How to distinguish galvanized plate and tin plate

- From the outside, hot galvanized, electro galvanized tin plate surface is rough, thick tin layer of light and bright, thin tin layer, hot galvanized galvanized is not only the contest, Matt

- Q:What are the common industry standards for tinplate?

- The common industry standards for tinplate include specifications for the thickness, temper, coating weight, and surface finish. Additionally, the standards outline requirements for the mechanical properties, such as elongation and hardness, as well as the chemical composition of the tin coating. These standards ensure consistent quality and compatibility across different manufacturers and applications in the tinplate industry.

- Q:What are the common safety features for tinplate packaging?

- Common safety features for tinplate packaging include: 1. Tamper-evident closures: Tinplate packaging often includes tamper-evident closures such as seals or breakable tabs that indicate if the product has been opened or tampered with. 2. Child-resistant closures: Many tinplate packages are designed with child-resistant closures to prevent young children from accidentally accessing potentially harmful products. 3. Sturdy construction: Tinplate packaging is known for its durability and strength, providing a protective barrier for the contents inside. 4. Chemical resistance: Tinplate packaging is typically resistant to chemicals, preventing any harmful substances from leaching into the product. 5. Recyclability: Tinplate packaging is highly recyclable, making it an environmentally-friendly choice. This feature ensures that the packaging is disposed of properly, reducing waste and environmental impact. 6. Printed warnings and instructions: Tinplate packaging often includes printed warnings and instructions to inform consumers about any potential hazards associated with the product and how to use it safely. These safety features help to ensure that tinplate packaging protects the product, prevents accidents or tampering, and provides necessary information to consumers for safe usage.

- Q:How is tinplate coated for beverage cans?

- Tinplate is coated for beverage cans through a process known as electrolytic tinplating. This involves immersing the tinplate in an electrolyte solution and passing an electric current through it. The current causes tin ions to be deposited onto the surface of the tinplate, forming a thin and protective layer of tin coating.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrolytic Tinplate Coils or Sheets of Prime Quality for Chemical Use 0.17mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords