Electrolytic Tinplate Coil / Sheet for Foods Can Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging Description

Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging, is one thin steel sheet with a coating of tin applied by electrolytic deposition. Tinplate made by this process is essentially a sandwich in which the central core is strip steel. This core is cleaned in a pickling solution and then fed through tanks containing electrolyte, where tin is deposited on both sides. As the strip passes between high-frequency electric induction coils, it is heated so that the tin coating melts and flows to form a lustrous coat.

2.Main Features of the Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging

Appearance – Electrolytic Tin Plate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Electrolytic Tin Plates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Electrolytic Tin Plates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Electrolytic Tin Plates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

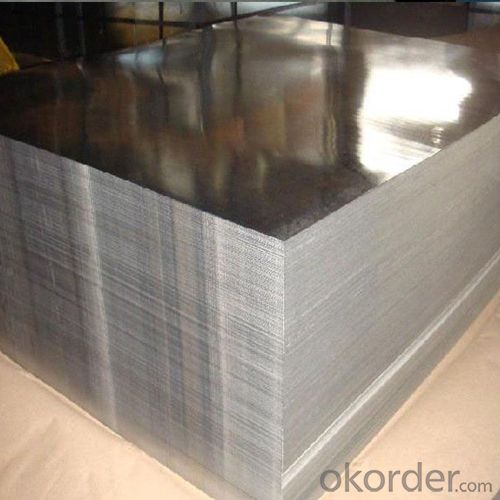

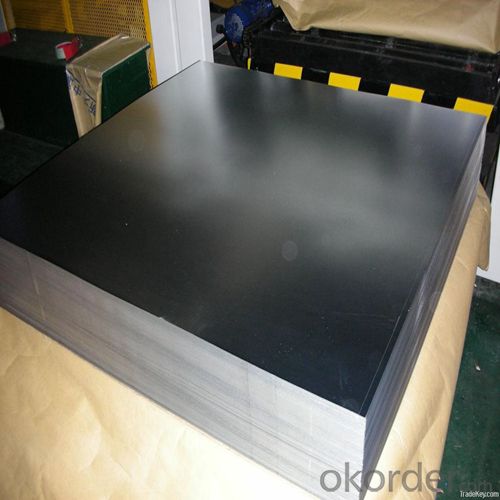

3.Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging Images

4.Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging

- How are the Electrolytic Tin Plates specified?

The Electrolytic Tin Plates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

-What your tinplate material is used for ?

Tinplate is widely used for the packaging of products. Such as food cans,

beverage cans, pet cans, closures, general line cans and so on.

Printed Tinplate is offered!!

-How to place .an order or contact you ?

Please send us Email. we will give you a quick response in seconds .

- How is your quality ?

All our quality is prime even the secondary quality . We have many years experience

In this field with serious quality control standard . Advanced equipment, We welcome your visit to our factory .

- Q:A tin rust problem for help

- Once the outer rust rust, if the area is not large, can use sandpaper to rub the rust, and then wipe clean towel can surface, then coated with a layer of antirust oil; if the outer rust area of about 1/2, we must take into account whether the corrosion to the inner wall, has affected the quality of the contents. If rust occurs on the inside, you need to remove all the rework, tank canning, liquid injection, degassing, sealing and sterilization, cooling, after 2 times of high temperature sterilization of canned products, generally need to downgrade, or if some products in the two sterilization will appear after taste and color changes, you need to direct rejection.

- Q:What are the common decorative options for tinplate packaging?

- Common decorative options for tinplate packaging include printing, embossing, debossing, hot stamping, and lithography. These techniques can be used to create intricate designs, patterns, logos, and text on the surface of the tinplate packaging, making it visually appealing and attractive to consumers.

- Q:Can tinplate be used for medical packaging?

- Yes, tinplate can be used for medical packaging. Tinplate is a durable and corrosion-resistant material, making it suitable for protecting and preserving medical products. It meets the necessary hygiene and safety standards required for medical packaging and can provide an effective barrier against moisture, light, and oxygen. Additionally, tinplate is recyclable, making it an environmentally friendly choice for medical packaging.

- Q:What are the recycling processes for tinplate?

- The recycling processes for tinplate typically involve several steps. First, the tinplate is collected from various sources, such as households or businesses. Then, it is sorted and separated from other materials, such as paper or plastic, through manual or mechanical means. Next, the tinplate is cleaned to remove any contaminants, such as labels or food residue. After cleaning, the tinplate is shredded or melted to reduce it to smaller pieces or molten metal. The molten metal is then cast into new tinplate sheets or other products. This process helps conserve resources, reduce waste, and minimize the environmental impact of tinplate production.

- Q:What are the weight advantages of using tinplate?

- One of the weight advantages of using tinplate is its lightweight nature. Tinplate is made by coating a thin layer of tin onto a steel substrate, resulting in a material that is significantly lighter than other packaging options such as glass or aluminum. This lightweight characteristic makes tinplate an ideal choice for various industries, including food and beverage, where weight reduction is essential for transportation, storage, and overall product cost efficiency.

- Q:How does tinplate perform in terms of light blocking properties?

- Tinplate is known to provide excellent light blocking properties due to its opaque and reflective nature, making it an effective choice for packaging materials to prevent light exposure and preserve the quality of light-sensitive products.

- Q:Can tinplate be used for packaging of flammable liquids?

- No, tinplate is not suitable for packaging flammable liquids as it can easily react with the contents and potentially cause a fire or explosion.

- Q:What are the typical tooling costs for tinplate production?

- The typical tooling costs for tinplate production vary depending on factors such as the complexity of the design, size of the production run, and specific requirements. However, tooling costs for tinplate production can range from a few thousand dollars to tens of thousands of dollars.

- Q:What are the typical lead times for tinplate production?

- The typical lead times for tinplate production can vary depending on factors such as the quantity required, complexity of the design, and the manufacturer's production capacity. However, on average, lead times for tinplate production usually range from several weeks to a few months.

- Q:How is tinplate coated for construction materials?

- Tinplate is coated for construction materials through a process called electrolytic tinning. This involves immersing the steel sheet in an electrolyte bath and passing an electric current through it. The electric current causes tin ions to be reduced and deposited onto the steel surface, forming a thin layer of tin coating. This coating provides corrosion resistance and enhances the durability of the construction materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrolytic Tinplate Coil / Sheet for Foods Can Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords