Electrofusion Flange PE Pipe Fittings EN12201-3

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Electrofusion Flange PE Pipe Fittings EN12201-3

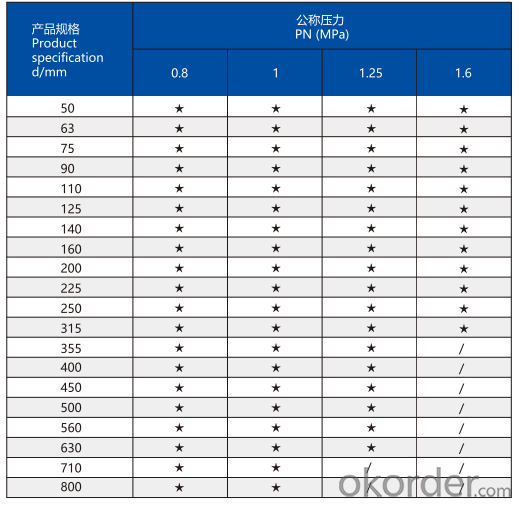

Pressure grade:0.8MPa-1.6MPa

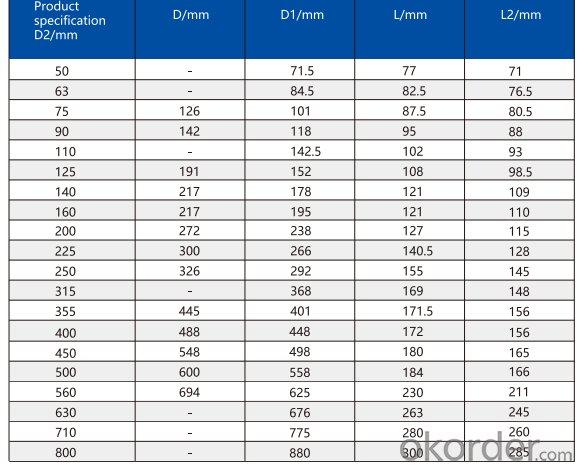

Size: DN50MM-DN800MM

Specification:

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q:Can plastic pipe fittings be used for drainage systems?

- Yes, plastic pipe fittings can be used for drainage systems. Plastic fittings are commonly used in drainage systems due to their durability, corrosion resistance, and ease of installation. They are also cost-effective and provide a reliable solution for managing wastewater and ensuring efficient drainage.

- Q:How do you connect plastic pipe fittings to ABS pipes?

- To connect plastic pipe fittings to ABS pipes, you can use a solvent cement specifically designed for ABS materials. Clean the ends of both the fitting and the pipe, apply the cement evenly to both surfaces, and then firmly push them together. Allow sufficient time for the cement to dry before using the pipe.

- Q:Do plastic pipe fittings have a maximum operating flow rate?

- Yes, plastic pipe fittings do have a maximum operating flow rate. The maximum flow rate is determined by the size and design of the fitting, as well as the type of plastic material used. Exceeding the recommended flow rate can lead to pressure loss, leaks, or even failure of the fitting. It is important to consult the manufacturer's specifications or guidelines to ensure proper usage and avoid any potential issues.

- Q:Can plastic pipe fittings be used for chemical reactors and tanks?

- No, plastic pipe fittings are not suitable for chemical reactors and tanks as they may not have the necessary resistance to withstand the corrosive nature of chemicals and could lead to leaks or failure.

- Q:How do you connect plastic pipe fittings together?

- To connect plastic pipe fittings together, you typically use solvent cement. This adhesive is applied to the outside of the pipe and the inside of the fitting, and then the two pieces are pressed firmly together. The solvent cement creates a strong bond that securely holds the fittings in place.

- Q:Are plastic pipe fittings resistant to mold and mildew?

- Yes, plastic pipe fittings are generally resistant to mold and mildew. Due to their non-porous nature, plastic fittings do not provide a suitable environment for mold and mildew growth. Additionally, plastic materials are often treated with anti-microbial agents or coatings that further inhibit the formation of mold and mildew.

- Q:Can plastic pipe fittings be used in pharmaceutical systems?

- No, plastic pipe fittings are not recommended for use in pharmaceutical systems due to concerns about potential leaching of chemicals or contaminants into the pharmaceutical products. Stainless steel or other suitable materials are typically preferred for such applications to ensure the highest level of safety and quality.

- Q:Are plastic pipe fittings resistant to scaling?

- Yes, plastic pipe fittings are generally resistant to scaling.

- Q:What are the main specifications and sizes of PVC pipe fittings?

- PVC material is a kind of plastic decoration materials, PVC material is referred to as PVC (Polyvinyl Chloride, referred to as PVC) resin is a vinyl chloride monomer (Vinyl Chloride Monomer, referred to as VCM) polymerized thermoplastic polymers. Are made of PVC resin as the main raw material, adding anti-aging agent, modifier, through mixing, calendering, vacuum technology and. PVC is an amorphous polymer, crystal containing the crystallinity 5%--10% (melting point of 175 degrees).

- Q:Can plastic pipe fittings be used for vacuum drainage systems?

- Yes, plastic pipe fittings can be used for vacuum drainage systems. Plastic materials such as PVC or ABS are commonly used in vacuum drainage systems due to their durability, lightweight nature, and resistance to corrosion. These fittings are designed to handle the negative pressure created by the vacuum system, ensuring a reliable and efficient drainage system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrofusion Flange PE Pipe Fittings EN12201-3

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products