Electrical Tinplate, JIS G3303 Standard For Food Cans & Industrial Cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter.

It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

TINPLATE SPECIFICATION

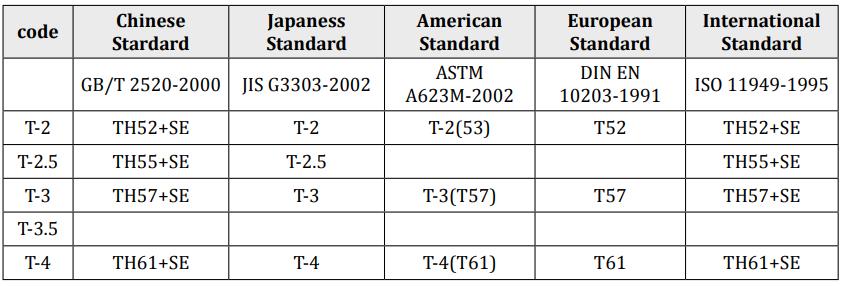

1.Reference standard: GB/T 2520-2000,JIS G3303-2002 and DIN EN 10203-1991

2. Raw material: MR and SPCC

3.Thickness: 0.13 to 0.5mm

4.Width: 600-1050mm

5.Coil diameter: ID 420mm or 508mm

6.Temper: T1~T5,DR8~DR10

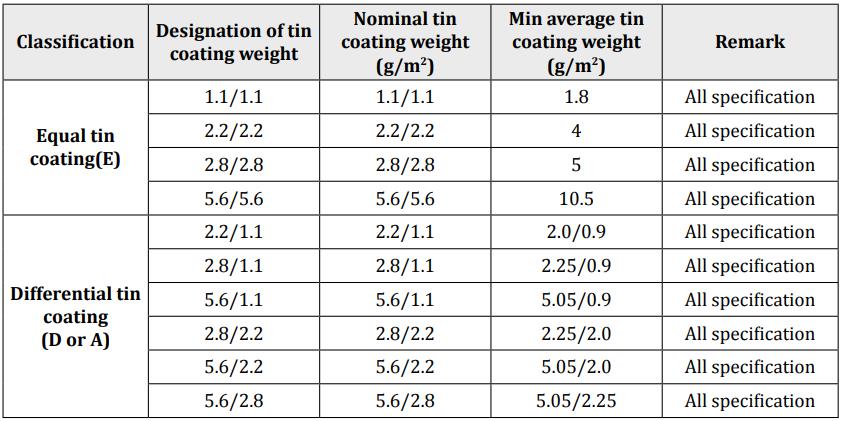

7.Tin coating: 1.1g~11.2g, We can produce according to customer's requests.

8. Applications: paint, chemical and other usage can make battery, electric cable and other industries

9. Package: anti-rust paper, corner protected. Sheets or coils according customer's requests

STANDARD

SURFACE

| Marks | Surface state | Characteristics |

| B | Bright rough | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip featuring certain oriented rubstone figure. |

| RR | St hStone rough | Glazed surface obtained after melting treatment of electrotinned raw material strip featuringg p g certain oriented rubstone figure. |

| S | Silver rough | Glazed surface obtained after melting treatment of electrotinned raw material strip with rough matt surface. |

COATING

APPLICATION

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

- Q:Tinplate why have white and yellow, tin plating should be white ah, yellow is how to return a responsibility?

- Usually on the surface of a layer of oil, light oil, or iron; gold oil is golden; white is white, yellow magnetic, if printing, of course is yellow; usually tinplate can print color (color or 4C file).

- Q:How is tinplate price determined?

- The price of tinplate is determined by various factors including the cost of raw materials, market demand and supply, production and manufacturing costs, as well as any additional taxes or tariffs imposed on the product. Additionally, global economic conditions, exchange rates, and competition within the industry can also influence the pricing of tinplate.

- Q:Why tinned fruit cans, some snow wall, and some inner wall does not appear?

- The same is canned fruit, tin cans taste more than glass bottles, why is it better? Because the storage process is completely isolated from the sun, so that it can retain the original flavor of canned fruit.

- Q:What are the regulations and standards related to tinplate packaging?

- The regulations and standards related to tinplate packaging vary depending on the country and industry. However, some common regulations and standards include specifications on the composition and thickness of tinplate, labeling requirements for product information and safety warnings, guidelines for food contact materials, and regulations for recycling and environmental sustainability. It is important for manufacturers and suppliers to comply with these regulations to ensure the safety and quality of tinplate packaging.

- Q:What are the safety regulations for using tinplate in food packaging?

- The safety regulations for using tinplate in food packaging vary depending on the country. However, generally, tinplate used for food packaging should comply with regulations set by food safety authorities such as the FDA in the United States or the European Food Safety Authority in the European Union. These regulations typically cover aspects such as the use of food-grade coatings, absence of harmful substances, and compliance with specific testing and labeling requirements. It is important for manufacturers to ensure that tinplate used in food packaging meets these safety regulations to ensure the protection of consumers' health.

- Q:How is tinplate coated for construction materials?

- Tinplate is coated for construction materials through a process called electrolytic tin-plating. In this process, a thin layer of tin is applied to the surface of steel or iron sheets by immersing them in an electrolyte bath and passing an electric current through it. This creates a chemical reaction that deposits the tin onto the material, providing it with a protective coating against corrosion and improving its durability for construction purposes.

- Q:Can tinplate be used for coinage?

- No, tinplate cannot be used for coinage as it is not a suitable material for making coins.

- Q:How does tinplate perform in terms of mechanical strength and durability?

- Tinplate exhibits excellent mechanical strength and durability due to its unique composition and manufacturing process. The tin coating adds a protective layer that enhances its resistance to corrosion, making it highly durable even in harsh environments. Additionally, its inherent strength allows it to withstand mechanical stresses, making tinplate a reliable and long-lasting material for various applications.

- Q:What are the main challenges in tinplate recycling?

- One of the main challenges in tinplate recycling is the separation of tin coating from the steel substrate, as the two materials have different melting points. Additionally, the presence of other contaminants such as lacquers and coatings on the tinplate can complicate the recycling process. Furthermore, the collection and sorting of tinplate waste can be challenging due to its prevalence in various product packaging, making it difficult to streamline the recycling system. Overall, technological advancements and increased awareness are necessary to overcome these challenges and improve the efficiency of tinplate recycling.

- Q:What are the main applications of tinplate in the music industry?

- Tinplate is primarily used in the music industry for the production of musical instrument components, such as guitar picks, harmonica reeds, and various percussion instruments. Its corrosion resistance and durability make it an ideal material for ensuring consistent sound quality and longevity of these instruments. Additionally, tinplate is also utilized for the packaging of musical media, such as CDs and vinyl records, providing a protective and attractive casing for music albums.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrical Tinplate, JIS G3303 Standard For Food Cans & Industrial Cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords