Electrical Tape PVC for Wire Harness Wrapping

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Electrical Tape PVC for Wire Harness Wrapping

1. Structure of Wire Harness Tape Description

Wire Harness Tape is of PVC film as the carrier, coating with natural rubber. Wire Harness Tape: widely used as permanent wrapping on cables and wiring harnesses for automobile.

2. Main Features of the Wire Harness Tape

Water resistant and moisture resistant

Self extinguishing

Non-corrosive adhesive

Safety and environmental friendly

Resistant to high temperature

Burning-resistance

3. Wire Harness Tape Images

4. Wire Harness Tape Specification

Item No. | Thickness (micron) | Adhesion to steel (N/cm) | Tensile Strength (N/cm) | Elogation (%) | Teperature Resistance (DC) | Flame Resistance (S) |

PW-11 | 110 | 1.2 | 15 | 150 | 80 | <2< span=""> |

PW-12 | 120 | 1.2 | 16 | 150 | 80 | <2< span=""> |

PW-13 | 120 | 1.2 | 20 | 180 | 80 | <2< span=""> |

PW-15 | 120 | 1.2 | 25 | 200 | 80 | <2< span=""> |

5. FAQ

Q1. Packing and Delivery

Packaging Details: 120 brolls per carton(39*27*30) according to different size

Delivery Detail: 7 to30 days according to different quantity

Q2. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

Q3. What is our company?

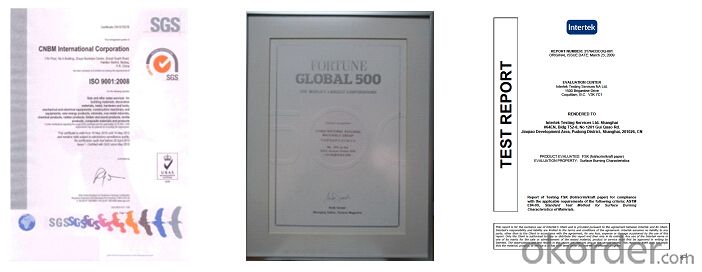

CNBM International Corporation is a state-owned company. As World Top 500 Company, we have clients from over 120 countries and overseas branches in 5 countries. We specialized in adhesive tape for over 20 years, with SGS and ISO9001 certified and Grade AA for Export.

- Q:Is packaging tape resistant to extreme temperatures or weather conditions?

- Yes, packaging tape is designed to be resistant to extreme temperatures and weather conditions. It is typically made with durable materials that can withstand both hot and cold temperatures, as well as protect packages from moisture, rain, and other weather elements.

- Q:Can packaging tape be used for mailing packages?

- Yes, packaging tape can be used for mailing packages. It is commonly used to secure and seal packages, ensuring that they remain intact during transit.

- Q:Are there any specific instructions for reusing packaging tape?

- There exist specific instructions for reusing packaging tape. Here are several guidelines to adhere to: 1. Exercise caution when removing the tape from the package: Upon receiving a package, make an effort to delicately remove the tape in order to prevent tearing or damaging it. 2. Cleanse the tape: Should the tape possess any dirt, dust, or residue, it can be cleansed by gently wiping it with a moist cloth. Allow it to fully dry before reutilizing. 3. Assess the adhesive strength: Before reusing the tape, verify if the adhesive remains sufficiently strong to securely hold. If it has lost its stickiness or sustained damage, it is advisable to discard it and employ a fresh piece of tape. 4. Properly store the tape: To maintain the tape's quality for future use, store it in a cool, dry area away from direct sunlight. This will assist in preventing it from drying out or becoming brittle. 5. Utilize it for light to medium-duty tasks: Reused packaging tape may not possess the same strength as new tape, therefore it is most suitable for lighter to moderately demanding tasks. Avoid utilizing it for heavy items or applications necessitating a stronger adhesive. Bear in mind, while reusing packaging tape constitutes an excellent approach to waste reduction, it is crucial to prioritize functionality and security. If the tape becomes damaged or loses its adhesive strength, it is advisable to replace it with a new piece to ensure proper sealing of your package.

- Q:How do I apply packaging tape evenly?

- To apply packaging tape evenly, follow these steps: 1. Start by ensuring that the surface you are taping is clean and free of any dust, dirt, or moisture. This will help the tape adhere properly. 2. Measure the length of tape you need and cut it accordingly. It is better to have a slightly longer piece of tape than a shorter one. 3. Hold one end of the tape firmly against the surface you are taping and apply it at a slight angle, using gentle pressure. This will help prevent air bubbles and ensure a smooth application. 4. As you continue applying the tape, make sure to keep it taut and straight. Avoid stretching or pulling the tape too tightly, as this can cause it to lose its adhesive properties. 5. Use your fingers or a tape dispenser to press down on the tape firmly, smoothing it out as you go. This will help ensure that it adheres properly and evenly to the surface. 6. If you encounter any wrinkles or bubbles while applying the tape, gently lift the tape and reapply it, smoothing it out as you go. 7. Repeat the process until you have covered the desired area with the tape, making sure to overlap the edges slightly for a secure seal. By following these steps, you should be able to apply packaging tape evenly, creating a neat and secure seal for your packages.

- Q:Can packaging tape be used for mailing packages?

- Absolutely, packaging tape is perfect for mailing packages. Its main purpose is to securely seal packages and guarantee their integrity while in transit. This type of tape is known for its strength and durability, which makes it the ideal choice for securing boxes, envelopes, or any other packaging material. It is widely utilized in shipping and mailing scenarios and comes in different sizes and strengths to adapt to various package dimensions and weights. Regardless of whether you are sending a tiny envelope or a substantial box, packaging tape is an indispensable tool to guarantee the proper sealing and protection of your package throughout the mailing process.

- Q:Is packaging tape resistant to mold or mildew?

- Yes, packaging tape is generally resistant to mold or mildew. Most packaging tapes are made from materials such as polypropylene or vinyl, which do not provide a suitable environment for mold or mildew to grow. These materials are nonporous and waterproof, preventing moisture from seeping through and creating conditions conducive to mold or mildew growth. Additionally, packaging tape is often coated with adhesive that is also resistant to mold or mildew. However, it is important to note that if the tape is applied to a surface that already has mold or mildew present, it may not prevent further growth or eliminate the existing mold or mildew.

- Q:Is packaging tape easy to remove without damaging surfaces?

- Packaging tape is typically designed to be easily removed without causing any harm to surfaces. However, the ease of removal can vary depending on several factors, including the type and quality of the tape, the surface it is applied to, and how long it has been in place. Most packaging tapes are created to stick firmly to surfaces during transportation or storage, ensuring that the package remains sealed and secure. Nevertheless, they are also formulated to be peeled off easily when necessary, without leaving any residue or causing damage. In most situations, packaging tape can be removed by simply peeling it off slowly and evenly. The adhesive used in packaging tapes is generally developed to strike a good balance between sticking power and ease of removal. This allows for effortless removal without the need for excessive force or any sticky residue. However, there may be instances where the tape might be more challenging to remove, particularly if it has been in place for a long time or exposed to extreme temperatures. In such cases, using heat, such as a hairdryer, to soften the adhesive can be helpful, making it easier to peel off. It is important to note that the ease of tape removal can also be influenced by the surface it is applied to. Smooth and non-porous surfaces like glass or metal are generally easier to clean without causing any damage. On the other hand, porous or delicate surfaces like wood or painted walls may require more caution and care during removal to prevent any potential damage. In conclusion, while packaging tape is generally designed to be easily removed without causing damage, it is essential to consider factors such as tape quality, surface type, and removal technique to ensure a smooth and damage-free removal process.

- Q:How does packaging tape perform when exposed to sunlight?

- Packaging tape typically performs well when exposed to sunlight, especially if it is made from durable materials like acrylic or polypropylene. These tapes are designed to resist UV rays and maintain their adhesive properties even when exposed to sunlight for extended periods. However, it is always recommended to check the specifications of the specific tape you are using, as some may have limitations or may be prone to deterioration or discoloration when exposed to direct sunlight for prolonged periods.

- Q:The tape is very loud and loud when it is packed. Would you like to ask me if I have sold silent tape? Or silent tape? Where can I sell it? Thank you

- This silent tape is not available at the moment. If you want a sound spot, try a sticky tape!

- Q:Does packaging tape have any specific safety precautions?

- Yes, packaging tape does have some specific safety precautions that should be followed. Firstly, it is important to handle packaging tape with care and avoid any sharp or sudden movements that could cause injury. While packaging tape itself is not typically dangerous, mishandling it could result in cuts or punctures. Additionally, it is essential to use the appropriate type of packaging tape for the intended purpose. Different tape materials and adhesives are designed for various applications, such as sealing boxes or securing heavy items. Using the wrong type of tape may result in inadequate sealing or potential hazards. Furthermore, it is crucial to store packaging tape in a safe place away from extreme temperatures, moisture, or direct sunlight. These factors can affect the tape's adhesive properties and compromise its effectiveness. Lastly, when using packaging tape, it is advisable to wear protective gloves if necessary, especially when handling sharp or heavy objects. This can provide an extra layer of safety and prevent any potential injuries. By following these safety precautions, users can effectively utilize packaging tape while minimizing the risk of accidents or harm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrical Tape PVC for Wire Harness Wrapping

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords