Electric Galvanised Iron Wire 2.5mm,3.0mm,4.0mm,4.5mm Electric Galvanized Binding Wire

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Electric Galvanised Iron Wire 2.5mm,3.0mm,4.0mm,4.5mm Electric Galvanized Binding Wire Description:

Galvanized Iron Wire has the characteristics of thick zinc coating, good corrosion resistance, firm zinc coating, etc.

Galvanized Iron Wire mainly used in construction, express way fencing, binding of flowers and wire mesh weaving. Galvanized iron wire according to manufacturing technique, it includes hot-dipped galvanized iron wire and electro galvanized iron wire. Mainly telecommunication equipment and materials, medical equipment and device, weaving of wire mesh, steel rope, and filtration mesh, high-pressure pipe, construction, arts and crafts.

2.Main Features of Galvanized Iron Wire:

• Use widely

• Corrosion- resistant

• Durable

• Practical use

• Beauty Surface

• Versatile

3. Galvanized Iron Wire Images

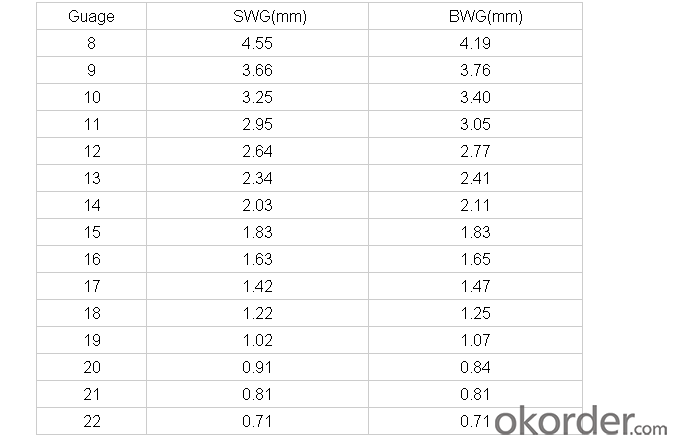

4.Galvanized Iron Wire Specification

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your products?

One of the most biggest manufacturer & supplier of wires and wire mesh,is a large-scale professional Galvanized Iron Wire factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world. Different kinds of wires and mesh are available according to customer’s requirements.

②What is your Technical Information of Galvanized Wire?

1).Material: super carbon steel

2).Processing by drawing, hot-dip zinc-plating

3).Standard wire gauge from 8# to 24#

4).Thick zinc-coating layer

5).Super in corrosion resistance

6).Firm coating layer

7).Custom size available

③How long can we receive the product after payment?

In the purchase of Galvanized Iron Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q:Im cleaning up some of the wires in the engine bay and getting rid of ones i dont use. Right now theresthe pos side bat post runs down to the starter. From the starter there is a thicker wire and a skinny wire. In the thicker wire there is a wire that goes to the post on alternator. Both wires from starter run over to a relay maybe ithas a stud sticking out and has a wire that goes from the bottom of it to the fuse box. Im in middle of relocating the battery into the trunk so what wires can i eliminate and what wires have to go,to the battery?

- Yeah I hate to say it but moving the battery to the trunk is a bad idea. Especially if you don't know what all the wires are there for. Some are grounds others are hot. You switch them you will burn something up.

- Q:A street lamp weighs 200 N. It is supported by two wires that form an angle of 130° with each other. The tensions in the wires are equal.What is the tension in each wire supporting the street lamp?If the angle between the wires supporting the street lamp is reduced to 100°, what is the tension in each wire?

- Problem 1: If the tension in the two wires are equal, the angle they make with the horizontal must also be equal. Always remember that a horizontal line is a straight angle; hence, it has a measurement of 180°. Let's look for the angle the wires make with the horizontal. 130 + x + x = 180 130 + 2x = 180 2x = 180 - 130 2x = 50 (Divide both sides by 2) x = 25° Each wire makes a 25° angle with the horizontal. We can now find the tension. The mass must be divided by 2. Using trigonometry, let's find the tension force. The divided weight of the lamp shall be the opposite side, and the tension force shall be the hypotenuse. sin 25° = (200 / 2) / Ftens Ftens = 100 / sin 25° Ftens = 236.62 N (Answer) The tension is 236.62 N in each wire. Problem 2: We use the same approach. 100 + x + x = 180 100 + 2x = 180 2x = 180 - 100 2x = 80 (Divide both sides by 2) x = 40° Each wire makes a 40° angle with the horizontal. Calculate the tension force. sin 40° = (200 / 2) / Ftens Ftens = 100 / sin 40° Ftens = 155.57 N (Answer) The tension is 155.57 N in each wire. Hope this helps!

- Q:ok, so i love making jewelry, and probably a year ago i went to michael's bought a roll-type thing of really soft, really, really thin silvery wire. a couple of days ago i went to michael's again and it wasn't there.as i said, the wire that i had is very thin, very soft, and also after you bend it, it won't snap back- it actually will never go back to being completely straight, even if you try to make it do that.is memory wire what i should be looking for?does anyone have any suggestions to what kind of wire i should get?

- Hi - I hope this information helps you - Beadalon? Remembrance? is thin, tempered stainless steel wire that is used as a beading medium. The wire is corrosion resistant and will resist tarnishing. Like a spring, Remembrance wire is rigid and snaps back to its original form when expanded and released. The wire remembers its shape and retains its coil form. Sterling Silver Wires To choose the right kind of silver wire for your project, you should know how you want the piece to look and what kind of piece you are creating. You will need to consider both the hardness of the wire and the gauge of the wire. There are three kinds of sterling silver wire. They are: Dead soft, half hard and full hard. Dead soft wire is very easy to bend. It can be better for wire wrapping or for making wire beads but will often not hold shapes intended for wire wrapping. Dead soft silver wire is usually used by people who work silver because it hardens as its shaped and hammered. Half hard sterling wire is stronger than dead soft but is still quite malleable. It is excellent in wire wrapping smaller or heavier beads and is a good choice for beading and jewelry making projects. Full hard silver wire is hard to use and bend and not necessarily recommended for jewelry making - at least for a hobbyist.

- Q:-note-NOT . resistance wire.resistance OF A wire :)lol sorry, just had so many people give me resistance wire.thats not what i want :Li want ..what is the resistance of a wire?its for my science :) pleasee help

- It okorder /... Good luck in your studies, ~ Mitch ~

- Q:For my braces, the top wire where my two front teeth are, I can push the wire and it sort of bend. I don't know if this is normal or not. Can someone tell me?

- Well im 16 and have had my wire braces for 2 years, and all my neighbors have wired braces, but i believe the invisible braces ive seen appear dangerous, like they have somthing on they are tooth. At the least with wired braces everybody knows its braces and no longer some crap you've got on you tooth thats suposed to be invisible.

- Q:Obviously speaker wire is what connects the speaker to the receiver; what's the difference between 'zip' speaker wire and...others...?

- Zip okorder /

- Q:Any instructions on how to make rings, necklaces, and bracelets out of colored telephone wire.

- We okorder /

- Q:There is a circuit with a battery connected to two wires in parallel. Both wires are made of the same material and are of the same length, but the diameter of wire A is twice the diameter of wire B. Answer true or false for the following questionsThe curent through the battery is five times larger than the current through wire B.The power dissipated in wire A is 16 times the power dissipated in wire B.The voltage drop across wire B is larger than the voltage drop across wire A.The resistance of wire B is four times as large as the resistance of wire A.The resistance of wire B is twice as large as the resistance of wire A.

- false false true flase false true -good luck

- Q:how to wire the alternator for a 77 mustang

- the big black wire is you charging wire should go in the battery side of the starter relay the STA post in the alternator goes to terminal S on the voltage regulator the FLD post goes to terminal F on the voltage regulator and there might be a ground wire next to the FLD post on the voltage regulator wire A+ goes to the battery side of the starter relay and wire I goes to the charging indicator light I'm not sure were the voltage regulator is in a mustang but its a square metal box i think it might be on the radiator support or inner finder

- Q:Anyone know which wire behind the navigation unit is the brake wire? I THINK it's pink, but there are multiple pink wires behind the navigation unit.Thoughts?

- Are okorder 's outlander section for a posts on how to disable.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electric Galvanised Iron Wire 2.5mm,3.0mm,4.0mm,4.5mm Electric Galvanized Binding Wire

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords